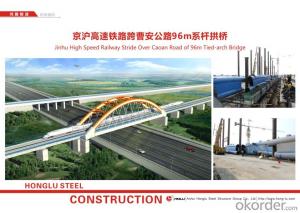

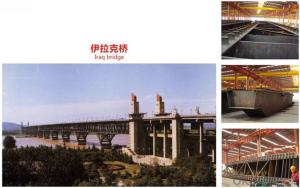

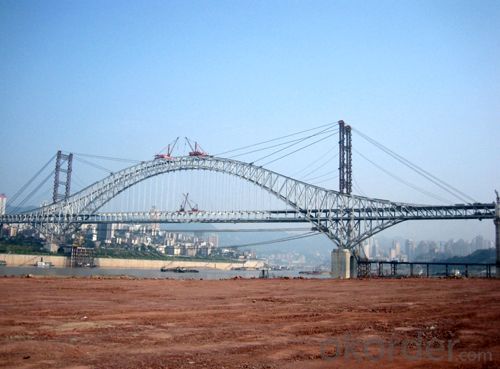

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Model Number | B |

| Material | Metal |

| Drawing for design | According to your requirement.We can quote according to your drawing. |

| Surface Treatment | Hot galvanized,painted,powder coated |

Packing Details

| a)Steel strip. |

| b)According to the customers' requirement |

Payments and Shipping Terms

| MOQ | 25 Ton |

| Supply Ability | 100 ton/Month |

| Payment Term | a)L/C b)T/T |

| FOB Shanghai Price | USD1000-1200/Ton |

Check Below for more imformation on placing an order

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, payment term etc. |

| 3. Our sales send the Proforma Invoice. |

| 4.Customer make the payment for deposit and send us Bank receipt. |

5.We will arrange the production & inform the estimated time. |

6. Middle Production:send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

7. End Production:Mass production products photos will send to you for approval. You can also arrange the third party Inspection. |

8. Clients make payment for balance and we Ship the goods .Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients. |

9. Order can be say “finish” when you receive the goods and satisfy with them . |

10. Feedback to us about Quality , Service, Market Feedback & Suggestion. And we will do better. |

- Q: How are steel structures designed to resist chemical exposure?

- Steel structures are designed to resist chemical exposure through various measures. Firstly, corrosion-resistant coatings or paints are applied to the steel surfaces to provide a barrier against chemical attacks. These coatings are specifically designed to withstand exposure to corrosive chemicals and prevent them from reaching the underlying steel. Additionally, the choice of steel material itself plays a crucial role in resisting chemical exposure. Stainless steel, for example, contains a higher percentage of chromium which forms a protective oxide layer on the surface, providing excellent resistance against corrosion caused by chemicals. Design engineers also consider the layout and ventilation of the structure to minimize the contact of chemicals with steel surfaces. Proper drainage systems are incorporated to prevent accumulation of chemical spills or leaks, reducing the chances of corrosion. Regular maintenance and inspections are crucial to identify any signs of chemical damage and take timely measures to prevent further deterioration. Overall, a combination of suitable coatings, material selection, and careful design considerations help steel structures to effectively resist chemical exposure.

- Q: How are steel structures designed for vibration control?

- Steel structures can be designed for vibration control by incorporating various techniques such as damping systems, vibration isolators, and tuned mass dampers. These methods aim to reduce the dynamic response of the structure to external forces and minimize the transmission of vibrations. Additionally, computer simulations and analysis can be conducted to optimize the design and ensure the structure's ability to withstand vibrations.

- Q: What are the different types of steel grade used in structures?

- There are several types of steel grades commonly used in structures, including carbon steel, alloy steel, stainless steel, and weathering steel. Each type has its own unique properties and characteristics that make it suitable for different structural applications.

- Q: What are the key considerations in the design of steel structures for educational facilities?

- The key considerations in the design of steel structures for educational facilities include factors such as safety, functionality, flexibility, durability, and sustainability. Safety is paramount, with the design needing to meet all relevant building codes and regulations to ensure the protection of students, staff, and visitors. Functionality is crucial, as the design should accommodate various educational activities, from classrooms to laboratories, libraries, and recreational spaces. Flexibility is also important to allow for future expansion or changes in the educational programs. Durability is a key consideration to ensure the longevity of the structure and minimize maintenance costs. Lastly, sustainability plays a significant role in the design, with a focus on energy efficiency, use of sustainable materials, and incorporation of green technologies to minimize the environmental impact of the facility.

- Q: What are the design considerations for steel healthcare campuses?

- Some design considerations for steel healthcare campuses include structural integrity, flexibility for future expansion, infection control measures, efficient space utilization, and accessibility for patients with disabilities. Additionally, incorporating natural light, creating a soothing and healing environment, and implementing sustainable design features are also important considerations.

- Q: What are the different types of steel canopies and walkways used in buildings?

- In buildings, steel canopies and walkways of various types are commonly utilized for different purposes and designs. Here are some of the most prevalent kinds: 1. Cantilever Canopies: These canopies achieve an extended overhang without additional support by relying on a single column or beam. Often found at entrances or outdoor gathering areas, cantilever canopies provide shade and protection from the elements. 2. Truss Canopies: Constructed using interconnected beams, truss canopies create a robust and stable structure. They are commonly used in larger buildings or outdoor spaces where a wide span needs to be covered, such as parking areas or loading docks. 3. Glass Canopies: Designed to offer a transparent and aesthetically pleasing cover for entrances or walkways, glass canopies are often supported by steel frames or cables. This sleek and modern appearance provides protection from the weather. 4. Pedestrian Walkways: Also known as skybridges or footbridges, pedestrian walkways are elevated structures that connect different parts of a building or multiple buildings. These walkways, typically made of steel, offer a safe and convenient passage for people. 5. Covered Walkways: Used to shield pedestrians from rain, snow, or excessive sunlight while moving between different areas of a building or across a campus, covered walkways can have simple structures with a roof supported by steel columns or more intricate designs with walls and additional features. 6. Trellis Canopies: Often used in outdoor spaces like patios, courtyards, or gardens, trellis canopies consist of a lattice-like steel structure that provides partial shade and creates an appealing environment. 7. Tensile Canopies: Distinguished by their design, tensile canopies feature a fabric membrane stretched over a steel framework. This type of canopy offers a lightweight and flexible solution for covering large areas, such as stadiums or outdoor event spaces. When selecting the appropriate type of steel canopy or walkway, it is crucial to consider the specific needs and requirements of the building. Factors such as climate, purpose, design aesthetic, and budget will influence the selection process. Seeking advice from architects, engineers, and construction professionals can aid in determining the most suitable type for a building project.

- Q: How do steel structures contribute to the overall acoustic performance of a building?

- Steel structures can contribute to the overall acoustic performance of a building by providing a rigid and stable framework that minimizes vibration and sound transmission. The inherent strength and stiffness of steel help to reduce the transmission of airborne and impact noise, creating a quieter and more comfortable environment for occupants. Additionally, steel structures can be designed with sound insulation materials and techniques to further enhance the acoustic performance of a building.

- Q: What are the different types of steel mezzanine flooring?

- Various industrial and commercial settings commonly utilize different types of steel mezzanine flooring. These options include: 1. Bar Grating: Interlocking metal bars form this particular type of steel mezzanine flooring. It is highly suitable for environments where liquids or debris may accumulate due to its exceptional drainage, airflow, and visibility. 2. Steel Plate: Solid steel sheets make up the construction of steel plate mezzanine flooring. It is specifically designed for heavy-duty applications or areas with heavy loads, offering high strength and durability. Manufacturing plants, warehouses, and distribution centers frequently utilize this type of flooring. 3. Open Steel Deck: Steel panels with small perforations compose open steel deck mezzanine flooring. This design allows for improved light penetration, ventilation, and minimizes the risk of slipping. It is commonly found in retail stores, offices, and showrooms. 4. Composite Flooring: Composite mezzanine flooring combines steel with other materials like wood, concrete, or fiberglass. It is typically used when additional insulation, noise reduction, or fire resistance is necessary. 5. Resin Coated: Resin-coated mezzanine flooring involves the application of epoxy or polyurethane resins to the steel surface. This coating provides a smooth and slip-resistant surface while offering protection against corrosion and chemicals. Facilities requiring cleanliness and hygiene, such as food processing facilities or pharmaceutical plants, often employ this type of flooring. Overall, the choice of steel mezzanine flooring depends on specific application requirements, such as load capacity, aesthetics, durability, and safety considerations.

- Q: How are steel structures designed to be earthquake-resistant?

- Various engineering techniques and principles are utilized in the design of steel structures to ensure their earthquake resistance. The main objective is to enable the structure to withstand the seismic forces and minimize potential damage. One crucial aspect of earthquake-resistant steel design is the utilization of ductile materials. Steel possesses inherent ductility, allowing it to deform and absorb energy without fracturing. This property allows the structure to flex and dissipate the seismic forces rather than rigidly resisting them. By incorporating ductile materials, the structure can distribute and absorb the seismic energy throughout the building, reducing stress on individual components. The design of the structural system is also a significant factor. Steel structures are typically designed with either a moment-resisting frame system or a braced frame system. Moment-resisting frames facilitate the transfer of seismic forces through the building's beams and columns, utilizing the members' bending capacity to absorb and distribute the forces. On the other hand, braced frames incorporate diagonal bracing elements that enhance the structure's stiffness and resist lateral forces. Additionally, steel structures are designed with redundancy and robustness in mind. Redundancy involves incorporating multiple load paths within the structure, ensuring that if one path fails, there are alternative paths to bear the loads. This redundancy helps prevent the complete collapse of the structure during an earthquake. Robustness refers to the structure's ability to endure damage to specific elements without compromising overall stability. By designing with redundancy and robustness, steel structures can better withstand the unpredictable nature of earthquakes. To further enhance their earthquake resistance, steel structures incorporate various additional elements such as dampers, base isolators, and energy dissipation devices. Dampers are employed to absorb and dissipate the seismic energy, reducing the structure's motion and vibrations. Base isolators, on the other hand, are flexible bearings placed between the foundation and the structure, enabling independent movement of the building during an earthquake. These isolators mitigate the transmission of seismic forces to the structure. Energy dissipation devices, such as friction dampers or viscous dampers, are also employed to absorb and dissipate the energy generated during an earthquake. In conclusion, the earthquake resistance of steel structures is achieved through the utilization of ductile materials, specific structural systems, redundancy, and robustness. By incorporating additional elements like dampers, base isolators, and energy dissipation devices, these structures effectively absorb, distribute, and dissipate seismic forces, minimizing potential damage caused by earthquakes.

- Q: How are steel structures used in the construction of food processing facilities?

- Steel structures are commonly used in the construction of food processing facilities due to their durability, strength, and ability to withstand harsh environmental conditions. These structures provide a stable framework for the facility, supporting heavy machinery and equipment, as well as ensuring the safety of workers and the integrity of the food processing operations. Additionally, steel structures can be easily customized and expanded to accommodate future growth and changes in the facility's layout, making them a cost-effective and flexible choice for food processing construction.

Send your message to us

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords