HCSA Cement 92.5MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 10000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HCSA BINDER is manufactured under a strict quality assurance systems GB/T 19001-2000 and GB/T 24001-1996 which accommodates the

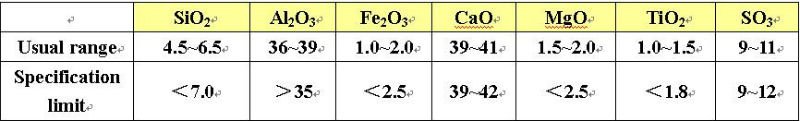

Chemical Analysis

The chemical analysis of HCSA BINDER has been determined according to the following:

GB/T 176-1996 Methods of chemical analysis for cement

Main constituents (%)

Fineness

Specific Surface Area: according to standard GB/T 8074-1987

Usual range: 360~430 m2/kg

Specification limit: >360 m2/kg

Reactivity with Portland cement

HCSA BINDER may be used in combination with other mineral products, for example PORTLAND cement, calcium sulphates and fillers, or with organics such as polymers in latex form or in redispersible form.

Depending on the type of mixes and technology employed, HCSA BINDER can be used to obtain and control various properties.

The behaviour of PORTLAND cement is vary variable. In general, acceleration of set increases progressly with the addition of HCSA BINDER. The amount of HCSA BINDER needed to obtain a specific setting time varies considerably depending on the origin of the PORTLAND cement and performance can be modified with the use of additives.

The strength development of HCSA BINDER/PORTLAND cement and/or Calcium Sulphates depend on the nature of the PORTLAND cement and/or Calcium Sulphates used. In general these mixes will develop mechanical strength at a very early stage (several hours). With some type of PORTLAND cements and in formulated products containing additives which control the setting and hydration, the long term properties is similar to those of the original PORTLAND cement, however it is necessary to check the behaviour of each PORTLAND cement used.

The characteristics of PORTLAND cement to be considered are:

1. C3A content

2. Mineral admixture type and content

3. Type of Calcium Sulphate used

Additives will also influence the properties of these mixes:

1. Setting time

2. Rheology

3. Mechanical performance

These properties are applied to obtain a wide range of products:

1. Fast setting cements

2. Rapid hardening mortars

3. Tile adhesives

4. Self-leveling compounds

5. Non-shrink grouts

6. Water stopping mortars

7. etc.

With a careful selection of the constituents (OPC, calcium sulphates, additives), it is possible to create mixes with a range of different hydraulic properties:

1. Adjustable setting time

2. Rheology adapted to the application

3. High early strength

4. High long term strength

5. Shrinkage compensation

Use of Additives

HCSA BINDER may be used in combination with chemical additives such as:

1. polymers, either in latex form or redispersible powder form

2. defoamers

3. retarders

4. accelerators

5. plasticizers/superplasticizers

6. rheology modifiers

7. fibers

- Q: ok, can the mixture of sperm and female ejaculate cause you to get stuck if no cleaned up for hours?

- well there isn't any way to be delicate about this you may just become a little crusty is all but no you wont make cement

- Q: i needed regrouting done on the paved edges of my swimming pool, the guy i hired done the job but he didn't clean the pavers afterwards properly so now there's a very slight film of cement grouting washed over the pavers - it makes them look slightly powdery. He said it would wash away but since then there's been heavy rain a few times but it still hasn't come off. What do you suggest i do to remove that residue? I thought about hydrochloric acid but I was worried it might damage the natural sheen in the pavers? what do you think...............

- For removing a light haze try regular vinegar. It is a mild acid and works well in this application. I use a plastic spray bottle and a medium bristle brush. Spray an area and scrub with brush rinse with clear water. May take a couple applications.

- Q: estimate the heat-flow rate for a solid cement wall of a typical-size house. assume the wall is 5.0 m wide and 2.5 m tall.please show work and equations if possible! thanks everyone, i appreciate it!

- 42 W/m degC as a thermal conductivity value for light concrete. This means that .42 W will flow through a concrete wall 1 meter thick if the temperature difference on opposite sides of the wall is 1 deg C if the wall is thinner or the temperature difference is bigger then more will flow this makes sense, if it is hotter outside and the wall is thinner more heat comes in so, if it is 30 deg C outside, and 20 deg C inside, the temperature difference is 10 deg C if the wall is about 8 inches thick (or say .2 meters) then our flow is .42*10*(5*2.5)/.2 W/m-degC m*m/m = 263 Watts if I didn't make an arithmetic mistake, then then that should be a reasonable estimate

- Q: What kind of cement (and where can I get it $$$$) can I use to replace it without going back to the dentist?

- You definantly need to go back to the dentist... there is no way around that one!?!?

- Q: Can cement be mixed with sea water instead of fresh water?

- This is definitely not a good idea as there will be a reaction between the cement and the salt. Even though the cement will appear hard it will be weakened by the salt. There may however be special cements which are made to be mixed with sea water. Bill

- Q: What type of cement/concrete do I use for making broken glass countertops?

- Broken Glass Countertops

- Q: I'm building a wood fence with metal posts this weekend. How long do I need to let the cement cure for?

- Depends on the cement you use. If it's a quick set kind, it will say on the bag (probably a coupla-few hours tops). If it's just regular Portland cement, wait a day or two (or whatever it says on the bag).

- Q: The cement board now has holes, tons of marks, glue, bad wallpaper you name it. Can I place drywall over it in order paint it? I plan to replace the tile from the waist down but on the upper wall I want to paint. Any tips are appreciated.

- Fir it out as necessary and re drywall it with green board drywall. It will look much better and be right.

- Q: White cement accidentally wash clothes how to do, how can we remove, thank you

- And then slowly rubbing, rinse with water several times, do not add bleach, bleach will make the clothes lighter color

- Q: I am wanting to add a cement patio on to my house and in order to build a $6000 patio, I have to pay a $5000 road bond to the village does that make sense

- Bonds are not insurance. What they are asking for is that you provide a bond to promise to pay up to $5000.00 if the cement truck damages the roads it is travelling on. You go to a bonding company (sometimes your insurance company will provide the bond), pay them a fee for providing the bond and have the work done. If the truck damages a road, the bonding company will pay out up to $5000.00 for the damage, then you will have to reimburse the bonding company for it's outlay. Bonds are NOT insurance.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Mid East; Eastern Asia; Western Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang, Jingtang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Japanese, Russian, Korean |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

HCSA Cement 92.5MPa

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 10000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords