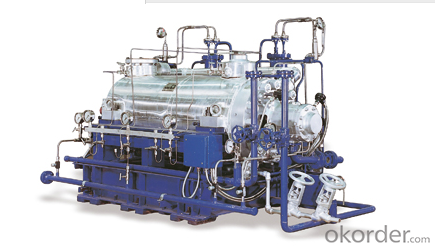

Horizontal, high-pressure barrel-type pump CHTR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design |

Overview of technical data

| Type of installation | Long- coupled |

| Type of bearing | Rolling element and plain bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 7. 000 1/min |

| Maximum flow rate | 1. 450 m³/h |

| Maximum discharge-side pressure | 400 bar |

| No. of impeller entries | Single / Double entry |

| Casing material | Duplex steel; Carbon steel;Chrome steel |

| Suction characteristics | Non- priming |

| Pull-out design | Yes |

| Other impeller types | Closed / Radial |

| Barrel casing | Yes |

| Pump set location | Dry installed |

| Type of suction casing | Annular casing |

| Max. permissible fluid temperature | 400 °C |

| Type of discharge casing | Annular casing |

| Main applications | Industry and process engineering; Energy;Oil / Gas |

| Type of installation | Stationary |

| Type of connection | Flange, weld ends |

| Type of lubrication | ( forced) oil lubrication |

| Type of drive | Electric motor, turbine |

| Installation position | Horizontal |

| Maximum suction pressure | 30 bar |

| Type of coupling | Direct; Gear;Variable speed coupling;Geared variable speed coupling |

| Shaft seal type | Mechanical seal |

| Maximum head | 4. 000,00 m |

| Type of stage casing | Stage casing with diffuser |

| Nozzle position | Variable |

| Casing partition | Radially split |

- Q: Working principle and diagram of axial piston pump with pressure compensation variable

- The size of the outlet flow pressure compensated variable displacement pump with outlet pressure of approximately in a certain range according to the constant power curve. When the pressure oil from the main part of the channel (a), (b), (c) into the inferior vena cava (d) variable shell, oil by the channel (E) respectively into the channel (f) and (H), when the spring force is greater than the oil (f) into the lower end of the piston ring servo hydraulic thrust area when the oil liquid (H) to the chamber (g), push the variable downward movement of the piston, the pump flow increases. As for the hydraulic servo piston end thrust force ring shaped area is greater than the spring when the servo piston moves upward, blocking channels (H), the (g) (I) through the cavity of the oil cavity pressure relief, at this time, the piston moves up, the variable head angle decreases, the pump flow rate decreases.

- Q: How many millimeters is the diameter of the water outlet of the four inch pump?

- This question is of no practical significance. The user does not care about this figure. The concern should be the nominal diameter, which is fitted with flanges and pipes. Moreover, the pump shell is cast iron, the inside diameter is not processed, and there is no matching parts, there is only one manufacturing size.

- Q: Excuse me, what is the water pump from the lotus root?

- Submersible sewage pump with septic tank, outlet pipe automatic coupling installation, dipping down can be.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- Product featuresThe integrated structure of motor and pump adopts static seal, so that the pump is completely free of leakage;Full closed and no leakage structure, can transport toxic and harmful liquid substances;The shielded water-cooled motor and the cooling fan are removed to make the pump operate in a low noise and quiet condition. The utility model is suitable for occasions with high environmental noise requirements;

- Q: How many pumps does the 80cm tank use?

- Mainly look at the flow of the pump, all pumps have flow signs, such as 15L/HThe above is I at random, meaning that 15 litres per hour. You should calculate the volume of your cylinder, that is, the length of the tank, the width and the height of the water surface, the unit is cm. The result is 1000, which is the volume of your fish tank

- Q: What should be used to pay attention to the use of mechanical pumps?

- There are many kinds of pumps, such as centrifugal pumps, piston pumps, diaphragm pumps, vane pumps, gear pumps, etc.

- Q: Why is the flow of the pump too small will occur cavitation phenomenon?

- Throttling regulation is to change the opening of the valve to change the flow of the pump, that is to say, to change the characteristic curve of the pipeline. The commonly used to regulate the flow of exports, because the entrance throttle makes reduce the inlet pressure caused by cavitation danger.

- Q: Is vane pump good or gear pump good?

- 1) the reversible design of gear pumps can also usually reverse, but reverse after the suction port change, and the pump safety valve does not work; leaf pump is generally not allowed to reverse. 3) the single acting vane pump can be designed to change the eccentric distance by moving the stator at the constant speed, so as to achieve the purpose of variable direction.

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- When the valve is closed, the flow of the pump is close to zero, the power of the pump is very small, which reduces the load that the motor starts to bear and has a protective effect on the motor. Therefore, the valve closed to start the pump.

- Q: What are the differences between the sewage pump and the clean water pump?

- The main difference between the sewage pump and the clean water pump is that:Impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.

Send your message to us

Horizontal, high-pressure barrel-type pump CHTR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords