Cheap Solar Cells for Sale - Polycrystalline Solar Cells Tyre 1 Manufacturer Effy 16.4%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 50000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Solar Cells

A solar cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

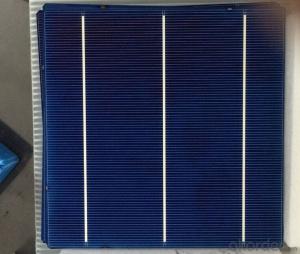

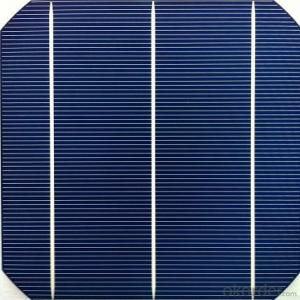

Specifications of Polycrystalline Solar Cells

Format : 156 mm × 156 mm ± 0.5 mm

Thickness: 210 μm ±40 μm

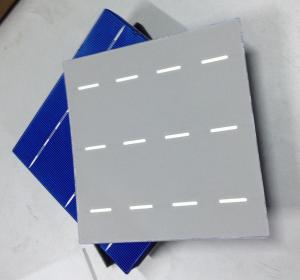

Front (-) : 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

Back (+) : 2.5mm wide soldering pads (silver) back surface field (aluminium)

Efficiency (%) | Pmpp (W) | Umpp (V) | Impp (A) | Voc (V) | Isc (A) |

18.00% | 4.38 | 0.528 | 8.291 | 0.631 | 8.869 |

17.80% | 4.33 | 0.525 | 8.252 | 0.629 | 8.821 |

17.60% | 4.29 | 0.532 | 8.053 | 0.633 | 8.541 |

17.40% | 4.23 | 0.528 | 8.092 | 0.624 | 8.632 |

17.20% | 4.19 | 0.524 | 7.992 | 0.62 | 8.458 |

17.00% | 4.14 | 0.52 | 7.972 | 0.623 | 8.5 |

Advantage of Polycrystalline Solar Cells

1. Tire-1 Solar Cells’ Manufacturer Quality Guarantee. With a complete and sophisticated quality government system, our Quality Management have arrived world’s leading place. Customer can receive Tire-1 Cells Maker’s Quality Standard Products.

2. Trusted Warranty. We supply good after-sales to our customers. Any defects which is not comply with our quality standard, can be claimed by our customers.

3. World wide market: Now we have explored wide customer group over the world. Now we have customers in Asia, like India, Philippines, Thailand, Japan. Europe like German, UK, France, Italy etc. And also North and South America are also important area.

4. Stable Supply of Solar Cells. With the capacity of 500MW, we can supply a stable quantity to the world.

Usage of Polycrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Applications of Polycrystalline Solar Cells

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight, as distinguished from a "solar module" or "solar panel". A solar array generates solar power using solar energy.

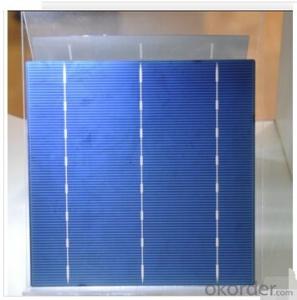

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Factory Picture of Solar Cells

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2. Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3. How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4. Can you do OEM for us?

Yes, we can.

5. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What is a monocrystalline solar cell?

- A monocrystalline solar cell is a type of solar panel that is made from a single crystal structure, typically silicon. It is known for its high efficiency and sleek, black appearance. The single crystal structure allows for better electron flow, resulting in greater energy conversion from sunlight into electricity.

- Q: Can solar cells be used to power emergency lighting systems?

- Yes, solar cells can be used to power emergency lighting systems. Solar cells convert sunlight into electricity, which can be stored in batteries for later use. In the event of a power outage, these solar-powered batteries can provide a reliable source of energy to power emergency lighting systems, ensuring safety and visibility during emergencies.

- Q: Can solar cells be used on satellites?

- Yes, solar cells can be and are commonly used on satellites as their primary source of power. Solar cells convert sunlight into electricity, providing a reliable and renewable source of energy for satellites in orbit around the Earth.

- Q: Where can I get a competitive price for this solar cell? The 2bb/3bb polycrystalline solar cell panel?

- You can try this website, alibaba to find what you need, because I purchased the 2bb/3bb polycrystalline solar cell panel on that website last year.

- Q: How do solar cells perform in different temperature ranges?

- Solar cells generally perform less efficiently at high temperatures. This is because the increase in temperature can lead to an increase in electron-hole recombination, reducing the overall photoelectric conversion efficiency. On the other hand, solar cells can also experience a decrease in performance at extremely low temperatures, although this effect is usually less significant. Overall, the efficiency of solar cells varies with temperature, with a decline at high temperatures and a smaller impact at low temperatures.

- Q: How do solar cells handle power quality issues?

- Solar cells do not directly handle power quality issues. However, inverters are used in solar power systems to convert the direct current (DC) generated by solar cells into alternating current (AC) that can be used in homes and businesses. These inverters often have built-in features to address power quality issues such as voltage fluctuations, harmonic distortions, and frequency variations. Additionally, grid-tied solar systems can rely on the electrical grid itself to handle power quality issues, as any excess power generated by solar cells can be fed back into the grid, ensuring a stable and reliable power supply.

- Q: Can solar cells be used in disaster response vehicles?

- Yes, solar cells can be used in disaster response vehicles. They can help power the vehicle's electrical systems and equipment, providing a sustainable and reliable source of energy in emergency situations where traditional power sources may be unavailable or unreliable. Additionally, solar cells can reduce the dependence on fossil fuels and contribute to a more environmentally friendly response effort.

- Q: How can I calculate the cost of using solar cells if I put a fully-functional solar system in my house?

- Sunrun solar lets you get started for as little as $0 down, but to install it, it will cost you a lot.

- Q: What is the lifespan of a solar cell battery?

- The lifespan of a solar cell battery can vary depending on various factors such as the quality of the battery, usage patterns, and maintenance. On average, a well-maintained solar cell battery can last anywhere between 5 to 20 years.

- Q: Can solar cells be used for powering outdoor signage?

- Yes, solar cells can be used for powering outdoor signage. Solar cells convert sunlight into electricity, which can be stored and used to power various devices, including outdoor signage. This allows the signage to operate independently of the electrical grid, making it a cost-effective and environmentally-friendly solution.

Send your message to us

Cheap Solar Cells for Sale - Polycrystalline Solar Cells Tyre 1 Manufacturer Effy 16.4%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 50000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords