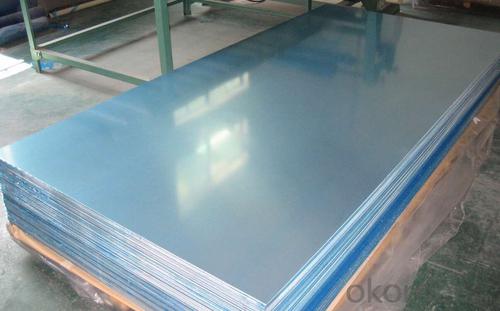

Mill Finished Aluminum Sheets 3xxx - Rolled Aluminum Sheets for Roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1000 series aluminum sheet is a commercially pure aluminum.

Excellent welding characteristics

Excellent ductile property

Excellent resistance to corrosion

Excellent conductivity

Application of 1000 series aluminum sheet

Chemical and food processing industries

Eye-appeal necessity needed material

Curtain wall material

Cookware material

Nameplate material

Decorative and reflective material

3000 series aluminum sheet is a commercially pure aluminum with the addition of manganese.

Good corrosion resistance

Excellent weldability,formability

Good corrosion resistance

Moderate strength

Specially, 3104 aluminum alloy is a typical deep-drawing material.

Application of 3000 series aluminum sheet

Food & Chemical processing and storage container

Deep drawing processing material

5000 series Aluminum Sheet is a typical Al-Mg aluminum product.

High stength

Good salt water resistance

Good low temperature ressistance

Application 5000 series Aluminum Sheet :

8000 series aluminum sheet for foil material

- Q: This question seeks to understand the specific characteristics of aluminum sheets that make them suitable for various applications.

- <p>Aluminum sheets possess several properties that make them versatile for different applications: 1. Corrosion resistance: Aluminum forms a protective oxide layer, which makes it resistant to corrosion. 2. Lightweight: Aluminum is lighter than many other metals, which is beneficial for applications where weight is a concern. 3. High strength-to-weight ratio: Despite being lightweight, aluminum is strong and durable. 4. Good thermal and electrical conductivity: Aluminum conducts heat and electricity well, making it ideal for heat sinks and electrical components. 5. Formability: Aluminum can be easily shaped and bent, which is useful in construction and manufacturing. 6. Recyclability: Aluminum is highly recyclable, reducing waste and environmental impact. 7. Reflectivity: Aluminum reflects light and heat, which is useful in applications like solar reflectors and insulation. These properties vary in importance depending on the specific application, such as construction, automotive, aerospace, or consumer goods.</p>

- Q: Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- Aluminum foil is just the metal called aluminum which has been pressed into a very thin sheet (foil), and metals won't melt or catch fire here and there till they get extremely hot (in huge furnaces). A home oven is waaay too cool for that. As for sticking, that depends on whether the foil is touching your patties and how much, as well as which ingredients you used in the patties since some will carmelize or dry out onto the foil but only where they contacted. You can always tent or make a dome with the foil so it doesn't touch any of the food though if you're concerned. Not sure why you'd be covering falafels though, since that will steam them (at least partly) not bake, them and therefore not create a crispy exterior.

- Q: What are the different methods of forming aluminum sheet?

- There are several methods of forming aluminum sheet, including rolling, extrusion, stamping, and spinning.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, meaning it can be easily manipulated without breaking or cracking. This property makes it ideal for various applications where flexibility and customization are required. Aluminum sheets can be bent, folded, rolled, or formed using a variety of techniques such as press brakes, rollers, or specialized forming tools. This versatility allows for the creation of complex shapes and structures, making aluminum a popular choice in industries like construction, automotive, aerospace, and manufacturing.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring.

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: What kind of aluminum sheet is most suitable for constructing the exterior walls of a building?

- <p>The best type of aluminum sheet for building exterior walls is typically aluminum composite material (ACM) or aluminum coil coated with a protective layer. ACM is lightweight, durable, and offers excellent resistance to weather and corrosion. It also provides good thermal insulation and is easy to install. Coated aluminum coils are often used for cladding due to their strength, low maintenance, and longevity. The choice may also depend on specific project requirements, such as aesthetic considerations, budget, and local climate conditions.</p>

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q: How does aluminum sheet perform in corrosive environments?

- Aluminum sheet performs exceptionally well in corrosive environments due to its inherent corrosion resistance. When exposed to moisture or various chemicals, aluminum forms a protective oxide layer that prevents further corrosion. This makes it a preferred choice for applications where resistance to corrosion is crucial, such as marine environments, chemical processing plants, and outdoor structures.

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

Send your message to us

Mill Finished Aluminum Sheets 3xxx - Rolled Aluminum Sheets for Roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords