Polycrystalline Solar Cells 2BB/3BB with Long-term Electrical Stability

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4200 watt

- Supply Capability:

- 600000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

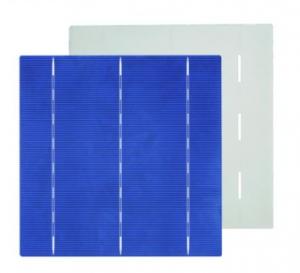

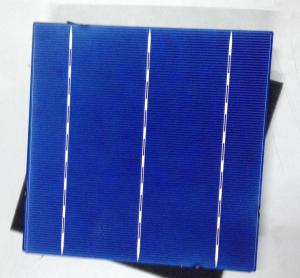

Specifications of Poly Solar Cells

Format | 156 mm × 156 mm ± 0.5 mm |

Thickness- | 210μm ± 40 μm |

Front (-) | 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) | 2.5mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Poly Cells

Voc.Temp .coef.%/K | -0.351%/K |

| Isc.Temp .coef.%/K | +0.035%/K |

| Pm.Temp. coef.%/K | -0.47%/K |

Electrical Characteristic of Poly Cells

Efficiency | Efficiency | Pmax(W) | Average | Impp(A) | Vmpp(V) | Isc(A) | Voc(V) |

1720 | 17.20~17.40 | > 4.186 | > 4.186 | 7.94 | 0.528 | 8.515 | 0.626 |

1700 | 17.00~17.20 | 4.137~4.186 | 4.161 | 7.905 | 0.525 | 8.482 | 0.624 |

1680 | 16.80~17.00 | 4.088~4.137 | 4.113 | 7.863 | 0.521 | 8.402 | 0.623 |

1660 | 16.60~16.80 | 4.040~4.088 | 4.064 | 7.825 | 0.519 | 8.358 | 0.622 |

1640 | 16.40~16.60 | 3.991~4.040 | 4.015 | 7.769 | 0.517 | 8.304 | 0.621 |

1620 | 16.20~16.40 | 3.942~3.991 | 3.967 | 7.713 | 0.514 | 8.248 | 0.619 |

1600 | 16.00~16.20 | 3.894~3.942 | 3.918 | 7.67 | 0.511 | 8.204 | 0.616 |

Advantages of Poly Solar Cells

1. High efficiency and High power.

2. Long-term electrical stability.

3. Lowest price and Fastest delivery.

4. Good quality and good service.

5. Bulk supply

6. Good Warranty

7. Big Sale

8. More than 25 years on the lifetime.

Usage and Applications of Poly Cells

Solar cells are often electrically connected and encapsulated as a module.

Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage.

Connecting cells in parallel will yield a higher current;our solar cells have passed IEC Certification.

With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Packaging & Delivery of Poly Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid water, sunshine and moist.

Factory Picture of Poly Cells

Package Picture of Poly Cells

Polycrystalline solar cells 2BB/3BB combines the high conversion efficiency monocrystalline silicon cells and preparation of amorphous silicon thin film materials as well as long-life battery, etc. relatively simplified new generation of batteries, the conversion efficiency is generally about 12%, slightly lower than the silicon solar cells, there is no obvious efficiency recession, and may be prepared on an inexpensive substrate material, the cost is much lower than silicon cells, and more efficient than amorphous silicon thin film batteries.

From the production cost, than monocrystalline silicon solar cells cheaper, simple materials, saving power consumption, lower overall production costs, and therefore get a lot of development. In addition, Polycrystalline solar cells 2BB/3BB battery life is also shorter than the single crystal silicon solar cells.

Monocrystalline silicon solar cell production requires large amounts of high-purity silicon material and manufacturing process complexity of these materials, power consumption is large, the total production cost of solar cells has over one-half. Coupled with cylindrical silicon rods drawn, sliced wafer production of solar cell is composed of low solar plane component. Therefore, since the 1980s, some European and American developed countries put Polycrystalline solar cells 2BB/3BB.

Has been the focus of a single crystal to polycrystalline direction, mainly due to; [1] can supply less and less solar cell material end to end; [2] in terms of solar cell, a square substrate is more cost-effective, and by casting method polysilicon direct solidification method can be directly obtained rectangular materials; the production process [3] polysilicon continue to make progress, automatic casting furnace each production cycle (50 hours) can produce over 200 kg ingots, grain size reaches cm level; [4] Since the last decade of research and development of single-crystal silicon technology quickly, which technology has also been applied to the production of polycrystalline silicon cells, such as selective etching the emitter, back surface field, corrosion suede, surface and bulk passivation , thin metal gate electrode, using screen printing technology allows the width of the gate electrode is reduced to 50 m, height of 15 m or more, rapid thermal annealing technology for polysilicon production process can significantly shorten the time, single-chip thermal process time can be less than a minute to complete, using the technology in the 100 cm2 polycrystalline silicon sheet made cell conversion efficiency over 14%. According to reports, the 50 to 60 micron substrate made of polysilicon cell efficiency of over 16%. The use of mechanical groove, screen printing technology in 100 square centimeters crystal efficiency more than 17%, no mechanical groove in the same area on the efficiency of 16%, using buried gate structure, mechanical groove in the 130 cm2 polycrystalline on the cell efficiency reached 15.8%.

- Q: Can solar cells be used to power wireless communication networks?

- Yes, solar cells can be used to power wireless communication networks. Solar cells are capable of converting sunlight into electricity, which can be stored in batteries or directly used to power various devices, including wireless communication equipment. This renewable energy source offers a sustainable and environmentally friendly solution for powering wireless networks in remote or off-grid locations. Additionally, advancements in solar cell technology have made them more efficient and cost-effective, making them a viable option for powering these networks.

- Q: What is the average lifespan of a solar cell?

- The average lifespan of a solar cell is typically around 25 to 30 years.

- Q: What factors affect the efficiency of solar cells?

- Several factors can affect the efficiency of solar cells. The first is the quality and type of materials used in the cell's construction. High-quality and advanced materials tend to have higher conversion efficiencies. The second factor is the amount and intensity of sunlight received by the solar cell. More sunlight and higher intensity can increase the energy output. Additionally, the temperature of the cell also plays a role, as high temperatures can reduce efficiency. Finally, the design and structure of the solar cell, including the arrangement of layers and the surface area, can impact its efficiency.

- Q: How do solar cells perform in areas with high humidity?

- Solar cells typically perform slightly less efficiently in areas with high humidity due to the presence of moisture in the air. The water vapor can reduce the amount of sunlight reaching the solar cells and can also cause corrosion over time. However, modern solar cell designs have improved significantly to mitigate these effects and ensure reliable performance even in humid conditions.

- Q: How do solar cells perform in areas with frequent thunderstorms?

- Solar cells can still operate effectively in areas with frequent thunderstorms. While thunderstorms can temporarily decrease solar cell performance due to reduced sunlight exposure, advancements in solar technology have made solar cells more durable and resistant to extreme weather conditions. Additionally, solar cells can still generate electricity from diffused sunlight during cloudy or stormy days. Overall, solar cells can still be a viable and sustainable energy option in areas with frequent thunderstorms.

- Q: Can solar cells be used for powering telecommunications towers?

- Yes, solar cells can be used for powering telecommunications towers. Solar panels can generate electricity by converting sunlight into usable energy, which can then be used to power various devices and infrastructure, including telecommunications towers. This renewable energy source provides a sustainable and environmentally friendly solution for powering such towers, especially in remote or off-grid areas.

- Q: How big are solar cells?

- Solar cells vary in size depending on their application. They can range from small cells measuring a few centimeters in width and length, commonly used in portable electronics, to larger panels that can be several meters in width and length, used in residential or commercial installations.

- Q: Do you believe you can make a solar cell by using kitchenware?

- You must be joking.

- Q: Can solar cells be used in agriculture?

- Yes, solar cells can be used in agriculture. They can be used to power various equipment and systems in farming, such as irrigation systems, ventilation systems, and lighting for greenhouses. Solar energy can also be utilized to charge batteries for electric farm vehicles and tools, reducing reliance on fossil fuels and minimizing carbon emissions. Additionally, solar panels can be mounted on rooftops or installed as shade structures to provide shelter for livestock while generating clean energy.

- Q: Can solar cells be used for powering electric vehicles in motion?

- Yes, solar cells can be used to power electric vehicles in motion. Solar panels can be installed on the roof or body of the vehicle to capture sunlight and convert it into electricity, which can then be used to power the vehicle's electric motor. While the amount of power generated by solar cells may not be sufficient to completely run the vehicle, it can supplement the battery's charge and increase the overall range of the electric vehicle.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 320 Million |

| Main Markets | Australia; Asia; South East Asia; South America; North America; Europe; Africa |

| Company Certifications | ISO 9001:2008; CE; TUV; UL |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo, China |

| Export Percentage | 45% - 50% |

| No.of Employees in Trade Department | 200-300 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 Square meter |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Polycrystalline Solar Cells 2BB/3BB with Long-term Electrical Stability

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4200 watt

- Supply Capability:

- 600000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords