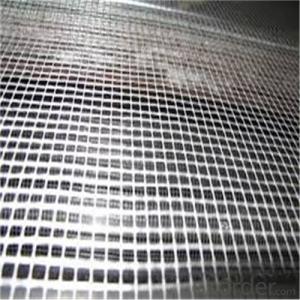

Fiberglass Mesh Roll - FRP Surfacing Mat High Quality, Low Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

It is mainly used in the surface layers of FRP products. It is characterized by uniform fiber dispersion, smooth surface, soft hand-feeling, low binder content, fast resin impregnation and good mould obedience.

This line of product falls into two categories: Wrap type \series and hand lay-up type series. The wrap type FRP surfacing mat is most suitable for wrapping FRP pipes and vessels because it is capable of significantly to improve the performances of surface layer to realize longer lifetime and resistance against corrosion leakage and compression.

The hand lay-up type FRP surfacing mat is especially suitable for molding with sophisticated contours while it is characterized by its good mould obedience and fast resin penetration. It is an indispensable material for high quality moulds and FRP products as it is capable of covering up the texture of underlayer to create high gloss surface that gives rise to improved strength and corrosion resistance. The surfacing mats in these two categories are also applicable to other FRP molding processes such as press moulding, spray-up, centrifugal rotating moulding, etc.

- Q: I'd like to have a glass fiber mesh cloth factory, but have difficulty sources of raw materials and technology, who can give some suggestions and opinions.

- If it is medium and high-grade, you must strictly control the main raw materials: warp and weft. General is the use of big company bushings drawn glass fiber yarn;

- Q: What is the difference between different glass fiber mesh cloth

- A general glass fiber mesh cloth roll at both ends, both ends of blue green is non alkali glass fiber products

- Q: What additive does alkali resistant glass fiber gridding cloth has?

- Ore melting status by purification of lower alkali content in wire drawing glass fiber grid cloth weaving to deal with

- Q: What kind of fiberglass tape do you have?

- Guangzhou Wei 1 is a professional manufacturer of fiber tape, which can be customized for customers

- Q: The difference between alkali resistant mesh cloth, emulsion and urine glue

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latexThe mesh fabric is soft and positioned, and also folded, both of which are the common products of the exterior wall insulation.

- Q: What's the mesh of glass fiber gridding cloth?

- The standard mesh specifications should include the mesh size and mesh number and they should correspond to each other. For example, 100 meshes refers to 100 meshes in each inch. Mesh size: 4.75mm Standard mesh number: 1 Mesh size: 4.00mm Standard mesh number:2 Mesh size: 3.35mm Standard mesh number: 3 Mesh size: 2.80mm Standard mesh number: 4 Mesh size: 2.36mm Standard mesh number: 5 Mesh size: 2.00mm Standard mesh number: 6 Mesh size: 1.70mm Standard mesh number:7 Mesh size: 1.40mm Standard mesh number: 8 Mesh size: 1.18mm Standard mesh number: 16 Mesh size: 1.00mm Standard mesh number:18 mesh size: 0.850mm Standard mesh number: 20 Mesh size: 0.710mm Standard mesh number: 25 Mesh size: 0.600mm Standard mesh number: 30 Mesh size: 0.500mm Standard mesh number: 35 Mesh size: 0.425mm Standard mesh number: 40 Mesh size: 0.355mm Standard mesh number: 45 Mesh size: 0.300mm Standard mesh number: 50 Mesh size: 0.250mm Standard mesh number: 60 Mesh size: 0.212mm Standard mesh number: 70 Mesh size: 0.180mm Standard mesh number: 80 Mesh size: 0.150mm Standard mesh number: 100 Mesh size: 0.125mm Standard mesh number: 120 Mesh size: 0.106mm Standard mesh number: 140 Mesh size: 0.090mm Standard mesh number: 170 Mesh size: 0.0750mm Standard mesh number: 200 Mesh size: 0.0630mm Standard mesh number: 230 Mesh size: 0.0530mm Standard mesh number: 270 Mesh size: 0.0450mm Standard mesh number: 325 Mesh size: 0.0374mm Standard mesh number: 400 A negative sign added before the mesh number refers that the mesh can leak out . For example, -100 meshes +200 meshes refers that these particles can be leaked out in 100 mesh size to 200 mesh size.

- Q: How to paste glass fiber gridding cloth on the walls?

- It is recommended to use white glue mixing with 801 glue, or batch embed glass fiber gridding cloth with some talcum powder. The price for the latter is 5 yuan/㎡.

- Q: Why is it required to wrap alkali-resistant fiberglass mesh at the entrance to the hole?

- Flanging is good for protecting the edge of insulating layer and door and window are vulnerable to external damage. The window and door openings and other locations are not the continuation of the mesh position, large wall decapitated need Internet Plaid lap, discrete locations Mesh prone to stress concentration cracks,

- Q: For fiberglass mesh in plastering inner wall, is it paved in the bottom of mortar layer or outside?

- Since it is to prevent plastering form cracking due to different stretch of wall materials, it shoulde be paved in the bottom of mortar layer.

- Q: What exactly is fiberglass mesh for?

- Often the walls of the home for a long time will appear aging, wall coating off, bald, very ugly. What's more, cracks will occur in the wall. The crack is very scary, if not treated after a considerable period of time will produce larger cracks, often a lot of damage is a wall from the start of the cracks.

Send your message to us

Fiberglass Mesh Roll - FRP Surfacing Mat High Quality, Low Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords