NU208 Cylindrical roller Bearings mill roll bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Cylindrical roller bearings:

Cylindrical roller bearings belong to separable bearings, whose inner and outer rings are linearly contacted with rollers. They have small friction coefficient, bigger capacity of bearing radial load and are applicable to both bearing heavy load and impact load and high-speed rotation. Cylindrical roller bearings have the advantages of compact structure, strong stiffness, big bearing capacity, small deformation after loaded etc.

CNBM has already successfully developed split cylindrical roller bearings which can be freely installed at any time and any place, to meet the demand of driving and conveying rollway bearings at cooling area of continuous casting. CNBM also can provide special cylindrical roller bearings according to requirement of customers.

Product Application:

- Iron and steel metallurgical industry

- Medium and large motor

- Generator

- Combustion engines

- Machine tool spindle

- Speed reducer

- Loading and unloading machinery and all kinds of industrial machinery

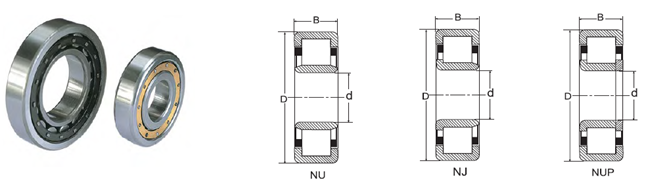

Single row cylindrical roller bearings

- NU, N single row cylindrical roller beaings

NU type and N type allows axis relative the cage within the scope of certain to do axial movement, it would adapt for thermal expansion or installation error caused by the shaft and housing relative position changes, they suit to use for free end bearing. Because they can not limit shaft and the shell axial displacement, and can only bear the radial load.

- NJ, NF single row cylindrical roller bearings

Both NJ and NF can bearing single direction axial load in a certain extent.

- NUP single row cylindrical roller bearings

NUP type bearings with double outer rid, single inner rid and loose rid, this design is possible to limit the axial displacement of the shaft or the housing in double direction within the scope of the axial clearance. in addition they mainly used to bear radial load, also can withstand diameter, the axial union load. Therefore this NUP suitable for fixed end bearings.

- NCL…V single row cylindrical roller bearings

No outer rim but with double lock ring without cage cylindrical roller bearing.

The bearing no cage, roller number is more, and size of the same other cylindrical roller bearing is able to withstand the big radial direction load, but its limit rotational speed is low. The bearing inner ring and outer inseparable, cannot install respectively, can limit shaft or housing of the two directions of the axial displacement in bearing axial clearance within the limit.

| Bearing No. | d | D | B(mm) | Weight(kg) | Bearing No. | d | D | B(mm) | Weight(kg) | |||||

| NU202 | 15 | 35 | 11 | 0.047 | ||||||||||

| NU203 | 17 | 40 | 12 | 0.068 | ||||||||||

| NU204 | 20 | 47 | 14 | 0.110 | NU304 | 20 | 52 | 15 | 0.150 | |||||

| NU205 | 25 | 52 | 15 | 0.130 | NU305 | 25 | 62 | 17 | 0.240 | |||||

| NU206 | 30 | 62 | 16 | 0.200 | NU306 | 30 | 72 | 19 | 0.360 | |||||

| NU207 | 35 | 72 | 17 | 0.300 | NU307 | 35 | 80 | 21 | 0.480 | |||||

| NU208 | 40 | 80 | 18 | 0.370 | NU308 | 40 | 90 | 23 | 0.650 | |||||

| NU209 | 45 | 85 | 19 | 0.430 | NU309 | 45 | 100 | 25 | 0.900 | |||||

| NU210 | 50 | 90 | 20 | 0.480 | NU310 | 50 | 110 | 27 | 1.150 | |||||

| NU211 | 55 | 100 | 21 | 0.660 | NU311 | 55 | 120 | 29 | 1.450 | |||||

| NU212 | 60 | 110 | 22 | 0.810 | NU312 | 60 | 130 | 31 | 1.800 | |||||

| NU213 | 65 | 120 | 23 | 1.050 | NU313 | 65 | 140 | 33 | 2.250 | |||||

| NU214 | 70 | 125 | 24 | 1.150 | NU314 | 70 | 150 | 35 | 2.750 | |||||

| NU215 | 75 | 130 | 25 | 1.250 | NU315 | 75 | 160 | 37 | 3.300 | |||||

| NU216 | 80 | 140 | 26 | 1.500 | NU316 | 80 | 170 | 39 | 3.950 | |||||

| NU217 | 85 | 150 | 28 | 1.900 | NU317 | 85 | 180 | 41 | 4.700 | |||||

| NU218 | 90 | 160 | 30 | 2.350 | NU318 | 90 | 190 | 43 | 5.450 | |||||

| NU219 | 95 | 170 | 32 | 2.850 | NU319 | 95 | 200 | 45 | 6.250 | |||||

| NU220 | 100 | 180 | 34 | 3.450 | ||||||||||

| NU221 | 105 | 190 | 36 | 4.000 | ||||||||||

| NU222 | 110 | 200 | 38 | 4.800 | ||||||||||

- Q: How are the twin row cylindrical roller bearings classified?

- Classification of double row cylindrical roller bearings:The NN0000 type cylindrical roller bearingsThe bearings are compact in structure and small in deformation under load, so they are especially suitable for the support of the spindle of machine tools. Because of its no outer wall, so you can install the outer ring and the inner ring assembly respectively (with roller and cage), does not limit the axial displacement of the shaft or housing, compared with the single row cylindrical roller bearing with the same radial size, can bear larger radial load.

- Q: Which column roller bearing brand is good?

- Foreign SKF is better, the domestic is Kazakhstan axis, and then is Taiwan's Rui Rui, you can look at yourself, they recently in the Qingdao market to great influence, you can understand.

- Q: How to check the thrust cylindrical roller bearings?

- This data is the minimum axial load, not the maximum axial load.

- Q: Can you make it clear? I don't understand. Thank you for being here first.

- A rolling body is a short cylinder.The inner ring (or outer ring) of the bearing can be split.

- Q: What is the limit speed and rated dynamic load of NSK full M40-19g cylindrical roller bearings, HTF?

- D - tapered roller bearings with a contact angle of 28 degrees. C, CA (with solid brass cage), CD (with stamping cage), spherical roller bearing with high load. E -- high load cylindrical roller bearing. H - thrust roller bearing high load. J - tapered roller bearings of the outer raceway, the small end diameter, angle, outer ring width is consistent with the provisions of ISO. (2) material G - ring, rolling body is carburizing steel. H - ring, roll for stainless steel. (3) holder M - copper alloy solid cage. T - synthetic resin cage. W - press holder. V - no cage. (4) sealing ring, dust cover Z, ZS - one side with steel plate dust cover. ZZ, ZZS -- dust cover for two side steel plate. D, DU - one side contact rubber ring. DD, DDU -- two faced contact rubber ring. V - one with a non-contact rubber ring. VV -- two side non-contact rubber sealing ring. (5) ring shape K - taper hole, taper 1:12. K30 -- taper hole, taper 1:30. E - there is a notch or oil hole in the ring. E4 - oil tank with oil holes on the outer ring. N -- outside outer diameter band stop groove. NR -- outer ring, outer band, stop groove, stop ring.

- Q: What are full cylindrical roller bearings?

- Full cylindrical roller bearingCommon cylindrical roller bearings1, single row full cylindrical roller bearingsNCFNJG2 、 double row full cylindrical roller bearingNNCLNNCFNNCNNFTwo, not common full cylindrical roller bearings1, full spherical cylindrical roller bearings2, CARB ring roller bearings

- Q: What's the difference between imported bearings and imported bearings?

- Domestic bearings used in the cage and rivet and washer, spacer ring, sealing ring, pillar, pin etc. the material is divided into black metal materials (such as low carbon steel, stainless steel etc.), non-ferrous metal materials (such as brass, bronze and Aluminum Alloy etc.) and non metal materials (such as plastics, phenolic textolite three) etc..

- Q: What are the components of cylindrical roller bearings?

- Compared with the deep groove ball bearings of the same size, this kind of bearing has larger radial load capacity, and is also suitable for high-speed rotation from the structure.

- Q: What kind of material is used for cylindrical roller bearings?

- Ah, you ask what material to do, of course, with the bearing steel do ah. Bearing steel, however, is well distributed. Generally use GL15#

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 3, the bearing clearance in different conditions: the bearing clearance can be changed under different conditions, in particular, can be divided into: 1) the original clearance: the original bearing clearance refers to the complete installation in front of the machine after the bearings, the clearance in a free state of the. In fact, the original clearance is not to be measured by measurement, so the original clearance is often replaced by a test clearance. The inspection is in clearance inspection status, applied in measuring load conditions, clearance data instruments detection and, strictly speaking with the original bearing clearance is not the same, but little difference in the readings on the two in general, so it can replace each other without causing much error. 2) effective clearance: effective clearance, or work clearance, refers to the bearing in the installation of the host, in a certain load, to a certain temperature rise in a stable state of operation, bearings exist in the actual clearance. Obviously, the effective clearance is smaller than the original clearance.And 4, bearing clearance: clearance of bearing is to ensure that the bearings are to operate flexibly without blocking, but also requires that can ensure the bearing running smoothly, the bearing axis has no significant settlement, and the number of rolling elements bear the load as much as possible. Therefore, the clearance of the bearing has a great influence on the dynamic performance of the bearing (noise, vibration and friction) and the rotation accuracy, and the carrying capacity (wear and fatigue) of the bearing.

Send your message to us

NU208 Cylindrical roller Bearings mill roll bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords