Homemade Beer Fermentation with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

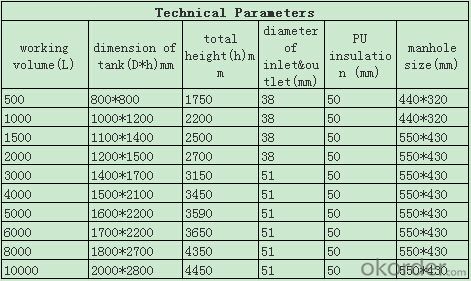

Specifications

1.manhole 2.CIP spraying ball 3.adjusting feet 4.sample valve 5.temperature gauge 6.pressure gauge 7.level gauge

- Q: I have recently experienced my boiler losing pressure. I can reinstate the pressure using the valves underneath but over time it goes again. I have read on other forums that I can isolate the boiler with pressure up for a period of time and this will tell me whether the fault is with the unit or somewhere else in the system. Only problem - no one tells me what this isolating involves! Can anyone advise step by step what i do? Is it as simple as turning the heat and hot water off?Thanks

- The only way you can isolate the boiler would be to shut off the supply and return, but there's not typically valves installed in those pipes....and even if there were, it'd be a bit of luck if they sealed well. If your boiler is leaking, you'll usually see that one or more of the burners are badly rusted from water leaking on them. If you take the vent hood off, you can usually see any cracks or rotted parts just by giving it a close inspection. Depending on the boiler, you may have to at least partially remove the jacket as well.. Hope this helps

- Q: High temperature and high pressure boiler drum material which

- Boilers that produce steam are called steam boilers, often referred to as boilers, for thermal power plants, ships, locomotives and industrial and mining enterprises.

- Q: I saw a television show in which a person set the boiler in their apartment to a certain temperature. Is it some kind of cooking appliance? Or perhaps a furnace or space heater?Thanks!

- Just wanted to add, that some modern boilers do NOT have a tank of water that is heated. A boiler is like a furnace yes. We have a boiler in our kitchen. You turn it on, it fires up and heats the water AS it runs through the pipes when you shower or turn a hot tap on. We do not have a water tank as we have what is called a combi boiler. When we want heat, we press the switch on the boiler and that then heats the water IN the radiators than hang on the walls in each room. A boiler and a radiator are two separate things!

- Q: The boilers water pump does not have enough pressure to top up pressure through filling loop have to do it by manual water hand pump

- The two matters to which you refer are totally unconnected. The pump in the boiler is to circulate heating water around the heating system. If you cannot pressurise the system with the filling loop properly then the boiler should not have been installed in the first place. A combi boiler needs a minimum working pressure and flow rate to work properly. I would suggest firstly you get the installer back if its just been fitted or contact the water board to see why you pressure is so poor.

- Q: Is that not supposed to be an outside hose spigot?I followd the copper pipe, and it merges with a pipe that comes out of the boiler, but not from the normal hot water ends.wondering if its not supposd to be an outdoor spigot

- Without being able to see it and run some tests this answer is an educated guess! I suspect that your tracing of the pipe back to the boiler conclusion that it's NOT from the normal hot water outlet pipe indicates that it is tapped into the cold water inlet supply pipe TO the boiler. IF that is the case, I also suspect that the spigot is just an outside cold water supply for which whoever installed it did NOT have a normal exterior spigot, and used that yellow handled valve [which by the way is probably a Ball valve which is much better than the ordinary faucet]. Test by opening the valve for a couple of minutes to confirm water flow, and determine IF it's cold water, or hot. IF cold I still stand by my above suspicions.

- Q: what does boiler plate mean? where does it come from?

- Boilerplate Language

- Q: why did our boiler stopped working. Burner does not turn on. how to turn it on. i think i have to reset. please guide.

- get a gas safe engineer do not fiddle with the boiler

- Q: also the boiler is from the 1970s

- Really not enough information. Smoke or steam ? How much and what type of damage, to what ? and was the fire out, ( in the boiler). Gas or oil fired ?

- Q: What is a 10t / h boiler, an electric boiler or a fuel boiler?

- This is the thermal index of the boiler and can not be seen as electric or fuel.

- Q: my husband wants to know!

- Remember that Pulse furnace a few years back? That was a true condensing unit. A regular boiler operates at a HIGH exhaust temperature, thereby exhausing all condensate products up the flue. Natural gas or coal have a byproduct of combustion of water and Co2 and some Co A condensing furnace has MORE And LONGER tubes in it and it allows the gasses inside the boiler to reach a much much LOWER exhaust temp up the stack. Thus CONDENSING takes place. This is a much more efficient process as more heat is extracted from the fuel and less goes up the chimney. Problem is that the CONDENSATE forms on the inside tubes of the furnace, it is acidic and eats away at the tubes. The new furnaces are designed to take that corrosion. An old boiler or furnace is about 75 to 80 % eff. A condensing new boiler or furnace is about 92% efficient. These new ones have longer tubes and more of them and can take corrosion and they of course cost a lot more.

Send your message to us

Homemade Beer Fermentation with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords