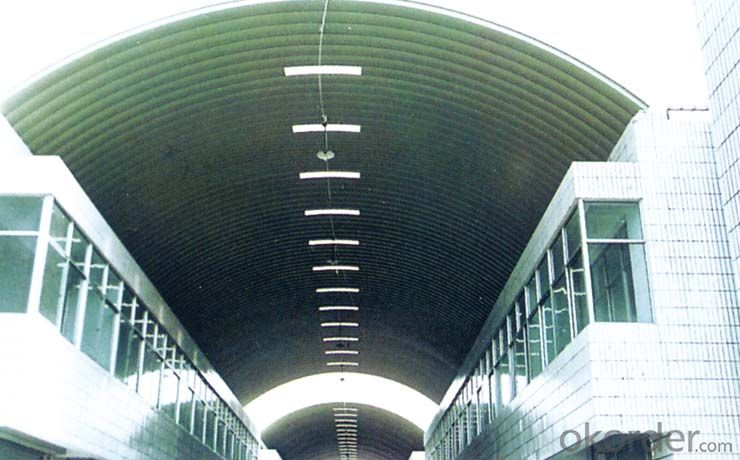

Prefabricated Light Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Steel Structure:

1.The steel structure of the connection method: welding connection

2.Steel structure design common norms are as follows: "Steel Design Code" (GB50017-2003) Cold formed steel structure technical specifications" (GB500182002) "Construction Quality Acceptance of Steel" (GB50205-2001) "Technical Specification for welded steel structure" (JGJ812002, J218 2002) "Technical Specification for Steel Structures of Tall Buildings" (JGJ99-98)

3.The characteristics of steel Light weight steel structure Higher reliability of steel work Steel anti-vibration (earthquake), impact and good Steel structure for a higher degree of industrialization Steel can be assembled quickly and accurately Large steel interior space Likely to cause sealing structure Steel corrosive Poor fire-resistant steel Recyclable steel shorter duration.

4.Commonly used steel grades and performance of steel Carbon

structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low alloy structural steel Quality carbon structural steel and alloy structural steel Special purpose steel Product Feature Carport, House, Office, Shop, Toilet, Villa, Warehouse, Workshop, Plant Other Information.

Products have been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North America, the Middle East, Africa, Asia and other countries and regions, the widespread use.

- Q: How do steel structures provide resistance against blast and impact loads?

- Steel structures provide resistance against blast and impact loads due to their high strength and ductility. The inherent properties of steel, such as its ability to absorb and distribute energy, make it a suitable material for withstanding sudden and intense forces. Additionally, the flexibility of steel allows it to bend and deform under extreme loads, reducing the risk of collapse. Moreover, the use of structural elements like bracing, framing, and reinforcement further enhances the resistance of steel structures against blast and impact loads by providing additional support and stability.

- Q: What are the considerations for designing steel pedestrian bridges for parks and trails?

- When designing steel pedestrian bridges for parks and trails, there are several key considerations to keep in mind. First and foremost, the safety of pedestrians should be the top priority. This involves ensuring that the bridge is structurally sound and can support the anticipated load, as well as incorporating appropriate handrails and non-slip surfaces. Additionally, the bridge should be designed to be accessible to people of all abilities, including those with disabilities or limited mobility. The aesthetics of the bridge should also be considered, as it should blend harmoniously with the natural surroundings and enhance the overall park or trail experience. Finally, factors such as durability, maintenance requirements, environmental impact, and cost-effectiveness should also be taken into account during the design process.

- Q: How are steel structures used in the construction of cultural centers?

- Steel structures are commonly used in the construction of cultural centers due to their strength, durability, and versatility. Steel frames and beams provide the necessary support for large open spaces, allowing for flexible and creative architectural designs. Additionally, steel's ability to span long distances without the need for intermediate columns makes it ideal for creating large auditoriums and exhibition halls within cultural centers.

- Q: How are steel structures connected?

- Steel structures are typically connected through various methods such as welding, bolting, and riveting. Welding is one of the most common methods used to connect steel components. It involves melting the edges of the steel pieces and fusing them together using heat and pressure. Welding provides a strong and permanent connection, making it ideal for structural applications. Bolting is another commonly used method of connecting steel structures. Bolts are inserted through pre-drilled holes in the steel components and tightened with nuts to create a secure connection. Bolting allows for easy disassembly and reassembly, making it suitable for applications where flexibility is required. Riveting is an older method that is still used in certain applications. It involves inserting a hot rivet into pre-drilled holes in the steel components and then hammering it to create a tight connection. While riveting is not as common as welding or bolting, it is still used in situations where aesthetics or historical accuracy are important. In addition to these primary methods, other techniques such as adhesive bonding and mechanical connectors can also be employed to connect steel structures. Adhesive bonding involves using epoxy or other bonding agents to attach steel components together, while mechanical connectors utilize specialized devices to join steel pieces. The choice of connection method depends on factors such as the load requirements, structural design, and the specific application of the steel structure. Each method has its advantages and disadvantages, and engineers must carefully consider these factors to ensure the safety, durability, and functionality of the steel structure.

- Q: How are steel structures designed for efficient waste management and recycling?

- Various strategies and considerations are taken into account when designing steel structures to efficiently manage and recycle waste. Firstly, steel is a highly recyclable material, allowing for easy dismantling and recycling of steel components at the end of a structure's life cycle. This reduces waste generation and decreases the demand for new steel production, which has a significant environmental impact. In terms of design, steel structures can include features that facilitate waste management. For instance, the design can incorporate waste storage areas or rooms, which enable the easy segregation and storage of different types of waste materials. This ensures cleanliness and organized waste management and disposal. Moreover, waste management systems such as waste chutes, compactors, and recycling bins can be integrated into steel structures. These systems promote efficient waste collection, segregation, and disposal within the building, reducing the need for manual handling of waste and encouraging recycling. In addition to physical design aspects, sustainable practices like rainwater harvesting and renewable energy generation can be incorporated into steel structures. Rainwater can be collected and utilized for various purposes within the building, reducing the need for additional water supply and minimizing water wastage. Integration of renewable energy sources like solar panels reduces reliance on non-renewable energy and reduces the building's carbon footprint. Overall, designing steel structures with efficient waste management and recycling involves considering the recyclability of steel, incorporating waste storage and management features, and integrating sustainable practices. These design strategies promote a more sustainable and environmentally-friendly approach to waste management in the construction industry.

- Q: What are the typical design considerations for steel retail or commercial buildings?

- Some typical design considerations for steel retail or commercial buildings include structural stability, durability, flexibility for future expansions or alterations, efficient use of space, cost-effectiveness, sustainability, fire resistance, and aesthetics. Additionally, factors like building codes, zoning regulations, and accessibility requirements also need to be taken into account during the design process.

- Q: How are steel structures used in mining and mineral processing plants?

- Steel structures are extensively used in mining and mineral processing plants for their durability, strength, and versatility. These structures are designed to support heavy machinery, equipment, and infrastructure required in mining operations. In mining plants, steel structures are utilized for various purposes. Firstly, they are used to provide a stable and secure framework for the processing and storage of mined materials. This includes structures such as storage bins, hoppers, and silos, which are essential for the efficient handling and stockpiling of minerals. Steel structures also play a crucial role in supporting and housing equipment used in mining operations. This includes structures like conveyor systems, crushers, screens, and mills, which are fundamental components in the extraction and processing of minerals. The strength and stability of steel allow these structures to withstand the heavy loads and harsh conditions encountered in mining environments. Additionally, steel structures are employed in the construction of mine shafts, tunnels, and underground infrastructure. These structures provide the necessary support and stability required for safe and efficient mining operations. They can withstand the immense pressure and ground movements that occur during mining activities, ensuring the safety of workers and the integrity of the mine. Furthermore, steel structures are used to create platforms, walkways, and access points within mining plants. These structures allow for easy and safe access to different areas of the plant, facilitating maintenance, inspection, and repair processes. The versatility of steel enables the construction of customized structures that can adapt to the specific needs and layout of a mining facility. Overall, steel structures are vital in mining and mineral processing plants due to their durability, strength, and adaptability. They provide the necessary support for heavy machinery, equipment, and infrastructure, ensuring the efficient and safe extraction and processing of minerals.

- Q: How are steel structures designed for educational buildings?

- Steel structures for educational buildings are designed with careful consideration of the specific needs and requirements of the educational institution. The design process involves a combination of architectural, engineering, and educational expertise to create a safe, functional, and aesthetically pleasing space for learning. Firstly, the design team assesses the functional requirements of the educational building. This includes determining the number and size of classrooms, laboratories, libraries, administrative spaces, and other facilities needed. The design must also consider factors such as accessibility, safety regulations, and any specific requirements for specialized equipment or technologies. Once the functional requirements are determined, the structural design begins. Steel is a popular choice for educational buildings due to its strength, durability, and versatility. The design team considers factors such as the building's height, span, and load-bearing capacity. They also take into account the local climate, seismic activity, and any other site-specific considerations. The design team uses computer-aided design (CAD) software to create a detailed 3D model of the steel structure. This allows them to visualize the building, analyze its structural integrity, and make any necessary adjustments before construction begins. The steel structure is designed to provide a safe and secure learning environment. This includes ensuring that the building can withstand extreme weather conditions, such as high winds or heavy snow loads. Fire safety is also a crucial consideration, with adequate fire-resistant materials and systems incorporated into the design. Additionally, the design team takes into account the aesthetic requirements of the educational institution. The steel structure can be customized to match the architectural style and overall design concept of the building. This includes selecting appropriate finishes, colors, and detailing to create an inspiring and visually appealing space for students and staff. In summary, steel structures for educational buildings are carefully designed to meet the functional needs of the institution while providing a safe and aesthetically pleasing environment for learning. The design process involves a comprehensive analysis of the site, functional requirements, structural integrity, and aesthetic considerations. By considering all these factors, educational buildings can be designed to meet the specific needs of the institution and create a conducive space for education.

- Q: What are the different methods of steel structure fire protection?

- To ensure the safety and integrity of steel structures in the event of a fire, there are various commonly used methods of steel structure fire protection. These methods encompass: 1. Intumescent coatings, which are widely employed for fire protection of steel structures. These coatings are applied to the steel surface and expand when exposed to high temperatures. This expansion creates an insulating barrier that slows down heat transfer, offering additional time for evacuation and firefighting efforts. 2. Fire-resistant insulation materials, such as mineral wool or fiberglass, are commonly utilized to safeguard steel structures. These materials are installed around the steel components to provide insulation and prevent rapid fire propagation. By reducing heat transfer and shielding from direct flame exposure, they assist in maintaining the structural integrity of the steel. 3. Fireproofing sprays, composed of cementitious materials or fiber-reinforced polymers, constitute another method of steel structure fire protection. These sprays are applied onto the steel surface and form a durable protective layer. This layer acts as a barrier against flames and heat, minimizing damage to the steel structure. 4. Fire-resistant boards, including gypsum or calcium silicate boards, are often employed for the fire protection of steel structures. These boards are installed around the steel members to create a protective barrier against fire. They are effective in preventing heat transfer and can withstand high temperatures, thus safeguarding the steel structure. 5. Structural fire-resistant coatings, specifically designed for steel structures, are made of epoxy-based or cementitious materials. These coatings are directly applied to the steel surface and provide a heat-resistant layer. By slowing down the rate of temperature rise on the steel, they prevent structural failure. It is crucial to consider factors such as fire rating requirements, building codes, and the specific environment in which the structure is located when selecting the appropriate method for steel structure fire protection. Involving professional fire protection engineers and consultants is essential to ensure compliance with applicable regulations and to provide the necessary level of fire resistance for the steel structure.

- Q: How do steel structures accommodate for thermal expansion and contraction?

- Various methods are employed in the design of steel structures to account for thermal expansion and contraction. One common approach involves the utilization of expansion joints or sliding connections. These joints permit independent movement of steel components when they expand or contract due to temperature fluctuations. Another technique involves the incorporation of flexible connections, such as bellows or flexible hoses, which can absorb the thermal expansion and contraction of steel components. These flexible connections can be strategically installed within the structure to allow for movement without imposing stress or damage on the steel. Furthermore, when designing steel structures, engineers take into consideration the coefficient of thermal expansion of the material. This coefficient quantifies the extent to which the steel will expand or contract in response to a given temperature change. By factoring in this coefficient, engineers can determine the appropriate clearance or space required to accommodate thermal movement without compromising the structure's stability. Moreover, the choice of steel used in construction can also influence how thermal expansion and contraction are managed. For instance, certain types of steel, such as low carbon or alloy steel, possess lower coefficients of thermal expansion than others. Consequently, they are better suited for structures that will be subjected to significant temperature variations. In conclusion, steel structures undergo meticulous design and engineering to effectively address thermal expansion and contraction. By utilizing expansion joints, flexible connections, considering the coefficient of thermal expansion, and making appropriate material selections, these structures can withstand temperature fluctuations while maintaining their structural integrity.

Send your message to us

Prefabricated Light Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords