Wholesale Polycrystalline Solar Cells with High Efficiency and Stable Performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polycrystalline Silicon Solar Cells:

A solar cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Polycrystalline Silicon Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

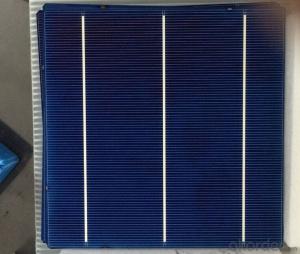

Specification:

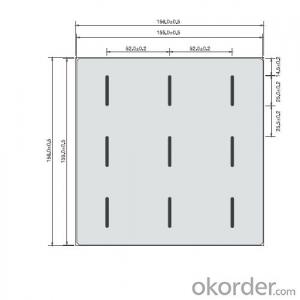

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

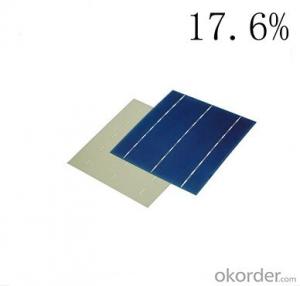

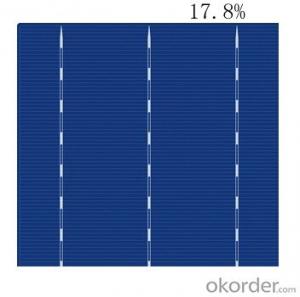

Electrical Characteristic |

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Voc (V) Isc (A) |

18.00% 4.380 0.538 8.141 0.634 8.740 |

17.90% 4.356 0.538 8.097 0.634 8.725 |

17.80% 4.331 0.537 8.065 0.633 8.710 |

17.70% 4.307 0.536 8.035 0.632 8.695 |

17.60% 4.283 0.535 8.006 0.631 8.680 |

17.50% 4.258 0.534 7.974 0.630 8.665 |

17.40% 4.234 0.533 7.944 0.629 8.650 |

17.30% 4.210 0.532 7.914 0.628 8.635 |

17.20% 4.185 0.531 7.88 -- 0.627 -- 8.620 |

17.10% 4.161 0.530 7.851 0.626 8.605 |

17.00% 4.137 0.529 7.820 0.625 8.590 |

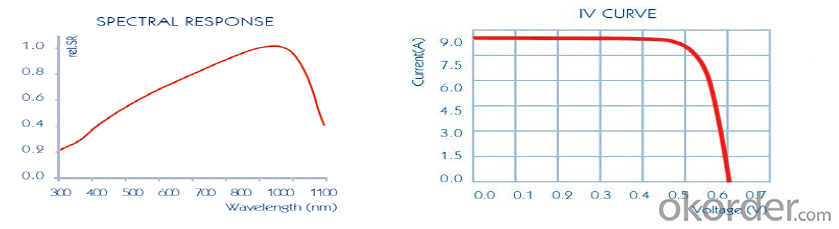

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

IV Curve

Usage of Polycrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Applications of Polycrystalline Solar Cells

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight, as distinguished from a "solar module" or "solar panel". A solar array generates solar power using solar energy.

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

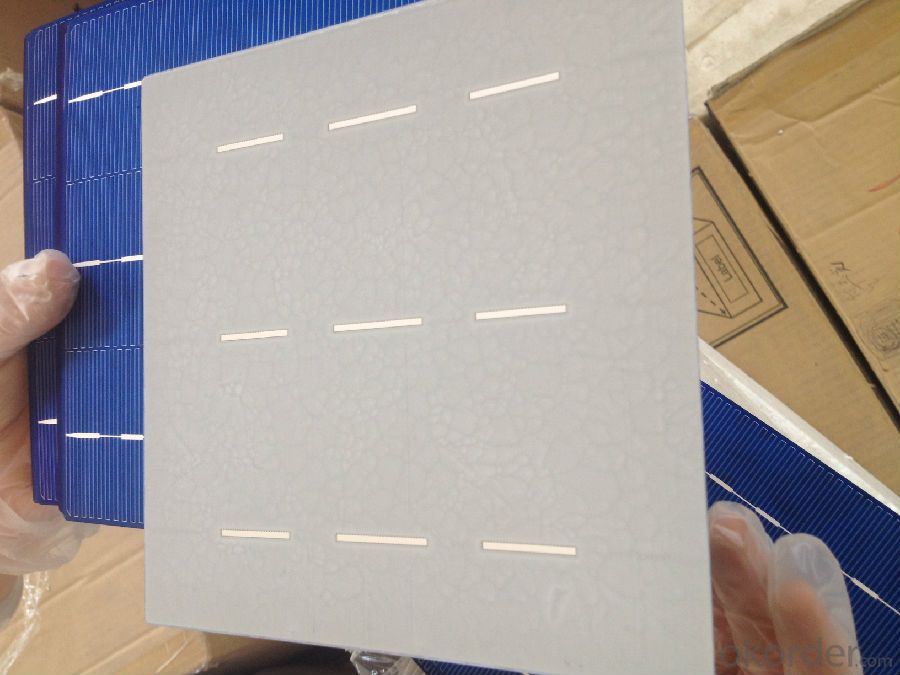

Solar Panel Images:

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

Brief introduction of High Current Solar Cell

The output voltage of the high current solar cell must be calibrated high-voltage battery voltage. When the battery is fully charged, the controller disconnects the charging circuit. When the battery voltage is lower than the set voltage value, the charging circuit will re-open. Solar cells are to use light, when the charging is straight.

Slotted solar cells reduce the positive coverage, while expanding the contact electrodes, greatly improving the current collection, and thus obtain higher conversion efficiency.

Slotted solar cells due to process at the current level of processing technology and processing techniques should be relatively simple terms, it is the most suitable for large-scale industrial production, BP Spain UNSW use of technology has produced nearly a hundred since 1992 MW BCSC batteries, the main problem is to solve the industrialization process route design, and strict quality control of the production process.

Among the many aspects to consider in order slotting process and metallization process is most important, not only to the quality of the battery and cell conversion efficiency, but also a very strong impact on industrial productivity. Slotting process a variety of styles, laser, mechanical grooving, chemical corrosion, physical groove, etc., which have a mature technology; we can meet the design requirements. In particular it should be noted that the groove is formed BC battery key, groove, physical dimensions and surface state will very strongly affect battery performance parameters, in addition to metalization BC battery is a very important part, should arouse a high degree of seriously.

BCSC for monocrystalline silicon single-crystal silicon, should use high quality Cz silicon, should try to reduce the oxygen, and carbon content of heavy metal impurities, special emphasis is to select few defects, in order to ensure a higher wafer carrier lifetime.

- Q: What is the maximum efficiency achievable by a solar cell?

- The maximum efficiency achievable by a solar cell is determined by the Shockley-Queisser limit, which states that the theoretical maximum efficiency is around 33.7%. However, in practice, most commercially available solar cells have efficiencies ranging between 15% to 22%.

- Q: What is the role of combiners in solar cell systems?

- The role of combiners in solar cell systems is to combine the electrical outputs from multiple solar panels into a single circuit, allowing for more efficient utilization of the generated power.

- Q: Can solar cells be used in camping or outdoor recreational activities?

- Yes, solar cells can be used in camping or outdoor recreational activities. They are a convenient and environmentally friendly way to generate electricity in remote locations where power outlets may not be available. Solar panels can be used to charge portable devices such as phones, laptops, or camping lights, providing a sustainable source of energy while enjoying outdoor activities.

- Q: How big are solar cells?

- Solar cells vary in size depending on their intended use and technology. Traditional silicon-based solar cells typically range in size from a few square centimeters to around 200 square centimeters. However, advancements in solar technology have led to the development of smaller, more efficient solar cells, known as thin-film solar cells, which can be as small as a few square millimeters. Additionally, solar cells can be grouped together to form larger arrays, which are commonly used in residential, commercial, and utility-scale solar installations.

- Q: Friends are fuel cells are chemical energy into electricity, solar cells are converted into electricity into electricity I would like to know in addition to the structure and the conversion of different ways there are no other differences hope that the specific power of everyone

- In general, the fuel cell has the following characteristics: (1) high energy conversion efficiency He will directly convert the chemical energy of fuel into electricity, the middle without the combustion process, and thus not limited by the Carnot cycle.

- Q: Is that true that the price of solar cells will be reduced in the coming year?

- It is very possibile that that solar cells' price will go down this year because there were many orders last year, either from European or China market. The solar cells are actually very sustainable. Once you buy it, you can use it for years. With the falling demand the price of course will go down.

- Q: Which Solar Panel Type is best? Polycrystalline panel or PV Module Monocrystalline Solar cell panel, or thin film?

- Monocrystalline solar panels live the longest. Most solar panel manufacturers put a 25-year warranty on their monocrystalline solar panels.

- Q: What is the maximum efficiency of a solar cell?

- The maximum efficiency of a solar cell is determined by the Shockley-Queisser limit, which states that the theoretical maximum efficiency is around 33.7%. However, in practical applications, the highest efficiency achieved by commercially available solar cells is currently around 26-27%.

- Q: Is the solar cells factory in China good and trustworthy?

- 5 years ago, I vistied a solar cell factory based in Inner Mongolia, and I was quite impressed by their professionalism, which gave me more confidence that they are better than we thought.

- Q: Can solar cells be used in power plants?

- Yes, solar cells can be used in power plants. Solar power plants, also known as solar farms or solar parks, use large arrays of solar panels or solar cells to convert sunlight into electricity on a larger scale. These power plants capture and harness solar energy to generate electricity, making them a sustainable and renewable energy source.

Send your message to us

Wholesale Polycrystalline Solar Cells with High Efficiency and Stable Performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords