NU206 Cylindrical roller Bearings Cylindrical Roller Bearing mill roll bearing NU bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Cylindrical roller bearings:

Cylindrical roller bearings belong to separable bearings, whose inner and outer rings are linearly contacted with rollers. They have small friction coefficient, bigger capacity of bearing radial load and are applicable to both bearing heavy load and impact load and high-speed rotation. Cylindrical roller bearings have the advantages of compact structure, strong stiffness, big bearing capacity, small deformation after loaded etc.

CNBM has already successfully developed split cylindrical roller bearings which can be freely installed at any time and any place, to meet the demand of driving and conveying rollway bearings at cooling area of continuous casting. CNBM also can provide special cylindrical roller bearings according to requirement of customers.

Product Application:

- Iron and steel metallurgical industry

- Medium and large motor

- Generator

- Combustion engines

- Machine tool spindle

- Speed reducer

- Loading and unloading machinery and all kinds of industrial machinery

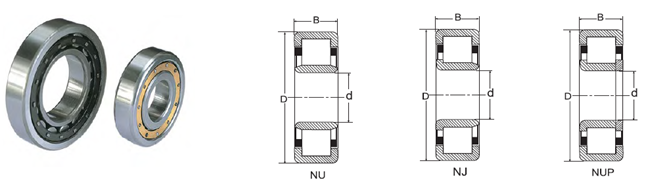

Single row cylindrical roller bearings

- NU, N single row cylindrical roller beaings

NU type and N type allows axis relative the cage within the scope of certain to do axial movement, it would adapt for thermal expansion or installation error caused by the shaft and housing relative position changes, they suit to use for free end bearing. Because they can not limit shaft and the shell axial displacement, and can only bear the radial load.

- NJ, NF single row cylindrical roller bearings

Both NJ and NF can bearing single direction axial load in a certain extent.

- NUP single row cylindrical roller bearings

NUP type bearings with double outer rid, single inner rid and loose rid, this design is possible to limit the axial displacement of the shaft or the housing in double direction within the scope of the axial clearance. in addition they mainly used to bear radial load, also can withstand diameter, the axial union load. Therefore this NUP suitable for fixed end bearings.

- NCL…V single row cylindrical roller bearings

No outer rim but with double lock ring without cage cylindrical roller bearing.

The bearing no cage, roller number is more, and size of the same other cylindrical roller bearing is able to withstand the big radial direction load, but its limit rotational speed is low. The bearing inner ring and outer inseparable, cannot install respectively, can limit shaft or housing of the two directions of the axial displacement in bearing axial clearance within the limit.

| Bearing No. | d | D | B(mm) | Weight(kg) | Bearing No. | d | D | B(mm) | Weight(kg) | |||||

| NU202 | 15 | 35 | 11 | 0.047 | ||||||||||

| NU203 | 17 | 40 | 12 | 0.068 | ||||||||||

| NU204 | 20 | 47 | 14 | 0.110 | NU304 | 20 | 52 | 15 | 0.150 | |||||

| NU205 | 25 | 52 | 15 | 0.130 | NU305 | 25 | 62 | 17 | 0.240 | |||||

| NU206 | 30 | 62 | 16 | 0.200 | NU306 | 30 | 72 | 19 | 0.360 | |||||

| NU207 | 35 | 72 | 17 | 0.300 | NU307 | 35 | 80 | 21 | 0.480 | |||||

| NU208 | 40 | 80 | 18 | 0.370 | NU308 | 40 | 90 | 23 | 0.650 | |||||

| NU209 | 45 | 85 | 19 | 0.430 | NU309 | 45 | 100 | 25 | 0.900 | |||||

| NU210 | 50 | 90 | 20 | 0.480 | NU310 | 50 | 110 | 27 | 1.150 | |||||

| NU211 | 55 | 100 | 21 | 0.660 | NU311 | 55 | 120 | 29 | 1.450 | |||||

| NU212 | 60 | 110 | 22 | 0.810 | NU312 | 60 | 130 | 31 | 1.800 | |||||

| NU213 | 65 | 120 | 23 | 1.050 | NU313 | 65 | 140 | 33 | 2.250 | |||||

| NU214 | 70 | 125 | 24 | 1.150 | NU314 | 70 | 150 | 35 | 2.750 | |||||

| NU215 | 75 | 130 | 25 | 1.250 | NU315 | 75 | 160 | 37 | 3.300 | |||||

| NU216 | 80 | 140 | 26 | 1.500 | NU316 | 80 | 170 | 39 | 3.950 | |||||

| NU217 | 85 | 150 | 28 | 1.900 | NU317 | 85 | 180 | 41 | 4.700 | |||||

| NU218 | 90 | 160 | 30 | 2.350 | NU318 | 90 | 190 | 43 | 5.450 | |||||

| NU219 | 95 | 170 | 32 | 2.850 | NU319 | 95 | 200 | 45 | 6.250 | |||||

| NU220 | 100 | 180 | 34 | 3.450 | ||||||||||

| NU221 | 105 | 190 | 36 | 4.000 | ||||||||||

| NU222 | 110 | 200 | 38 | 4.800 | ||||||||||

- Q: KOYO cylindrical roller bearings, //KOYO cylindrical roller bearings, how to determine the accuracy level?

- The allowable deviation of 1, the inner and outer diameter, width and the width of the assembly allowable deviation 2, roller diameter and the outer round round in group 3, the diameter of the chamfer size bounds value 4, the width of the allowable rotation accuracy (momentum and rotating body beating related projects) 1, inner ring and the outer ring allows for radial and axial beating 2, inner ring 3, allowing the lateral runout of outer surface inclination to allow changes in volume 4, the thickness of the thrust bearing raceway permissible variation

- Q: Which column roller bearing brand is good?

- you can look at yourself, they recently in the Qingdao market to great influence, you can understand.

- Q: Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- Double row cylindrical roller bearings have no directionality, so they do not need to pay attention to the direction! However, it should be noted that the inner ring and outer ring should be positioned separately to prevent axial movement!

- Q: Attention problems of cylindrical roller bearings

- High temperatures often indicate that cylindrical roller bearings are in exceptional condition. High temperature is also harmful to bearing lubricants. Sometimes the bearing is overheated and can be attributed to the lubricant in the bearing. If the bearings are longer than the temperature of 125 degrees, even the transfer will reduce the bearing life. The causes of high temperature bearings include: insufficient lubrication or excessive lubrication, impurities in the bearing raceway, extreme high speed, long term overload operation of bearings, etc..

- Q: Double row cylindrical roller bearings how to disassemble?

- If it is replaced, use the flame to heat it quickly under the conditions permitted! The inner ring is heated and expanded and removed rapidly; flame cutting is used directly.

- Q: What are full cylindrical roller bearings?

- Full cylindrical roller bearingCommon cylindrical roller bearings1, single row full cylindrical roller bearingsNCFNJG2 、 double row full cylindrical roller bearingNNCLNNCFNNCNNFTwo, not common full cylindrical roller bearings1, full spherical cylindrical roller bearings2, CARB ring roller bearings

- Q: Is the roller bearing and the bearing chamber movable in the tapered rotor motor?

- E in cylindrical roller bearing is the meaning of improving internal cage design, similar to the SKF cylindrical roller bearing EC form, this type of bearing than without E, is to strengthen the design, the roller is filled more larger to increase the load. From the load point of view, it is better to choose E.

- Q: What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?

- What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?Semi convex, convex roller is in plane roller axis, the outer surface of a continuous or discontinuous convex curved basic cylindrical or conical roller, to prevent the end of the roller and raceway contact stress concentration. The roller is generally defined as a convex roller and a modified roller.

- Q: Full use roller bearings

- The service is applied to all axle box bearings, including FAG cylindrical roller bearings, spherical bearings and tapered roller NSK bearings. In addition, FAG industry services also provide support to customers in the rail industry who introduce maintenance management systems. INA bearing agent Chinese by helping clients improve internal maintenance procedures, F IS can enhance the data exchange between various departments, and clearly useless procedures, such as entry in IT system and database in different kinds of data. This reduces the cost of raw material management and speeds up maintenance activities. NSK it is very important for the effective maintenance management to install the bearing units rapidly and effectively in china. At the same time, the F IS offers a range of energy saving bearing heaters. Including the FAG Powertimken series induction heater, to enable customers to reduce the installation time of bearing, NSK bearings so as to shorten the downtime, instead of using the traditional heating method (oil bath heating stove, or board). FAG is a research and development partner and supplier of the world's leading Boeing 787 manufacturer. The quality, reliability and efficiency of Schaeffler's aviation bearings, INA bearings, price fits, and performance in extreme conditions, the INA bearing agent provides support for the international space navigation corporation. FAG's bearing technology is used on almost all modern aircraft.

- Q: The Russian bearing suffix No. ZST is a cylindrical roller bearing

- Well, you have to write out the whole model. The suffix code is not used to distinguish the bearings, but it helps to explain the structure of the bearings and the material.

Send your message to us

NU206 Cylindrical roller Bearings Cylindrical Roller Bearing mill roll bearing NU bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords