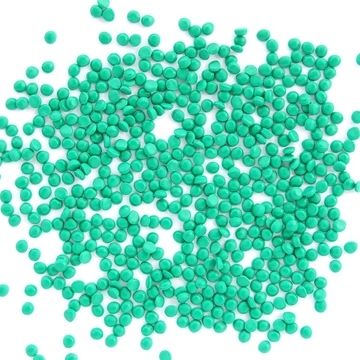

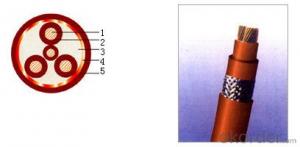

High temperature Resistant PVC compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High temperatureResistant PVC compound for cables

I. Type andapplication

Type | Product | Application and Cable Specification |

2501N | 125 degree C PVC insulating compound | 125 degree C high temperature resistant PVC insulating compound for cables and wires |

2521N | 125 degree C jacket compound | 125 degree C high temperature resistant PVC jacket compound for cables and wires |

II. Product description

High temperature PVC cable compound, basedon PVC resin, is made into granules by mixing, plasticization, and granulation,adding plasticizer, stabilizing agent. The products meet various specialrequirements, such as different hardness, UV stable, environment friendly(RoHs, REACH, PAHs, chlorinated alkanes free)

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 145 | 165 | 175 | 180 | 185 | 180 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage should be clean, cool, dry, andventilated.

V. Properties

Table

Item | Unit | Standard Value | |

2501N | 2521N | ||

Tensile Strength | ≥ MPa | 16.0 | 16.0 |

Elongation at Break | ≥ % | 150 | 180 |

Impact Brittleness Temperature | ℃ | -15 | -25 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1012 | 1.0×108 |

Dielectric Strength | ≥ MV/m | 20 | 18 |

Hot Deformation | ≤ % | 40 | 50 |

Thermal Stability Time at 200℃ | ≥ min | 180 | 180 |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 158±2 | 158±2 |

Aging Time | h | 240 | 168 |

Tensile Strength after aging | ≥ MPa | 16.0 | 16.0 |

Variation on Tensile Strength | % | ±30 | ±25 |

Elongation at Break after aging | ≥ % | 150 | 150 |

Variation on Elongation at Break | % | ±30 | ±25 |

Loss of Mass | ≤ g/m2 | 25 | 25 |

- Q: Is the plastic case transparent or opaque?

- From the convenience of speaking, transparent, easy to organize, easy to see the contents of the collection, and opaque, but need to open the view.

- Q: Are there any disadvantages of using olive nets?

- Yes, there are a few disadvantages of using olive nets. Firstly, olive nets can be quite expensive to purchase and maintain. They require regular cleaning and maintenance to ensure they remain effective. Additionally, olive nets can be time-consuming to set up and take down, especially in larger orchards. They can also obstruct sunlight, potentially affecting the growth and health of the olive trees. Finally, if not properly secured, olive nets can pose a hazard to wildlife and may inadvertently trap or harm birds and other animals.

- Q: Do olive nets require any special installation techniques for densely planted groves?

- Yes, olive nets do require special installation techniques for densely planted groves. In order to effectively protect the olives from birds and other pests, the nets need to be installed tightly and securely to cover the entire grove. This may involve using additional support structures like poles or wires to ensure the nets are properly suspended above the trees. Additionally, it is important to consider the spacing and positioning of the trees to ensure that the nets can be installed and removed easily without causing damage to the plants or the nets themselves.

- Q: How do olive nets prevent olives from being damaged by disease?

- Olive nets prevent olives from being damaged by disease by creating a physical barrier between the olives and external sources of contamination. This helps to reduce the risk of fungal or bacterial infections, as well as the spread of diseases by insects or birds. The nets prevent direct contact of olives with the soil, preventing soil-borne diseases from affecting the fruit. Additionally, the nets provide shade and reduce humidity, creating less favorable conditions for the growth and spread of pathogens.

- Q: Do olive nets require any special maintenance during the off-season?

- Yes, olive nets do require some special maintenance during the off-season. It is important to clean and store the nets properly to ensure their longevity. Cleaning involves removing any debris or dirt from the nets and allowing them to dry thoroughly. Once dry, they should be folded or rolled up neatly and stored in a dry and protected area to prevent damage from moisture or pests. Regular inspection should also be done to check for any tears or damages that need repairing before the next season.

- Q: How do you store olive nets during the off-season?

- During the off-season, olive nets should be properly cleaned and dried before storing them in a cool and dry place. It is recommended to fold them neatly and store them in airtight containers or bags to protect them from dust and pests. Additionally, it is important to ensure that the nets are stored away from direct sunlight to prevent any damage or deterioration.

- Q: What can soften a hardened plastic?

- Thermoplastic structures are linear structures that soften or melt when heated and are plastically made into a definite shape and hardened after cooling. After heating to a certain extent, it softens again and hardens again after cooling. This process can be repeated many times. For example, most plastics, such as PE, PP, PVC, PPR and PS, belong to thermoplastic plastics. Thermoplastic molding process is relatively simple, can be continuous production, and has a high mechanical strength, so the development of very fast.

- Q: Can olive nets be used in combination with organic pest control methods?

- Yes, olive nets can be used in combination with organic pest control methods. Olive nets are primarily used to protect the olive trees from pests like birds and insects. They create a physical barrier that prevents pests from accessing the trees and damaging the fruits. By using organic pest control methods in conjunction with olive nets, such as introducing beneficial insects or using natural repellents, it is possible to further enhance pest management without relying on chemical pesticides.

- Q: Can olive nets be installed by one person?

- Yes, olive nets can be installed by one person. However, the process may be easier and faster with the assistance of another person.

- Q: Plastic shoes taste great, is it harmful?

- Cheap plastic shoes, now generally made of plastic slippers used most of the material is EVA and PVC, basically there will be some so-called "smelly plastic taste, have little effect on the human body, consumers can rest assured to buy.

Send your message to us

High temperature Resistant PVC compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords