prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

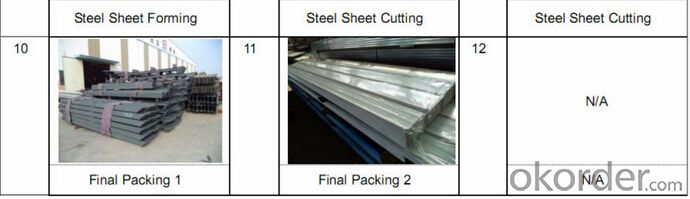

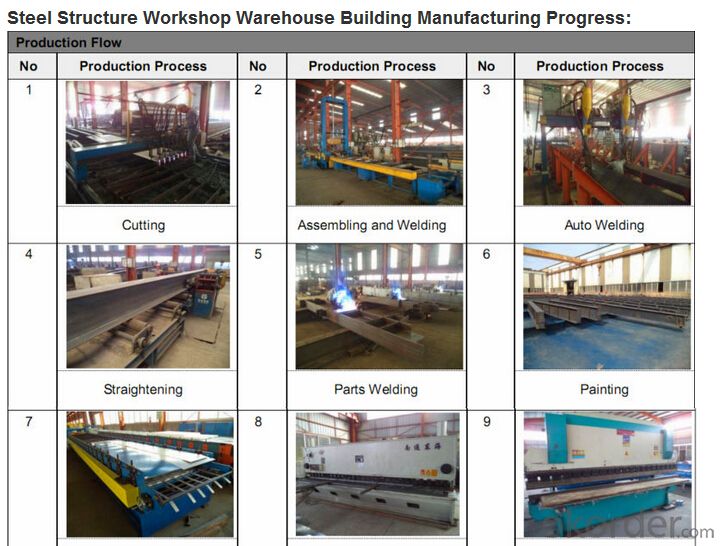

steel structure warehouse/sheds/factory Specifications

Prefabricated House.

Repeat use and long life.

Anti-rust.low cost

| Material | C Purlin, H Beam, Sandwich panel, Hot Galvanised Steel, etc. |

| Features | 1. Firm and Artistic |

| 2. Durable for 30 years at least. | |

| 3. Reusale, and Easy to intall and dismantle: usually, one worker could install 20-30 square meters per day, six workers could work out 3K*10K houses in two days. | |

4. Extensive Applications: Warehouse, Plant, Exhibition Hall, Terminal Building, Stadium, Theater, Special-shaped Buildings. | |

| 5. Hot Galvanised… | |

| 6.Flexible composition: Doors and Windows could be installed at any positions,Separate Walls could be built at any transverse axis. Stairs could be outside Steel buildings. |

- Q:What are the different types of steel stairs and railings used in structures?

- Various structures commonly utilize several types of steel stairs and railings, including: 1. Straight stairs: These are the most basic and widespread staircase type, consisting of a straight flight connecting two levels without any turns or curves. 2. L-shaped stairs: Also known as quarter-turn stairs, these are designed to change direction at a landing. They are commonly used in limited spaces or when a change in direction is necessary. 3. U-shaped stairs: Also referred to as half-turn or switchback stairs, these consist of two parallel flights changing direction at a landing, creating a U-shape. They are often employed in larger structures with ample space. 4. Spiral stairs: Compact and visually appealing, these stairs have steps spiraling around a central column. They are commonly used in structures with limited space or as decorative elements. 5. Cantilevered stairs: This modern and minimalist design gives the impression of floating stairs. Supported by a concealed structure, such as a wall or beam, they do not require visible support underneath. 6. Glass railings: These are a popular choice for contemporary structures due to their unobstructed view and sleek appearance. Often combined with steel frames or posts for added strength and stability. 7. Cable railings: These consist of tensioned horizontal or vertical cables between steel posts. They offer a minimalist aesthetic and are commonly used in contemporary structures or areas where visibility is crucial, such as balconies or outdoor decks. 8. Pipe railings: Made of steel pipes, these railings are commonly found in industrial or commercial structures. They are durable, easy to install, and provide a sturdy and functional railing option. Ultimately, the selection of steel stairs and railings depends on the specific requirements of the structure, architectural design, and personal preferences. Different types of steel stairs and railings offer various options in terms of functionality, aesthetics, and space utilization.

- Q:How are steel structures used in the construction of art galleries?

- Steel structures are commonly used in the construction of art galleries due to their strength, durability, and versatility. They provide a sturdy framework for the building, allowing for large open spaces and flexible layouts to display artwork. Steel beams and columns can support heavy loads, enabling the construction of multi-story galleries or expansive exhibition halls. Additionally, steel's fire-resistant properties make it an ideal material for ensuring the safety of valuable art collections.

- Q:What are the different types of steel stairs and handrails used in buildings?

- Buildings commonly use various types of steel stairs and handrails. These include: 1. Straight stairs: These are the most prevalent type, found in both residential and commercial buildings. They consist of a single straight flight of steps that connect different levels. 2. L-shaped stairs: Named for their shape, these stairs have a straight flight that turns 90 degrees at a landing or platform. 3. U-shaped stairs: Similar to L-shaped stairs, U-shaped stairs have two flights that turn in opposite directions, forming a U shape. 4. Spiral stairs: A visually appealing option for buildings with limited space, spiral stairs have a central pole with steps spiraling around it. 5. Circular stairs: Comparable to spiral stairs, circular stairs have wider and more spacious steps. They are often used in grand entrances or large buildings. 6. Exterior stairs: Designed to withstand outdoor weather conditions, exterior stairs are commonly used for entrances, balconies, or fire escapes. 7. Handrails: Essential for safety, handrails are typically made of steel and provide support and stability while using the stairs. They can be straight, curved, or custom-designed to match the building's style. Overall, architects and designers consider factors such as available space, building design, functionality, and safety requirements when selecting the most suitable steel stairs and handrails for a specific project.

- Q:How is the structural integrity of steel structures ensured during construction?

- The structural integrity of steel structures is ensured during construction through various measures. Firstly, detailed structural engineering analysis and design are conducted to determine the appropriate size and shape of the steel members. This ensures that the structure can withstand the intended loads and forces. During construction, careful attention is given to the fabrication and installation of the steel components. Skilled welders and fabricators ensure that the welding and connections between steel members are done correctly, following industry standards and codes. This includes proper inspection of welds to ensure their quality and strength. Additionally, regular inspections and quality control checks are performed throughout the construction process. This helps identify any potential defects or issues that could compromise the structural integrity. Non-destructive testing methods like ultrasound, X-ray, or magnetic particle inspection may also be used to detect any hidden flaws or weaknesses in the steel. Furthermore, strict adherence to safety protocols and construction standards is essential to ensure the integrity of steel structures. Regular monitoring and supervision by qualified professionals help ensure that the construction is carried out according to the approved plans and specifications. Overall, a combination of careful design, skilled fabrication and installation, thorough inspections, and adherence to safety protocols help to ensure the structural integrity of steel structures during construction.

- Q:How are steel structures designed to be resistant to corrosion in industrial settings?

- Steel structures in industrial settings are designed to be resistant to corrosion through various methods. One of the most common methods is the use of protective coatings. These coatings can be applied to the steel surface to create a barrier between the metal and its surroundings, preventing corrosive substances from coming into direct contact with the steel. Examples of protective coatings include paint, epoxy, and galvanizing. Paint coatings are often used as a first line of defense against corrosion. They provide a protective layer that seals the steel surface, preventing moisture and chemicals from reaching the metal. Epoxy coatings, on the other hand, are more durable and resistant to chemicals, making them suitable for harsh industrial environments. Galvanizing is another effective method to protect steel structures from corrosion. It involves coating the steel with a layer of zinc, which acts as a sacrificial anode. When the zinc layer comes into contact with corrosive substances, it corrodes instead of the steel, thereby protecting it. Galvanizing is particularly useful in environments with high humidity or exposure to saltwater. In addition to protective coatings, steel structures can also be designed with features that minimize the risk of corrosion. For example, proper drainage systems can be incorporated to prevent the accumulation of water on the steel surfaces. This reduces the likelihood of corrosion caused by prolonged exposure to moisture. Regular maintenance and inspection are also crucial in ensuring the long-term corrosion resistance of steel structures in industrial settings. This includes routine cleaning, inspection of coatings for signs of damage or wear, and timely repair of any defects or damages. By following these practices, steel structures can maintain their integrity and resistance to corrosion, ensuring their longevity in harsh industrial environments.

- Q:What are the design considerations for steel healthcare campuses?

- Some design considerations for steel healthcare campuses include structural integrity, flexibility for future expansion, infection control measures, efficient space utilization, and accessibility for patients with disabilities. Additionally, incorporating natural light, creating a soothing and healing environment, and implementing sustainable design features are also important considerations.

- Q:How are steel structures designed for thermal comfort?

- Various strategies can be employed to achieve thermal comfort in steel structures, aiming to regulate internal temperature and enhance occupants' comfort. Insulation is a key consideration, as effective insulation materials incorporated into the walls, roofs, and floors of steel structures can minimize heat transfer, reducing heat gain or loss from the external environment. This insulation helps maintain a stable internal temperature, minimizing the need for excessive heating or cooling. Efficient HVAC systems are another aspect of thermal comfort design for steel structures. These systems can be tailored to provide adequate heating or cooling based on the specific requirements of the building and its occupants. By ensuring proper airflow and temperature control, occupants can enjoy a comfortable indoor environment throughout the year. The orientation and placement of windows and shading devices are also important design considerations. By strategically positioning windows to maximize natural light while minimizing direct sunlight exposure, passive solar heating can be utilized to provide additional warmth during colder months. Shading devices like blinds or overhangs can also help prevent solar heat gain during warmer months, preventing overheating. The selection of appropriate building materials plays a crucial role in steel structure design for thermal comfort. For example, using high-performance glazing with low solar heat gain coefficients can help reduce unwanted heat transfer. Additionally, incorporating thermal mass materials like concrete or stone in the building envelope can regulate temperature fluctuations by absorbing and releasing heat gradually. Lastly, advanced technologies such as smart controls and energy management systems can optimize energy consumption and enhance thermal comfort. These systems can monitor and adjust temperature, humidity, and ventilation levels based on occupancy patterns and weather conditions, ensuring a comfortable and energy-efficient indoor environment. In conclusion, achieving thermal comfort in steel structures involves implementing insulation, efficient HVAC systems, strategic window placement, shading devices, appropriate building materials, and advanced technologies. Architects and engineers can create steel structures that promote a comfortable and sustainable living or working environment by considering these factors.

- Q:How are steel structures used in power plants and industrial facilities?

- Due to their durability, strength, and versatility, steel structures find extensive use in power plants and industrial facilities. In power plants, these structures serve various purposes in supporting the heavy machinery and equipment necessary for power generation. Boilers, turbines, generators, and cooling towers are commonly constructed using steel frameworks due to its high load-bearing capacity, enabling them to withstand the immense weight and stress exerted by these components. Furthermore, steel structures are also employed in power plant buildings such as control rooms, administration offices, and storage facilities. These structures provide a stable and secure environment for personnel, equipment, and important documents. The fire-resistant properties of steel are particularly valuable in power plants as they help mitigate the risk of fire hazards. Likewise, in industrial facilities, steel structures play a crucial role in supporting heavy manufacturing equipment, conveyors, and overhead cranes. They offer a stable platform for machinery operation, ensuring safety and efficiency. Additionally, steel structures are frequently used in the construction of warehouses, workshops, and production areas, allowing for spacious open spaces and adaptable layouts to accommodate various industrial processes. Moreover, steel structures provide numerous advantages in power plants and industrial facilities. They exhibit high resistance to corrosion, a vital characteristic in environments where exposure to chemicals, moisture, and harsh conditions is common. Additionally, steel structures boast a long lifespan, reducing the need for frequent maintenance and replacement. In conclusion, steel structures are indispensable in power plants and industrial facilities due to their ability to provide necessary support, durability, and versatility for heavy machinery and equipment. They ensure the safety, efficiency, and long-term functionality of these facilities, making steel an essential material in the power and industrial sectors.

- Q:What are the different types of steel stairs in a structure?

- In a structure, there are several different types of steel stairs that can be used. These include: 1. Straight stairs: This is the most common type of steel stairs, where the steps run in a straight line from top to bottom. They are simple in design and are often used in residential or commercial buildings. 2. L-shaped stairs: These stairs have a landing at a 90-degree angle, forming an L shape. They are ideal for spaces with limited room or for creating a visual break in staircases. 3. U-shaped stairs: U-shaped stairs have two flights of stairs that turn 180 degrees, creating a U shape. They are commonly used in larger buildings or homes with multiple levels. 4. Spiral stairs: Spiral stairs are compact and take up less space compared to other types. They have a central column and steps that curve around it. They can be visually appealing and are often used in homes or buildings with limited space. 5. Floating stairs: Also known as cantilever stairs, these stairs appear to be floating without any visible support. They are achieved by attaching the steps to a hidden steel frame or a wall, giving a sleek and modern look. 6. Industrial stairs: Industrial stairs are designed to be sturdy and durable, suitable for heavy-duty use in industrial or commercial settings. They often have open risers and non-slip treads for safety. 7. Fire escape stairs: These stairs are specifically designed as emergency exits in case of a fire or other emergencies. They are usually located on the exterior of buildings and are made to be easily accessible and safe in emergency situations. Each type of steel stair has its own advantages and is chosen based on the specific requirements of the structure and its intended use. Factors such as space availability, design aesthetic, safety regulations, and budget considerations are taken into account when selecting the appropriate type of steel stairs for a structure.

- Q:Can steel structures be designed with solar panel installations?

- Yes, steel structures can be designed with solar panel installations. Steel is a versatile and strong material that can support the weight and load of solar panels while providing a durable framework for their installation. Steel structures can be specifically designed to accommodate solar panels, ensuring proper placement and orientation for maximum energy generation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords