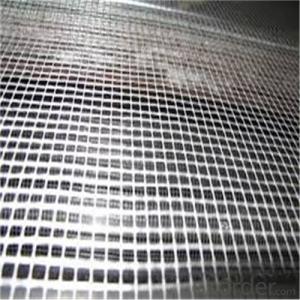

Oem Adhesive-Backed Fiberglass Mesh Cloth 145g

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass mesh is mainly alkali-resistant fiberglass fabric, it use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

Mesh size: 5mm x 5mm, 4mm x 4mm, or 4mm x 5mm

Weight/m2: 145g/m2

Length/roll: 50m-100m

Width: 1m

Color: white, blue, orange or other colors

Special spec can be ordered and produced by the requirements of customer

- Q: What do medium soft and medium hard mean in fiberglass mesh?

- The softer it is, the better material is. Fiberglass mesh is based on glass fiber woven fabric and formed by alkali-resistant coating.

- Q: Which is the best screen for polyester fiber screen window and fiberglass screen window?

- Polyester fiber advantages: strong, dry and wet, good color fastness, shrinkage stability, fabric has certain drape, as well as the general color gorgeous. Disadvantages: moisture absorption, poor ventilation

- Q: How long is a roll of mesh specially for external wall thermal insulation?

- A roll of standard alkali-resistant fiberglass mesh is 100 meters. Some mesh may be only 70 or 80 meters because the manufacturers want instant interests.

- Q: The decoration of an old house whose walls of the bedroom and living room have many cracks. Now it is intended to shovel out the wall surface before putting them on the wall mesh. Can this prevent further cracking in the future?

- Can The normal process should be dismantled - the gypsum leveling and pasting mesh - approved putty - polished painting.

- Q: What's the use of glass fiber cloth? What are the main trades?

- Building for external wall insulation layer, glass fiber industry is also useful glass fiber cloth. The main function is to increase the strength

- Q: For a woven glass fiber mesh cloth work

- It uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: How to increase the glass fiber net fabric tensile strength

- You may use clay crucibles to wire the poor fiberglass mesh fabric

- Q: What is the difference in function between alkali-resistant fiberglass mesh and hot dipping galvanized steel mesh?

- They transfer the surface load acting body. When the basis weight of fiberglass mesh increases,you must strictly control the quality of hot dipping galvanized steel to meet the stability of insulation system; the greater tensile bonding strength of brick not only protects the thermal insulation layer, but also the failure surface after drawing is concentrated on the fiberglass mesh, while having good construction operability.

- Q: What are the characteristics of the external insulation materials Mesh?

- The external wall thermal insulation Mesh (the glass fiber mesh) is with the raw material of alkali-free glass fiber, and with the glass fiber Mesh as base material, becoming a new alkali product by the coatingacrylic?acid method. The product has the characteristics of stable structure, high strength, good acid and alkali resistance, anti-corrosion, and anti-cracking ability. It has a best effect of enhancement and easy for construction. It is mainly used in cement, gypsum, walls, buildings and other structures inside and outside. It can also be used to anti-cracking, and being a new building materials of the external wall building engineering. Mesh(2 pieces) The external wall thermal insulation Mesh (the glass fiber mesh) is with the raw material of alkali-free glass fiber, and with the glass fiber Mesh as base material, then making by the acrylate copolymerization glue soluting. It has the characteristics of lightweight, high strength, temperature resistance, alkali resistance, water proofing, anti-corrosion, anti-chapping, and stable size. It can effectively avoid the crack brought by the tension contraction of the plastering layer and the external force. The thin Mesh is often used for the refurbishment of wall and the thermal insulation of the interior wall. Mesh: 5mm * 5mm, 4mm * 4mm gram weight: 80g --- 165g / m Width: 1000mm ---- 2000mm Length: 50m-300m or according to the requirements of the customer. The construction requirements of the Mesh. 1. The first floor of the word building, the doors and windows, decorative sewing, the internal and external corners, all these places should be taken to add a layer of alkali-resistant mesh cloth and wipped a cracking mortar. 2. The lap of the ordinary alkali-resistant mesh should not be less than 100mm, and the reinforced alkali-resistant mesh cloth should only be butted joint but not lapped.

- Q: What consequence will using non-alkali resistant fiberglass mesh cause in thermal insulation construction?

- Fiberglass mesh used for external wall of buildings is equivalent of soft rebarIn this application Building Exterior fiberglass mesh plays the role of soft steel construction using alkali fiberglass insulation effect did not work needs to FIG alkaline fiberglass mesh outer coating (slurry) alkali-resistant fiberglass corrosion

Send your message to us

Oem Adhesive-Backed Fiberglass Mesh Cloth 145g

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords