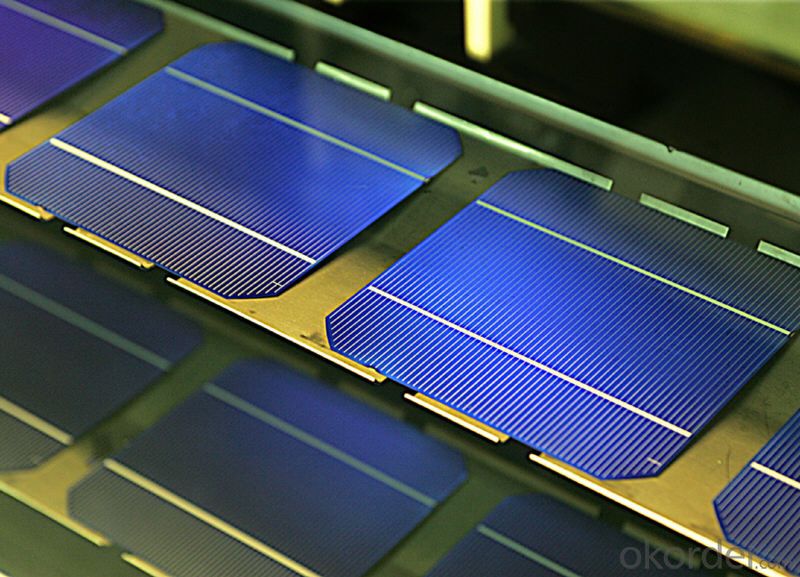

Silicon Wafer in Solar Photovoltaic Cells - Mono Solar Cells 156mm*156mm in Bulk Quantity Low Price Stock 19.8

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

- Up to 20.0% efficiency, one of the highest performing mono crystalline cells on the market

- Three bus bars boosts current collection over the entire cell area, leading to higher fill factors

- Blue anti-reflecting coating allows more sunlight be captured and converted to electricity

- Finer, closer fingers improves charge collections for improved energy yield

- Lower light-induced degradation leads to greater power output over the entire module lifetime

- All solar cells are tightly classified to optimize output of module

- Maximum yield and longevity due to hotspot prevention

- Premium appearance results in a highly uniform and aesthetically appealing module

Specification

- Product Mono-crystalline silicon solar cell

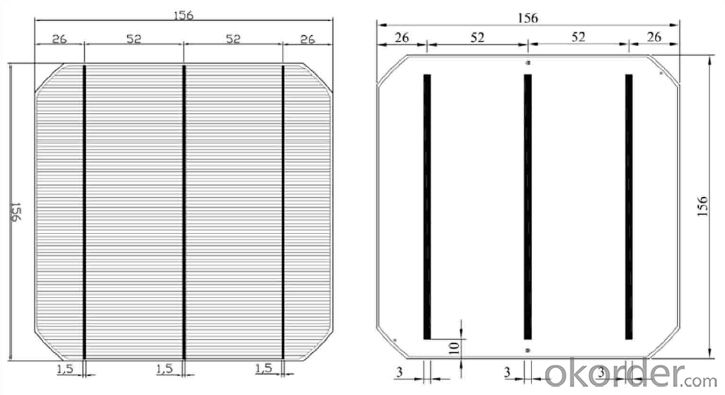

- Dimension 156 mm x 156 mm ± 0.5 mm

- Thickness 200 μm ± 30 μm

- Front 1.5 ± 0.1 mm busbar (silver)

- Silicon nitride antireflection coating

- Back 3.0 mm continuous soldering pads (silver)

- Back surface field (aluminum)

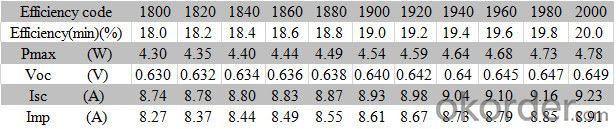

Electric performance parameters

- Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

- Imin : at 0.5 V

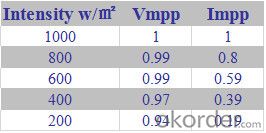

Light Intensity Dependence

Soldering Ability

- Peel Strength: > 1.0 N/mm (Pull soldered ribbon from busbar in 5 mm/s of 180°)

Dimension Figure

Quick Response

- Any time and anywhere, reply clients' email and solve all problems happen in the work at the first time.

- Remove clients doubts and offer the best solution at the first time.

- Give our clients the lastest news of the photovoltaic, update the newest stock informtion.

Production and Quality Control

- Precision cell efficiency sorting procedures

- Stringent criteria for color uniformity and appearance

- Reverse current and shunt resistance screening

- ISO9001,ISO14001 and OHSAS 18001,TUV Certificated

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q: How are solar silicon wafers cleaned before assembly into solar cells?

- Solar silicon wafers are typically cleaned through a multi-step process before assembly into solar cells. This process involves several cleaning methods such as ultrasonic cleaning, acid cleaning, and chemical treatments. Initially, the wafers are placed in an ultrasonic bath to remove any particles or impurities on their surface. Subsequently, acid cleaning is performed to eliminate any remaining contaminants. Finally, chemical treatments are employed to enhance the wafers' surface properties and improve their efficiency. Overall, this meticulous cleaning procedure ensures the high quality and optimal performance of solar silicon wafers before their assembly into solar cells.

- Q: What is the role of a junction box connector in a solar silicon wafer?

- The role of a junction box connector in a solar silicon wafer is to provide a secure and efficient electrical connection between the solar cells on the wafer and the external circuitry. It acts as a junction point where the individual solar cells are connected in series or parallel to form a complete solar module. The junction box connector also ensures protection against environmental factors such as moisture and dust, and may include diodes to prevent reverse current flow.

- Q: What is the purpose of a microinverter in a solar silicon wafer?

- The purpose of a microinverter in a solar silicon wafer is to convert the DC (direct current) power generated by the solar panel into AC (alternating current) power, which is the type of electricity used in households and the power grid. The microinverter also allows for individual optimization and monitoring of each solar panel, increasing overall system efficiency and performance.

- Q: How do solar silicon wafers perform in areas with limited sunlight?

- Solar silicon wafers perform less efficiently in areas with limited sunlight compared to regions with abundant sunlight. The generation of electricity from solar panels is directly dependent on the amount of sunlight they receive. Therefore, in areas with limited sunlight, solar silicon wafers produce less electricity, resulting in reduced energy generation.

- Q: Why should the wafer cut side, cut out edge Jiaosha

- In fact, early silicon is not cutting edge, but with the development of microelectronics industry began the following reasons: cutting edge, W2) i: J n$W% L* M1 s `&;1, n can do a plurality of microelectronic devices on the wafer, cut down, and there is a crystal to crystal growth requirements, cutting along a direction for cutting chaos crack, cleavage is the professional said. The cutting edge tells you the direction of cleavage.2, N type and P type silicon wafer, a standard trimming is also inform you that it is n type or P type electrical characteristics, electrical characteristics, u$J2 z/ h 9 - O3, microelectronics production has been automated, such as lithography exposure if there is no cutting edge positioning, then the mask plate and the chip will be a difference of 180 degrees or a certain location, production efficiency will be very low...,4, the use of a lot of silicon, in addition to n/p also have crystal direction, for example, do MEMS requires corrosion anisotropy will be used <110> crystal direction, and MOS products in order to reduce the influence of the surface state requirements with <100> crystal...

- Q: What is the cost of a solar silicon wafer?

- The cost of a solar silicon wafer can vary depending on various factors such as the size, quality, and quantity ordered. On average, a standard 156 mm x 156 mm solar silicon wafer can cost around $0.20 to $0.50 per piece. However, it's important to note that prices may fluctuate due to market conditions and other factors.

- Q: What are the advantages of using a solar silicon wafer in solar cells?

- There are several advantages of using a solar silicon wafer in solar cells. Firstly, silicon is abundantly available, making it a cost-effective material for producing solar cells. Secondly, silicon has excellent electrical properties, allowing for efficient conversion of sunlight into electricity. Additionally, silicon is a stable and durable material, ensuring the longevity and reliability of solar cells. Lastly, silicon wafers can be easily manufactured in various sizes and shapes, providing flexibility in designing solar cell modules for different applications.

- Q: Can solar silicon wafers be used in rooftop solar installations?

- Yes, solar silicon wafers can be used in rooftop solar installations. Silicon wafers are the most common material used in the production of solar cells, which are then assembled into solar panels for rooftop installations. These panels are designed to capture sunlight and convert it into electricity, making them an ideal choice for harnessing solar energy on rooftops.

- Q: What is the role of back surface field in solar silicon wafers?

- The role of back surface field in solar silicon wafers is to enhance the efficiency of the solar cell by reducing the recombination of charge carriers at the back surface. It creates a strong electric field at the back surface, which helps to collect the minority carriers and improve the overall performance of the solar cell.

- Q: How are solar silicon wafers etched to enhance light absorption?

- Solar silicon wafers are etched to enhance light absorption through a process called texturization. This involves using an etching solution, such as a mixture of hydrofluoric acid and nitric acid, to etch the surface of the silicon wafer. The etching solution removes small amounts of silicon, creating microscopic pyramids or bumps on the surface. These surface textures help trap and scatter incoming light, increasing the chances of absorption by the silicon material and improving the overall efficiency of the solar cell.

Send your message to us

Silicon Wafer in Solar Photovoltaic Cells - Mono Solar Cells 156mm*156mm in Bulk Quantity Low Price Stock 19.8

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords