Mill Finished Aluminum Sheets 3xxx for Construction and Trailer Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Mill Finined Aluminum Sheets 3xxx Used for Construction Description

Aluminum sheets 1xxx C.C quality is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum sheets 1xxx C.C quality is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Mill Finined Aluminum Sheets 3xxx Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

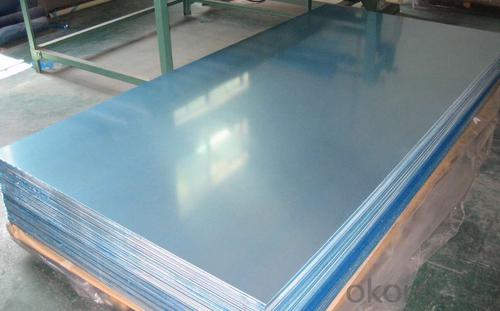

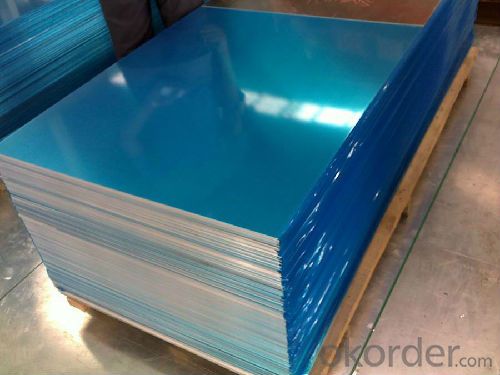

3.Mill Finined Aluminum Sheets 3xxx Used for Construction Images

4.Mill Finined Aluminum Sheets 3xxx Used for Construction Specification

Alloy | AA3xxx (AA3003, AA3105, AA3005 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Mill Finined Aluminum Sheets 3xxx Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: (1) Aluminum is malleable. (2) Aluminum reacts with sulfuric acid.(3) Aluminum conducts an electric current.(4)Aluminum has a density of 2.698 g/cm3 at STP.Explain why.

- The answer is choice 2. Why? It's the only one that describes a chemical interaction. The other three describe physical properties of aluminum, that is properties that do not involve a change in the chemical identity of aluminum metal. In choices 1, 3, and 4, the aluminum metal remains as aluminum metal. However, in choice 2, the metal reacts and becomes aluminum ion.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- Aluminum Vs Carbon Road Bike

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically determined by the specific alloy and thickness of the sheets. Aluminum has a relatively low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can deform or melt under high heat. However, it is worth noting that aluminum is a non-combustible material and does not contribute to the spread of fire. Its fire resistance can be enhanced through the use of fire-resistant coatings or by combining it with other fire-resistant materials. Ultimately, it is important to consult with manufacturers or industry experts to determine the fire rating of specific 101 aluminum sheets.

- Q: What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers.

- Q: What are the different methods of surface preparation for aluminum sheets?

- Aluminum sheets can undergo various surface preparation methods to ensure optimal adhesion and paint durability. Below are different techniques for preparing aluminum surfaces: 1. Utilizing Mechanical Abrasion: This method involves physically eliminating any dirt, rust, or oxidation from the aluminum surface using materials like sandpaper, wire brushes, or sandblasting. Mechanical abrasion creates a rough texture that enhances paint adhesion. 2. Employing Chemical Cleaning: Chemical cleaning employs acidic or alkaline solutions to eliminate contaminants or oxidation from the aluminum surface. This technique is particularly effective for tough stains, oils, or greases. After chemical cleaning, thorough rinsing removes any residue. 3. Implementing Etching: Etching entails applying an acidic or alkaline solution to create a microscopically rough texture on the aluminum surface. This roughness improves paint adhesion and provides a better bonding surface for coatings. Etching is commonly used as a pre-treatment before applying primers or paints. 4. Applying Conversion Coating: Conversion coating involves applying a chemical solution to create a thin, protective layer on the aluminum surface. This layer not only enhances paint adhesion but also provides corrosion resistance. Examples of conversion coatings for aluminum include chromate conversion coatings and phosphoric acid anodizing. 5. Performing Mechanical Cleaning: Mechanical cleaning involves brushing, scraping, or buffing to remove loose particles, dirt, or debris from the aluminum surface. This method is often used as an initial step before applying other surface treatments or coatings. It is crucial to note that the choice of surface preparation method may vary based on the aluminum sheet's specific requirements, surface condition, and desired finish. Proper surface preparation is essential for ensuring the longevity and performance of the applied paint or coating on aluminum sheets.

- Q: This question asks for methods to determine the thickness of aluminum sheets.

- <p>To measure the thickness of aluminum sheets, you can use various methods including mechanical thickness gauges, ultrasonic thickness gauges, or calipers. Mechanical gauges are simple and involve sliding a foot along the sheet until it bottoms out on both sides. Ultrasonic thickness gauges use sound waves to measure thickness and are non-destructive, providing accurate measurements. Calipers can also be used for manual measurement, though they may be less precise for very thin sheets. Always ensure the measuring device is calibrated and suitable for the material and thickness range of the aluminum sheet in question.</p>

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To determine the thickness tolerance of an aluminum sheet, several factors need to be considered. Firstly, it is important to refer to the industry standards and specifications for aluminum sheets. These standards typically provide guidelines and tolerances for various thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Next, it is crucial to use precise measuring equipment such as calipers or micrometers to accurately measure the thickness of the aluminum sheet. Multiple measurements should be taken at different locations on the sheet to account for any potential variations. Once the measurements are obtained, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance typically represents the acceptable range within which the actual thickness of the sheet can vary. For instance, if the specified thickness tolerance is ±0.002 inches, it means that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is considered to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In some cases, it may be necessary to consult with the manufacturer or supplier of the aluminum sheet to determine the specific tolerance requirements for a particular application. They can provide additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet meets the intended purpose. Overall, determining the thickness tolerance of an aluminum sheet involves following industry standards, using accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This helps ensure that the sheet meets the required specifications and can be used effectively in various applications.

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable.

Send your message to us

Mill Finished Aluminum Sheets 3xxx for Construction and Trailer Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords