LOW CREEP FIRECLAY CHECKER BRICKS FOR HOT BLAST FURNACE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | Low Creep Fireclay Checker Bricks for Hot Blast Furnace |

Material | Fire Clay |

Quality Code | DRN120, DRL125 |

Al2O3 | 40 - 42% |

Supply Ability | About 100000 tons per year |

Package | Wooden pallet with plastic films |

Loading port | Tianjin port |

Lead time | 30 days for 300 tons To be confirmed for other quantities |

Features

1. Very low creep rate

2. Excellent Refractories under Load

Technical data for LOW CREEP FIRE CLAY BRICK DRN-120

ITEMS | UNIT | VALUE |

Al2O3 | % | ≥42 |

Fe2O3 | % | ≤2.5 |

Bulk Density 体密 | g/cm3 | 2.1 |

Apparent Porosity 气孔 | % | ≤24 |

CCS 常温耐压强度 | Mpa | ≥35 |

0.2 MPa RUL 荷软, 0.2MPa | ℃ | ≥1400 |

Refractoriness 耐火度 | ℃ | ≥1750 |

0.2 Mpa Creep Rate 1200℃×(0~50)h 蠕变率, 0.2MPa, 1200℃×(0~50)h | % | ≤0.8 |

Photos

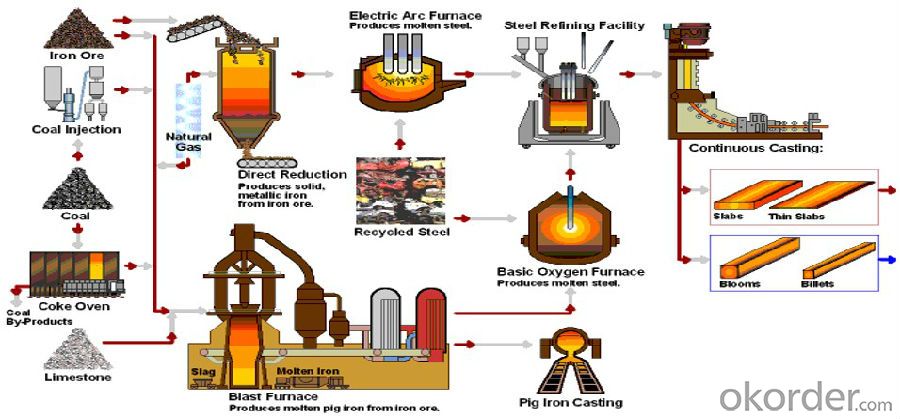

Refractories for all process in steel mills

Factory photos

Package

Company profile

CNBM Group is short for China National Building Materials Group Corporation, which is established in 1984 with approval from the State Council

CNBM Group is the largest comprehensive building materials industry group in China.

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

- Q:What kind of refractory brick is used for industrial furnace?

- What kiln? Glass kiln, ceramic kiln, or blast furnace?

- Q:How to choose the proper refractory bricks when buying the refractory bricks?

- Crack condition. 4. 6. Inspection of dimensions. Conditions of pits and swells and lack of edges or angles. The inspection of refractory bricks' appearance quality and the condition of the affecting with damp.

- Q:refractory bricks of fireclay

- According to the preparation process, it can be divided into bricks, high alumina brick, magnesia brickand so on, such as refractory clay brick, and ordinary brick; according to the shape and size, it can be divided into standard brick and silica?brick, it can withstand all kinds of physical and chemical changes and mechanical action at high temperature; silica?brick can be used as high-temperature building materials and structural material to build kiln and kinds of thermal equipments. Refractory material and fused brick with a certain shape and size are called refractory?brick for short.

- Q:What is the difference between fused brick and clay brick?

- Artificial small bulk for building. Also called sintered brick. Clay to clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting and. Chinese in the spring and Autumn period has created a square and brick, Qin and Han Dynasties brick technology and production scale, quality and variety have significant development, known as "Qin Zhuanhan tile". Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

- Q:In tunnel kiln, what is the meaning of refractory proportion 2.0?

- That is the volume density of the refractory brick

- Q:what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q:does 90m high reinforced concrete chimney need firebrick?

- The chimney need firebricks or casting fire or acid resisitant concrete after casting, one aim is to resist high temperature, then is to resist acid corrosion. there is a variety of models of the refractory brick , you can refer to the installation quota.

- Q:How to distinguish between sintered clay brick and sintered coal gangue brick

- Fired fly ash brick is a common brick made of fly ash as main raw material and mixed with cement such as coal gangue powder or clay. It is made up of ingredients, molding, drying and roasting. The utility model is characterized in that the clay can be saved, the fuel is saved, and the environment is protected. Because its wood property is the same as that of sintered clay brick, and its weight is lighter than that of the latter, it is a new type of sintered wall material which is easy to be popularized and applied.

- Q:Can porous clay bricks be made of 12 walls to bear weight?

- Porous brick using cement as binder, and sand, stone (aggregate) by adding water and mixing, molding and maintenance made with a plurality of rows of holes of the concrete products; after ordinary and lightweight aggregate concrete small hollow block and a variety of new wall materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LOW CREEP FIRECLAY CHECKER BRICKS FOR HOT BLAST FURNACE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords