modern steel structure sculpture projects

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

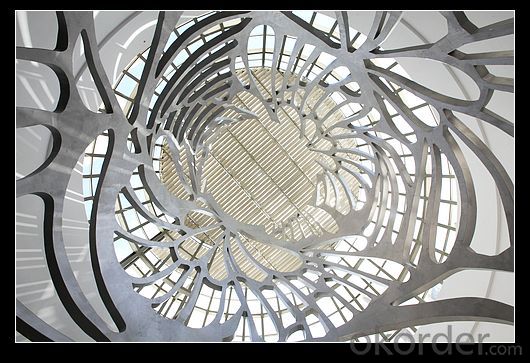

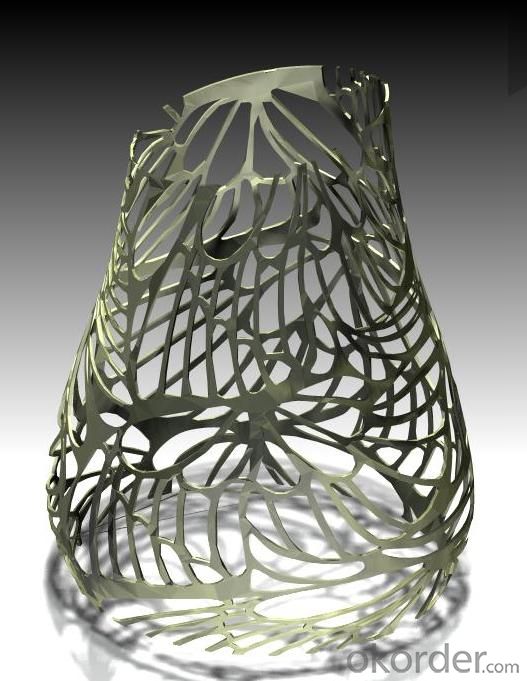

Modern steel structure sculpture projects

Guangdong sunrise steel structure company ,which was established in 2007, covers an area of 30000 M2, is a modern enterprise specialized in processing and manufacturing various kinds of steel structures buildings over 300. Such as : steel canopy, steel spiral staircase and steel art sculpture,steel container house. steel warehouse.

We have 100 unites equipment for large and medium-sized metal processing, welding, assembly process

In 2013, Sunrise cooperated with MGM Group to create a giant metal Butterfly engraving, which is sitting in the lobby of MGM Grand Sanya. It’s 22 meters tall, the maximum diameter is15.5 meters, coordinates of the points to reach 5500. Sunrise completed all works and fulfilled the goal as planned after overcoming many difficulties. Fully demonstrated sunrise has a strong strength in art landscape steel structure.

Packing: As per customer's requirement by bulk or removable storage rack

Lead time:25 days to 30 days after signed the contract.

FAQ:

Does your company is a factory or trade company?

We are factory, so you will enjoy the best price and competitive price.

What’s the quality assurance you provided and how do you control quality ?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc.

Can you offer designing Prefabricated Steel Warehouse service?

Yes, we have more than 30 design engineers. We could design full solution drawings as per your requirments. They use software: Auto CAD,PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc.

Do you offer guiding installation on site overseas for Prefabricated Steel Warehosue ?

Yes, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineer to surpervise installation on site overseas. They have succeeded in many countries, such as Iraq, Dubai, South Africa, Algerial, Ghana

- Q: What are the design considerations for steel pedestrian bridges?

- Some key design considerations for steel pedestrian bridges include structural integrity, durability, aesthetic appeal, accessibility, and safety. The bridge must be able to support the weight of pedestrians and withstand external forces such as wind and seismic activity. It should also be resistant to corrosion and have a long lifespan. Aesthetically, it should blend well with the surrounding environment and contribute to the overall visual appeal. Accessibility is crucial, requiring consideration of ramps, stairs, and elevators to ensure ease of use for people with disabilities. Lastly, safety measures such as handrails, non-slip surfaces, and proper lighting should be incorporated to ensure the well-being of pedestrians.

- Q: What is the purpose of steel beams in structures?

- Steel beams serve the purpose of providing structural support and stability in various structures. With their strength and durability, they are capable of withstanding heavy loads and resisting bending or buckling when subjected to pressure. They find common usage in the construction of buildings, bridges, and other large structures to evenly distribute weight and prevent collapse. Moreover, steel beams enable the creation of open and flexible floor plans as they can span long distances without the necessity of additional support columns. Furthermore, steel beams possess fire resistance, rendering them suitable for structures that require enhanced safety measures. Ultimately, the aim of steel beams is to guarantee the integrity and longevity of a structure by establishing a solid and dependable framework.

- Q: What are the factors to consider when designing steel structures for architectural aesthetics?

- When designing steel structures for architectural aesthetics, several factors need to be considered. First and foremost is the overall visual appeal of the structure, taking into account the desired style, form, and visual impact. Additionally, the material properties of steel, such as its strength, durability, and flexibility, should be considered to ensure that the structure can meet both aesthetic and functional requirements. The choice of finishes, such as paint, coatings, or even exposed weathering steel, can greatly impact the appearance of the structure. Attention must also be paid to the integration of steel elements with other architectural materials and components, ensuring a cohesive design. Lastly, the cost and practicality of constructing and maintaining the steel structure should be taken into account to ensure that the desired aesthetics can be achieved within budget and with feasible construction techniques.

- Q: What are the primary factors influencing the selection of steel grades for structural applications?

- The selection of steel grades for structural applications is influenced by several primary factors. Firstly, the strength and durability requirements of the structure play a crucial role in determining the suitable steel grade. Different grades of steel possess varying strength characteristics, such as yield strength and ultimate tensile strength, which determine their ability to withstand loads and resist deformation. Secondly, the environmental conditions in which the structure will be placed are important considerations. Factors such as temperature variations, exposure to moisture or corrosive substances, and seismic activities can impact the performance and longevity of the steel. Therefore, steel grades with specific properties, such as corrosion resistance or high-temperature strength, may be preferred depending on the environmental conditions. Another key factor is cost-effectiveness. The availability and cost of different steel grades can influence their selection. Some high-strength steel grades may be more expensive, but their utilization can lead to material savings and reduced weight of the structure, resulting in economic benefits in terms of construction and maintenance costs. Furthermore, the fabrication and installation processes also play a role in grade selection. Certain steel grades may require specific welding techniques or heat treatment processes, which can impact the ease of fabrication and the associated costs. The availability of skilled labor and suitable equipment for working with specific steel grades also needs to be considered. Lastly, industry standards, codes, and regulations are essential factors in selecting steel grades for structural applications. Compliance with these standards ensures the safety and reliability of the structure. Steel grades that meet the required specifications and have been tested and certified for structural applications are preferred to ensure compliance with regulatory requirements. In conclusion, the primary factors influencing the selection of steel grades for structural applications include strength and durability requirements, environmental conditions, cost-effectiveness, fabrication and installation considerations, and adherence to industry standards and regulations. Each of these factors must be carefully evaluated to determine the most suitable steel grade for a given structural application.

- Q: How are steel structures used in the construction of concert venues?

- Steel structures are commonly used in the construction of concert venues due to their durability, strength, and versatility. Steel beams and columns provide the necessary framework to support large roof spans and heavy equipment, such as lighting rigs and sound systems. They can also be designed to withstand dynamic loads and vibrations generated by the audience and performers. Additionally, steel allows for creative architectural designs, enabling the construction of unique and visually appealing concert venues.

- Q: What does "BH beam" mean in steel structure?

- In steel structure, the reinforcement ratio of BH beam is B, which is the width of rectangular section; H (0) is the effective height of cross section.

- Q: How are steel structures used in the construction of cinemas?

- Due to their strength, durability, and versatility, steel structures are commonly employed in the construction of cinemas. Steel proves to be an excellent material for constructing spacious cinema auditoriums, as it can handle heavy loads and span long distances without the need for obstructive columns or supports that might impede the view of the screen. The cinema building's skeleton is often formed using steel frames, which create a robust and stable structure capable of withstanding external forces like wind and earthquakes. The steel beams and columns are meticulously designed and engineered to ensure that the roof, walls, and other components can be safely supported. Not only is steel utilized in the main structure, but it also finds its way into various other cinema elements. For instance, steel is frequently employed in the framing of cinema screens, providing a rigid and stable surface for movie projection. Additionally, steel is used in constructing staircases, balconies, handrails, and other architectural features within the cinema. Furthermore, steel is an environmentally friendly and sustainable choice for cinema construction. As a recyclable material, steel aids in reducing the building's overall carbon footprint. Moreover, steel structures can be prefabricated off-site, thereby reducing construction time and minimizing disruption to the surrounding area. In conclusion, the construction of cinemas heavily relies on steel structures, which provide a sturdy, long-lasting, and adaptable framework that can cater to the unique requirements of these entertainment venues.

- Q: What are the guidelines for the maintenance and inspection of steel structures?

- The guidelines for the maintenance and inspection of steel structures typically include regular visual inspections to identify any signs of corrosion, cracking, or other structural issues. It is important to follow manufacturer recommendations for cleaning and maintenance, including regular washing and removal of any debris that can contribute to corrosion. Additionally, periodic structural inspections by certified professionals are crucial to ensure the integrity and safety of the steel structure. Regular maintenance and inspections help to identify and address any potential issues early on, preventing costly repairs or structural failures.

- Q: How do steel structures perform in high winds?

- High winds are generally handled well by steel structures. Steel possesses high strength and rigidity, making it an ideal material for enduring strong winds and extreme weather. The inherent properties of steel, such as its high tensile strength and ductility, enable it to effectively resist the forces exerted by wind loads. To evenly distribute wind loads throughout the structure, steel structures are designed with inherent stability. This is achieved through appropriate bracing and cross-sectional shapes that effectively dissipate wind forces. Optimal performance is ensured by considering factors like wind direction, wind speed, and the specific location of the structure during the design process. Flexibility is often incorporated into steel buildings, allowing them to absorb and dissipate the energy generated by high winds. The ability to flex and deform under wind loads minimizes the risk of structural damage or failure. Additionally, the low weight-to-strength ratio of steel structures reduces wind pressure. Furthermore, steel structures can be further improved for high wind performance by incorporating additional features like aerodynamic shapes, wind deflectors, and streamlined designs. These measures reduce wind turbulence and prevent the formation of vortices, which can increase the wind forces acting on the structure. In conclusion, steel structures have a proven track record of performing well in high winds. Their stability, strength, and flexibility make them a reliable choice for areas prone to strong winds or extreme weather conditions. However, it is crucial to ensure that professionals design and construct the steel structure following the necessary codes and standards to guarantee its safety and performance in high winds.

- Q: How do steel structures withstand extreme weather conditions?

- The inherent properties of steel as a construction material enable steel structures to withstand extreme weather conditions. Steel's strength and durability make it highly resistant to severe weather phenomena like high winds, heavy snow, and earthquakes. Efficient load distribution and transfer are key factors in the ability of steel structures to withstand extreme weather conditions. Steel's high strength-to-weight ratio allows it to support heavy loads without excessive weight, allowing for optimal load distribution and preventing stress points that could lead to failure. In addition, steel's resistance to corrosion is crucial for withstanding weather conditions such as humidity, rain, and saltwater exposure. Various methods, such as galvanization or protective coatings, can be used to protect steel structures from corrosion, ensuring their resilience and structural integrity over time. Furthermore, steel possesses excellent fire resistance properties due to its high melting point. This means it can withstand the extreme temperatures generated during fires or heat-related disasters without structural failure. Flexibility is another advantage of steel structures, as they can absorb and dissipate energy from wind loads and earthquakes. This flexibility helps prevent catastrophic failure by allowing the structure to deform and return to its original position, rather than collapsing under stress. Lastly, steel structures are designed to meet rigorous building codes and safety standards, taking into account factors like wind speeds, snow loads, and seismic activity. This ensures that they are specifically designed to withstand the weather conditions of the region they are built in. In conclusion, the strength, durability, corrosion resistance, fire resistance, flexibility, and adherence to building codes make steel an ideal material for constructing buildings that can withstand extreme weather conditions. This provides safety and security to those inside the structures.

Send your message to us

modern steel structure sculpture projects

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords