Longi High Energy Conversion Efficiency Monocrystalline Silicon Solar Cells with Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

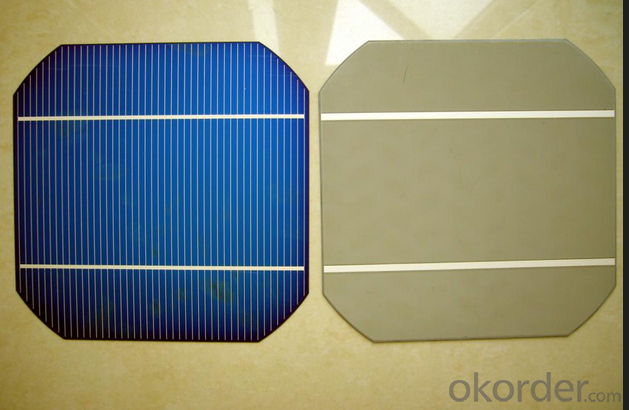

1. Monocrystalline Silicon Solar Cells

OKorder is offering high quality Monocrystalline Silicon Solar Cells at great prices with worldwide shipping. Solar cells are the core of solar power systems and our Monocrystalline solar cells consist of an anisotropically texturized surface and dark silicon nitride, anti-reflection coating and a full-surface aluminum back-surface field. These Monocrystalline solar modules are perfect for converting solar energy into electric energy, or charging storage batteries.

2. The intended use of Monocrystalline Silicon Solar Cells

Our Monocrystalline Silicon Solar Cells are ideal for:

Power generation

Lighting

3. The advantages of Monocrystalline Silicon Solar Cells

Not only are OKorder's Monocrystalline Silicon Solar Cells of the highest quality and reliability, we are able to quickly ship orders within 20 days of receiving a deposit or original L/C.

4. Main features of Monocrystalline Silicon Solar Cells

Extended service life

Outstanding power output even in low light or high temperature conditions

High energy conversion efficiency

Reliable performance

Color uniformity

Low breakage rate

Optimized design for ease of soldering and lamination

5. FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What is a solar cell?

A: A solar cell is an electrical device that converts light energy directly into electricity by a phenomenon called the photovoltaic effect. When exposed to light, solar cells can generate and support an electric current without being attached to any external voltage source, but do require an external load for power consumption.

Q3: What are the advantages and disadvantages of monocrystalline solar PV cells?

A: Monocrystalline solar cells are the most efficient type of PV cells, with the exception of CdTe thin film solar PV cells. As a result, monocrystalline solar cells are more expensive when compared to almost all other types of cells.

Q4: What is the typical service life of solar PV modules?

A: The typical life of a PV module is 25 years. However, superior quality PV modules boast service lives up to 35-40 years (electrical generating capacity is often reduced, however by that point).

Q5: What certifications do you have?

A: We are specialized in the photovoltaic field, with a focus on solar cells, modules and photovoltaic power generation systems. We employ advanced monocrystalline and polycrystalline silicon solar cell manufacturing equipment, producing highly efficient and reliable products sold in Europe, the Americas and Australia. Our company has passed ISO9001 quality management system certification, and our products have obtained TUV-IEC, CE, UL certification.

Q6: How do we guarantee the quality of our products?

A: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q7: How soon can we receive the product after purchase?

A: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

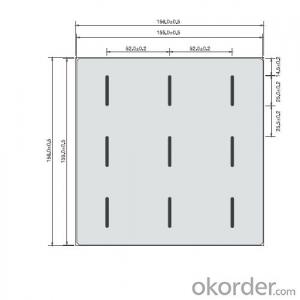

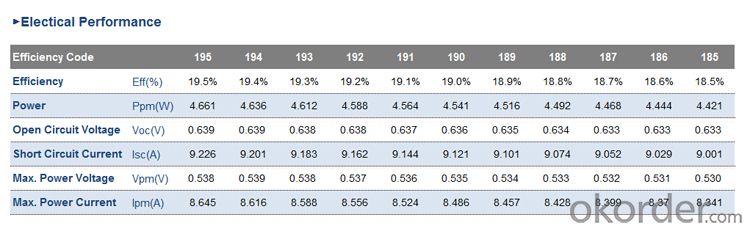

6. Specifications:

Dimension: 156mm x 156mm

Diagonal: 200mm (round chamfers)

Front: Anisotropically texturized surface and dark silicon nitride

anti-reflection coating

1.9mm silver bus bars

Back: Full-surface aluminum back-surface field

2.0mm (silver / aluminum) continuous soldering pads

Brief introduction of Monocrystalline Silicon Solar Cells

Monocrystalline silicon solar cells based on high-purity silicon rods as raw material for solar cells, is currently the fastest development of a solar cell. Its structure and the production process has been finalized, the products have been widely used in space and on the ground.

In order to reduce production costs, ground applications such as solar cells using solar grade silicon rods, materials performance has been relaxed. Some also use semiconductor device processing materials and discard the head and tail of silicon materials, solar cells drawn into complex dedicated silicon rods. The silicon rods cut into pieces, usually 0.3 mm thick sheet. After polishing, cleaning and other processes, the raw material will be made of silicon.

In the processing of making solar cells, the first doping and diffusion in silicon, a trace amount of dopant is generally boron, phosphorus, and antimony. Diffusion is carried out in a quartz tube into a high-temperature diffusion furnace. Thus formed P> N junction on the wafer. Then using a screen printing method, fine with a good paste into a grid line printed on the wafer, after sintering, while forming the back electrode and the surface coated with antireflection gate line source to prevent a large number of photons It is reflected off the smooth surface of the wafer.

Thus, the monomer monocrystalline silicon solar cells are produced. After single-chip random testing can be assembled according to the required specifications into a solar cell module (solar panel) by the method of series and parallel to a certain output voltage and current. Finally, package the frame and materials. According to user system design, solar cell components of various sizes square solar cells, also known as solar arrays. Photoelectric conversion efficiency of monocrystalline silicon solar cells are about 15%, the results of the laboratory also has reached more than 20%.

- Q: What is the impact of electromagnetic interference on solar cell performance?

- Electromagnetic interference can have a significant impact on solar cell performance. It can disrupt the normal operation of solar cells by introducing unwanted electrical signals that interfere with the proper functioning of the cells. This interference can lead to decreased efficiency and power output of the solar panels, as well as potential damage to the cells themselves. Therefore, it is crucial to minimize electromagnetic interference to ensure optimal performance and longevity of solar cells.

- Q: Can solar cells be used for electric vehicle charging?

- Yes, solar cells can be used for electric vehicle charging. Solar panels can convert sunlight into electricity, which can then be used to charge electric vehicles. This process, known as solar charging, provides a sustainable and renewable energy source for EVs, reducing their dependence on the grid and decreasing carbon emissions.

- Q: Can solar cells be used in military vehicles?

- Yes, solar cells can be used in military vehicles. They can provide an alternative source of energy to power various systems and equipment, reducing reliance on traditional fuel sources and enabling greater operational flexibility and sustainability. Additionally, solar cells can help extend the range and endurance of military vehicles in remote or austere environments where access to conventional fuel supplies may be limited.

- Q: Can I trust the suppliers for film solar that I found on alibaba ?

- From my own experience, I think they are pretty reliable because you can search all the information including the factory's address, product details, etc. all on the website.

- Q: Are there any subsidies or incentives for installing solar cells?

- Yes, there are various subsidies and incentives available for installing solar cells. These can include federal tax credits, state and local incentives, grants, and rebates. These measures aim to promote the adoption of solar energy and make it more affordable for individuals and businesses to invest in solar panel installations.

- Q: What is the role of surge suppressors in solar cell systems?

- The role of surge suppressors in solar cell systems is to protect the system from voltage spikes and surges caused by lightning strikes, power surges, or other electrical disturbances. These suppressors help in preventing damage to the solar panels, inverters, and other components of the system, ensuring their longevity and efficient operation.

- Q: How are solar cells different from solar panels?

- Solar cells are the basic building blocks of solar panels. While solar cells directly convert sunlight into electricity, solar panels are made up of multiple solar cells that are interconnected to generate a higher power output.

- Q: What is the typical warranty for solar cells?

- The typical warranty for solar cells varies, but it is commonly around 25 to 30 years for the performance warranty and 10 to 15 years for the product warranty.

- Q: What is the maximum efficiency of a solar cell?

- The maximum efficiency of a solar cell is determined by the Shockley-Queisser limit, which states that the theoretical maximum efficiency is around 33.7%. However, in practical applications, the highest efficiency achieved by commercially available solar cells is currently around 26-27%.

- Q: Can solar cells be used in airports?

- Yes, solar cells can be used in airports. They can be installed on rooftops, canopies, or other open spaces in airports to generate clean and renewable energy for various purposes such as lighting, power supply, and charging stations. Additionally, solar cells can contribute to reducing the carbon footprint and overall energy costs of airports.

Send your message to us

Longi High Energy Conversion Efficiency Monocrystalline Silicon Solar Cells with Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords