2016 Hot Sale Mono Solar Cells 2BB/3BB 156 mm X 156 mm Products

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4200 watt

- Supply Capability:

- 600000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

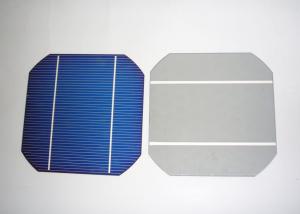

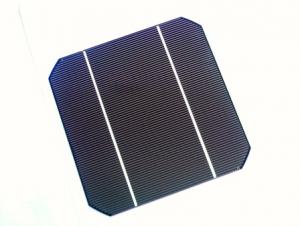

Specifications of Mono Solar Cells

Format : 156 mm × 156 mm ± 0.5 mm

Thickness: 210 μm ±40 μm

Front (-) : 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

Back (+) : 2.5mm wide soldering pads (silver) back surface field (aluminium)

Electrical Characteristic of Mono Solar Cells

Efficiency (%) | Pmpp (W) | Umpp (V) | Impp (A) | Uoc (V) | Isc (A) | FF (%) |

18.35 | 4.384 | 0.526 | 8.333 | 0.63 | 8.877 | 78.39% |

18.20 | 4.349 | 0.526 | 8.263 | 0.63 | 8.789 | 78.54% |

18.05 | 4.313 | 0.525 | 8.216 | 0.63 | 8.741 | 78.32% |

17.90 | 4.277 | 0.524 | 8.161 | 0.629 | 8.713 | 78.04% |

17.75 | 4.241 | 0.523 | 8.116 | 0.629 | 8.678 | 77.70% |

17.60 | 4.206 | 0.521 | 8.073 | 0.628 | 8.657 | 77.36% |

17.45 | 4.170 | 0.519 | 8.039 | 0.628 | 8.633 | 76.92% |

17.30 | 4.134 | 0.517 | 8.004 | 0.626 | 8.622 | 76.59% |

17.15 | 4.098 | 0.516 | 7.938 | 0.625 | 8.537 | 76.80% |

17.00 | 4.062 | 0.512 | 7.933 | 0.625 | 8.531 | 76.18% |

16.75 | 4.002 | 0.511 | 7.828 | 0.625 | 8.499 | 75.34% |

16.50 | 3.943 | 0.510 | 7.731 | 0.625 | 8.484 | 74.36% |

Advantage of Mono Solar Cells

1. High efficiency and High power.

2. Long-term electrical stability.

3. Lowest price and Fastest delivery.

4. Good quality and best service.

5. Bulk supply

6. Trusted Warranty

7. Big Sale

8. More than 25 years on the lifetime.

Usage and Applications of Mono Solar Cells

Solar cells are often electrically connected and encapsulated as a module.

Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc.

Solar cells are also usually connected in series in modules, creating an additive voltage.

Connecting cells in parallel will yield a higher current;our solar cells have passed IEC Certification. With high quality and stable quality.

Our Cells can greatly improve the performance of Solar Modules.

Packaging & Delivery of Mono Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Factory Picture of Mono Solar Cells

Package Picture of Mono Solar Cells

In the long term, despite the current cost of a single crystal is high, but the cost of the single crystal pulling and other non-silicon costs will gradually close to the ingot and other non-cost polycrystalline silicon in future, therefore the downside of mono solar cells’ cost is greater than polycrystalline. At the same time the existing P-type cell conversion efficiency has been gradually facing a bottleneck, while the new N-type monocrystalline cells (conversion efficiency to 22% to 24%) is already in production, costs and wait until the technology to further breakthroughs, is expected to gradually spread. So the future is expected to gradually increase the amount of a single crystal production, the production of photovoltaic silicon cells account for world dominance.

Polycrystalline silicon solar cell production analysis

According to statistics, 2003--2012 global polysilicon solar cell production increased year by year, from 2003 to 2012 grew 467MW 17292MW, the annual compound growth rate of more than 40% from the market share of various types of solar cells see 2003 - 2005 period the proportion of polycrystalline silicon cells decreased from 63-57% in 2006 - in 2012 it remained stable at 45% - 50%. The first half of 2013, global polysilicon solar cell production reached 9432MW.

Polycrystalline silicon solar cell market outlook

The first half of 2013, global polysilicon production reached 100,000 tons, crystalline silicon solar cell production of 18GW, polycrystalline silicon consumes about 11 million tons, because the downstream PV companies continue to digest inventory, the polysilicon market supply and demand balance. From a market share point of view, 2012 - May 2013, the market share is still slightly higher than the polycrystalline silicon solar cell silicon solar cells. This highlights the current status of polycrystalline silicon photovoltaic cell technology market is still one of the two major technology firms.

But according to the performance of domestic companies since 2012, mono solar cells 2BB/3BB technology is better than the overall performance of the company polysilicon companies. The current global PV market has not yet fully grown; mono solar cells 2BB/3BB and polycrystalline technology has living space. Short and medium term, polysilicon will remain relatively dominant. From the long-term trend, mono solar cells 2BB/3BB will be able to share half of the market space at least.

- Q: How do solar cells perform in areas with high levels of air pollutants?

- Solar cells may experience a decrease in performance in areas with high levels of air pollutants due to reduced sunlight reaching the surface. The presence of pollutants such as smog and particulate matter can block and scatter sunlight, thereby reducing the efficiency of solar cells. Regular cleaning and maintenance of solar panels can help mitigate the impact of air pollutants and ensure optimal performance.

- Q: Can solar cells be used to power emergency lighting systems?

- Yes, solar cells can be used to power emergency lighting systems. Solar cells convert sunlight into electricity, which can be stored in batteries for later use. This makes them a reliable and sustainable source of power for emergency lighting, ensuring that they will continue to function even during power outages or other emergencies.

- Q: Can solar cells be used in air conditioning systems?

- Yes, solar cells can be used in air conditioning systems. Solar-powered air conditioning systems utilize solar panels to generate electricity which is then used to power the air conditioning unit. This allows for a more sustainable and environmentally friendly cooling solution.

- Q: Can anybody tell me the power supply of the home solar cell?

- Since the power supply of two solar cells panel would be below 500 watts, so if you are not using too much euipment at home at one time, you won't be needing more than 250WATTS

- Q: What is the impact of saltwater exposure on solar cell efficiency?

- Saltwater exposure can have a significant negative impact on solar cell efficiency. The saltwater can corrode the metal components of the solar cells, leading to a decrease in their performance and overall efficiency. Additionally, the saltwater can create a conductive pathway that can bypass the solar cells, resulting in a loss of electrical energy. Therefore, it is crucial to protect solar cells from saltwater exposure to maintain their efficiency and prolong their lifespan.

- Q: What is the impact of solar cells on reducing dependence on foreign energy sources?

- Solar cells have a significant impact on reducing dependence on foreign energy sources by providing a renewable and locally available source of electricity. By harnessing the power of the sun, solar cells offer a clean and sustainable alternative to fossil fuels, which often need to be imported from other countries. This shift towards solar energy not only enhances energy security but also reduces reliance on foreign nations for energy supply, thus promoting self-sufficiency and reducing geopolitical risks associated with energy imports.

- Q: Can solar cells be used in disaster response vehicles?

- Yes, solar cells can be used in disaster response vehicles. They can help power the vehicle's electrical systems and equipment, providing a sustainable and reliable source of energy in emergency situations where traditional power sources may be unavailable or unreliable. Additionally, solar cells can reduce the dependence on fossil fuels and contribute to a more environmentally friendly response effort.

- Q: Can solar cells be used in urban areas?

- Yes, solar cells can be used in urban areas. In fact, they are increasingly being used in cities worldwide as a renewable energy solution. With the advancement of technology, solar cells can be installed on rooftops, facades, and even integrated into urban infrastructure like streetlights and bus shelters. This allows urban areas to harness clean energy from the sun and reduce their dependence on fossil fuels, contributing to a more sustainable and environmentally friendly future.

- Q: Can solar cells be used in extreme climates?

- Yes, solar cells can be used in extreme climates. While extreme temperatures and harsh weather conditions can affect their efficiency to some extent, solar cells are designed to withstand a wide range of climates. In fact, many solar installations are successfully operating in extreme environments such as deserts, polar regions, and high-altitude areas. Proper design, installation, and maintenance techniques can ensure their optimal performance and durability even in challenging climate conditions.

- Q: How do solar cells impact energy consumption patterns?

- Solar cells impact energy consumption patterns by providing a renewable and clean source of electricity. They reduce reliance on traditional fossil fuels, decrease greenhouse gas emissions, and promote sustainable energy practices. Solar cells enable individuals, businesses, and communities to generate their own power, leading to a more decentralized and resilient energy system. Additionally, solar energy contributes to a more balanced and diversified energy mix, reducing the strain on conventional power grids and enhancing energy security.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 320 Million |

| Main Markets | Australia; Asia; South East Asia; South America; North America; Europe; Africa |

| Company Certifications | ISO 9001:2008; CE; TUV; UL |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo, China |

| Export Percentage | 45% - 50% |

| No.of Employees in Trade Department | 200-300 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 Square meter |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

2016 Hot Sale Mono Solar Cells 2BB/3BB 156 mm X 156 mm Products

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4200 watt

- Supply Capability:

- 600000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords