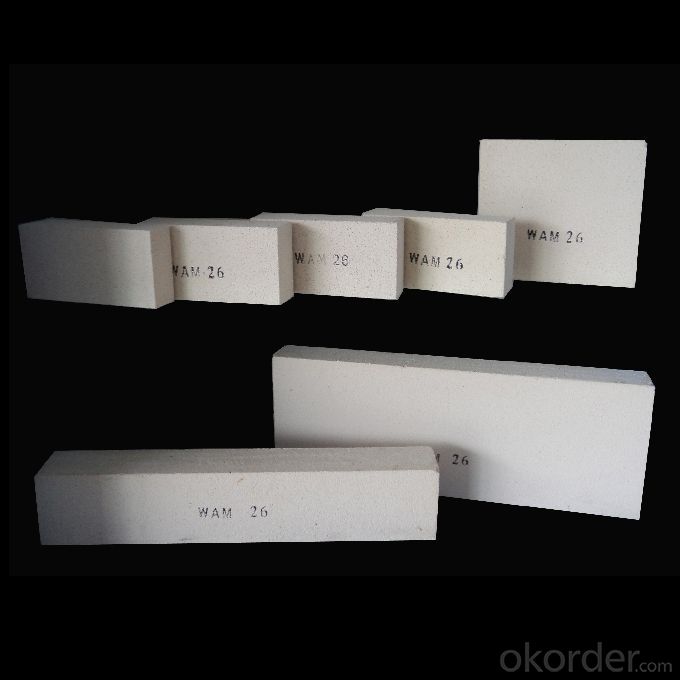

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick GJM28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used in the construction of refractory-lined vessels?

- Yes, insulating fire bricks can be used in the construction of refractory-lined vessels. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for lining vessels that require heat insulation and refractory properties.

- Q: Can insulating fire bricks be used in chimneys or flues?

- Insulating fire bricks are not recommended for use directly in chimneys or flues. While these bricks are designed to withstand high temperatures, they are primarily used for insulation purposes rather than as a structural component. Chimneys and flues require bricks that are specifically engineered to withstand the intense heat and corrosive byproducts of combustion. These bricks, known as refractory bricks, are designed to have high thermal resistance and exceptional durability to ensure the safe and efficient operation of the chimney or flue. Therefore, it is advisable to use refractory bricks instead of insulating fire bricks when constructing or repairing chimneys and flues.

- Q: Can insulating fire bricks be used as a lining material for boilers?

- Yes, insulating fire bricks can be used as a lining material for boilers. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in boiler linings.

- Q: How do insulating fire bricks help reduce fuel consumption?

- Insulating fire bricks help reduce fuel consumption by providing excellent thermal insulation, which minimizes heat loss and increases the efficiency of the heating system. This means that less fuel is required to maintain the desired temperature, resulting in reduced fuel consumption and cost savings.

- Q: Can insulating fire bricks be used in brick kilns?

- Insulating fire bricks are indeed capable of being utilized in brick kilns. These bricks are specifically crafted to possess high thermal resistance, rendering them an excellent option for insulating the walls of a brick kiln. With the ability to withstand exceedingly high temperatures, they assist in maintaining consistent heat levels within the kiln. Through the utilization of these insulating fire bricks, the kiln's heat loss is significantly reduced, consequently enhancing energy efficiency and diminishing fuel consumption. Furthermore, employing insulating fire bricks also serves to safeguard the outer layers of the kiln from excessive heat, thereby preventing any potential damage and extending the kiln's lifespan. All in all, insulating fire bricks are a suitable and highly effective choice for implementation in brick kilns.

- Q: Can insulating fire bricks be used in the construction of steam boilers?

- Insulating fire bricks are ideal for use in steam boiler construction. They are crafted from lightweight refractory materials that offer outstanding thermal insulation capabilities. These bricks are specifically designed to endure high temperatures and provide insulation in industries where heat retention is crucial, such as steam boiler construction. The advantage of using insulating fire bricks lies in their low thermal conductivity, which allows for effective heat loss reduction and enhanced energy efficiency in steam boilers. When these bricks are incorporated into the construction of steam boilers, the overall heat transfer efficiency increases, resulting in reduced fuel consumption and lower operating costs. In addition, insulating fire bricks possess exceptional resistance to thermal shock. This means they can withstand sudden temperature fluctuations without cracking or breaking. This quality is particularly significant in steam boiler applications, where the temperature can vary greatly during operation. To summarize, insulating fire bricks are an excellent choice for steam boiler construction due to their remarkable thermal insulation properties, low thermal conductivity, and resistance to thermal shock. They contribute to improved energy efficiency, decreased fuel consumption, and the long life of the boiler.

- Q: Can insulating fire bricks be used for insulation in ovens and kilns?

- Yes, insulating fire bricks can be used for insulation in ovens and kilns. They are designed to withstand high temperatures and provide excellent thermal insulation, making them an ideal choice for these applications.

- Q: Do insulating fire bricks require special handling?

- Special handling is necessary for insulating fire bricks. These bricks are manufactured using lightweight refractory materials and are specifically engineered to endure high temperatures. Because they are delicate, they must be treated carefully to avoid any breakage or harm. It is advised to employ appropriate lifting and carrying methods, including the use of gloves and tongs or lifters, in order to prevent accidents or injuries. Moreover, it is crucial to store insulating fire bricks in a dry and sheltered location to prevent moisture absorption, which can impact their thermal characteristics.

- Q: What is the maximum temperature that insulating fire bricks can withstand?

- Insulating fire bricks can withstand temperatures up to 3000°F (1650°C).

- Q: Can insulating fire bricks be used for insulation in chemical storage tanks?

- Indeed, insulation in chemical storage tanks can be achieved by utilizing insulating fire bricks. These bricks, purposefully engineered to offer exceptional thermal insulation, lend themselves well to a wide range of industrial uses, including chemical storage tanks. Their outstanding insulating properties stem from their low thermal conductivity, ensuring minimal heat transfer and a consistent internal temperature within the tank. Moreover, these fire bricks exhibit remarkable resistance to high temperatures and the corrosive effects of various chemicals, rendering them a fitting option for insulation in chemical storage tanks.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick GJM28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords