Glazed Tile CMAX-BR653

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

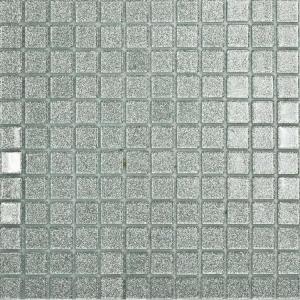

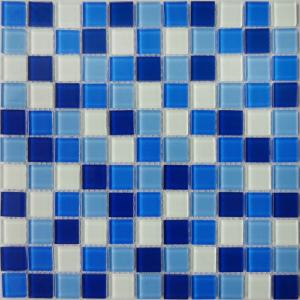

You Might Also Like

Key Specifications/Special Features of Glazed Tile CMAX-BR653:

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages of Glazed Tile CMAX-BR653:

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification:

Tile type: | Ceramic tile |

Material: | Porcelain |

Size(MM) : | 600x600mm |

Thickness(MM): | 9mm |

Water Absorption: | ≤0.5% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Glazed surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Acid-Resistant, Antibacterial, Heat Insulation, Non-Slip, Wear-Resistant, Anti-fouling easy to clean |

Packaging: | 600x600mm: 4pcs/box,28kg/box,standard cartons and wooden pallets packing |

Remark: | All kind of designs can be produced according to your requirements |

Quality | |

Surface quality: | 95% tiles no defect from 0.8 away uprightly |

Breaking strength: | As require |

Resistance to thermal shock: | Without crack and flaw after 10 times anti heat shock test |

Brightness: | ≥55 |

Frost-resistance: | No crack or spalling after frost resistance test |

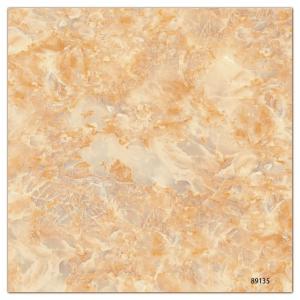

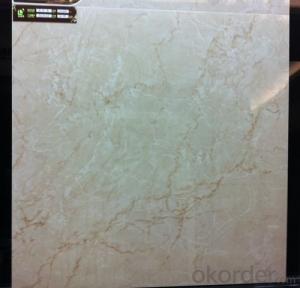

Product Picture:

Packing Pictures

- Q:I‘m redoing my shower and want a tile floor at least. The bottom of the floor is about 6‘x6‘. I either want big tiles or the smaller tiles that are already connected on the back of them. Ideas?

- Where I live we have a place that sells used house fixtures. They go to demolition sites and scavage everything that is usable. They resell it and the proceeds go to the Habitat for Humanity. You can often get very inexpensive materials there. Maybe your city has a place like this too.

- Q:My husband and I are going to try tiling the kitchen floor ourselves. Can someone please give me step by step instructions on how it should be done and also waht materials we will need. Also any pointers or tips are really apperciated. FYI: We will be using 18 inch porcilin tile.

- the 1st factor is i'd desire to understand is this laminate glue or snap at the same time (do you desire to maintain this floor ?) in case you donot care that's a thank you to eliminate your laminate first of all determine which way the laminate is started out this provides you with a solid beginning factor. this would desire to easily fold up ward ____/ like that once you start up up you will desire to have the capacity to soak up thold laminate in one million hour. determine you eliminate all your wall base first., that's what holds down the laminate. After it is up you will would desire to confirm what style of underlayment is on the subfloor. the main person-friendly is durock in case you're putting down ceramic . despite if that's vinyl tiles then you would desire to apply luan (one million/4 thick use the comparable thickness for the durock). you will desire to degree you length and width of the floor magnificent chalk lines to confirm the place your beginning factor is ( you do this with the two style of floor).in case you like extra preparation e mailme.

- Q:Home decoration with what tiles better

- Research a lot of tiles, online tattoo comments brand tiles are: the famous Dongpeng many Shandong Zibo OEM turn, just advertising to do bright! Shop out is not smooth! Marco Polo also has a lot of branded brick! Comments that gold pottery is rubbish, poor service! Commented that the generals serious uneven, I really experience from the physical shop what is the stone arch bridge! Commented that Samit was serious in the drum, I also deliberately in the physical store is indeed the case, I have been set and back! Online comment Nobel is not flat, this I did not see! Gold rudder is expensive! ... ... I want to buy a brand name of the number of friends to the brand Tucao finished, not scolded like only Hongyu and crown beads, so I deliberately went to the two stores looked, really fabulous, but hit Hongyu sound Crisp, may be good bricks, but the price is very expensive, in our reputation there is no crown beads, so into the crown beads shop, but also very expensive. I deliberately poured the floor of the small floor of the brick, actually did not infiltrate a minute, so I decided to buy beads, but the price seems to be as expensive as Hongyu, only buy crown beads tiles and toilet bricks, to save money, kitchen brick to buy A miscellaneous brand. Hope that the crown will not let me down!

- Q:I‘m planning to tile up my space. It‘s a 27 square meters. I‘ve calculated the number of tiles. It will be around 140 to 150 pieces with extra tiles. How much or how many bags of tile adhesive will I consume for the 27 square meters space using 150 pieces of tiles? or What is the area a bag of tile adhesive could cover? Can you show me a computation.

- You don t say what size tile it is and what your going over as far as a substrate. It makes a difference. Since I familiar with the coverage in s/f and your post suggests you came from the states I ll use a s/f format and some generalizations. Assuming you have a larger tile you should be using a larger notched trowel.1/4x3/8 but you may want to use a larger 1/2x1/2. I ll go off of a 1/4x3/8 trowel. A standard 50# bag of thin set will cover an area of 60/70 s/f using a 1/4x3/8 trowel. Splitting the difference and using 65 s/f per bag, divide 65 into the 290 s/f you have. Or 4.46 bags. So you ll need 5 , 50# bags of thin set using a 1/4x3/8 trowel. If your using a different size trowel , all bags have a coversion chart on the back to figure your coverage. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:I want to use the tiles for a back splash in the kitchen. Is there a reason I have to use the spacers? Why can‘t I put them where they are touching each other? I‘m not using them on a floor. I don‘t like the look of the space between the tiles.

- the spaces are important on wall tiles because you need the grout for extra support. Think about it. If the only support you have is on the bottom of the tiles, their is an increase chance of the tiles falling. The grout around each tile makes each tile attached independently having also side support.

- Q:I am installing 13x13 porcelain tile on a wall. Should I leave a 1/4‘‘ gap for grout or can I butt them up tight for a smaller grout line?

- You have to leave some gap for grout. Butting them together would not work.

- Q:I have some old dark tile in our entry way. It‘s not an option right now to replace it, so I‘d like to make it look better if possible. When I mop it and it looks nice and shiny. Then when it dries it looks dull. Is there any way to make it shiny all the time?Thanks

- You could try to re-seal the tile. Is your tile glazed? Glazed tiles should never need to be sealed, as the glaze is the sealer. Do a water test first to see if your tile is soaking up water. Put a little water on the tile if it turns dark, then your tile needs to be re-sealed. If you just want to make it shiny, you can try a topical sealer. Your local tile/flooring store should be able to help you pick the best one. There is also something called a 'wear layer' which is an acrylic floor finish that helps to keep you from wearing through the sealer. Again, your local tile store can help you with this step.

- Q:Kitchen tiles, that are like whitish/beigish?

- yes you can use tiles

- Q:I applied sealer to Mexican tile and within a few hours, it rained.The finish on the tiles now is cloudy. Will this clear with time as everything dries or should I bake the tiles to burn off the water trapped in the sealer?

- The cloudiness you see is called blushing--the remedy will depend on the finish that you used. If it a lacquer you can use blush eliminator, I have never tried it on shellac or enamel. It may go away after it is dry however. Sometimes the moisture in the air will cause the finish to blush.

- Q:What type of drill bit should I buy to cut into 4 x 4 ceramic tile on the wall? Can I place the bit into a router? The hole is 10 x 10 and I need it to be 10 1/2 x 10 1/2. There is 5/8 DW w/ metal studs behind it.

- Tile Cutting Bit

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China (Mainland) |

| Year Established | 2002 |

| Annual Output Value | US$ 50 Million - US$ 100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2008;CCC,CE |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Foshan PORT, China |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 2000 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glazed Tile CMAX-BR653

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords