Cheapest Solar Cells Per Watt

Cheapest Solar Cells Per Watt Related Searches

Cheap Solar Cells Cheap Solar Cells For Sale Low Cost Solar Cells Buy Cheap Solar Cells Affordable Solar Cells Cost Solar Cells Lightest Solar Cells Solar Module Price Per Watt Solar Module Cost Per Watt Cost Of Solar Cells Cheap Solar Cells China Cheap Solar Inverter Cheap Solar Power Inverter Best Solar Cells Buy Small Solar Cells Best Solar Cells To Buy Cost Of Silicon Solar Cells Price Of Silicon Solar Cells Cheap Solar Micro Inverter Solar Inverter Price Per Watt Best Solar Cells On The Market Are Solar Cells Expensive Cost Of Solar Cells Over Time Price Of Solar Cells Over Time Lightweight Solar Cells Buy Solar Cells Solar Module Prices Best Solar Cells In The World Cost Of Organic Solar Cells Solar Inverter Low PriceCheapest Solar Cells Per Watt Supplier & Manufacturer from China

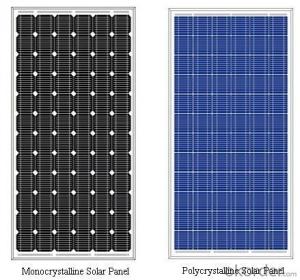

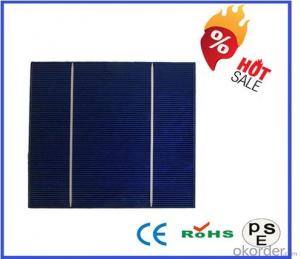

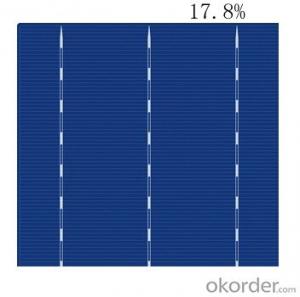

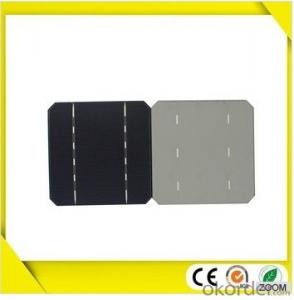

Cheapest Solar Cells Per Watt are photovoltaic devices that convert sunlight into electricity, making them an eco-friendly and cost-effective solution for harnessing renewable energy. These solar cells are widely used in various applications such as residential rooftops, commercial buildings, and large-scale solar power plants, providing a sustainable source of power for both small and large-scale energy needs. They are designed to maximize energy output while minimizing costs, making them an attractive option for those seeking to invest in solar technology.The usage scenarios for Cheapest Solar Cells Per Watt are diverse, ranging from powering remote homes and off-grid locations to supporting the energy demands of urban centers. They are also utilized in various industries, such as agriculture for irrigation systems and in the telecommunications sector for maintaining base station operations. These solar cells offer a reliable and efficient way to harness solar energy, reducing dependency on fossil fuels and contributing to a cleaner environment.

Okorder.com is a reputable wholesale supplier of Cheapest Solar Cells Per Watt, boasting a large inventory that caters to the varying needs of customers worldwide. With a commitment to quality and competitive pricing, Okorder.com ensures that businesses and individuals have access to high-performance solar cells at the most affordable rates. Their extensive range of products and services make them a go-to source for those looking to invest in solar energy solutions.

Hot Products