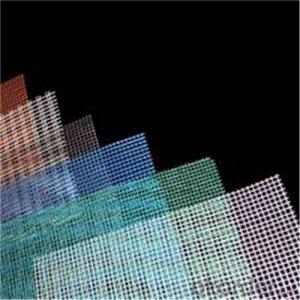

Saint Gobain Fiberglass Mesh - High Quality Fiberglass Roofing Mat at Competitive Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass tissue mat

1)Fiberglass Tissue Mat for roofing

Roofing tissue mat is mainly used as excellent substrates for waterproof roofing materials. It is characterized as high tensile strength, corrosion resistance, easy soakage by bitumen, and so on. The longitudinal strength and tear resistance can be improved further by incorporating reinforcements into the tissue across its whole width. The waterproof roofing tissue made of this substrates is not easy to crack, ageing and rot. Other advantages of waterproof roofing tissue are high strength, excellent uniformity, good weathering quality and leaking resistance.

We can produce the goods from 40gram/m2 to 100 gram /m2, and the space between yarns is 15mm or 30mm (68 TEX)

2)Fiberglass Tissue Mat for flooring

Flooring tissue mat is mainly used as substrates for plastic flooring and wall covering materials. It features in uniform thickness, dimensional stability, non-deformation and non-distortion under high temperature, resistant against mildew and easy impregnation with resin coating. The PVB cushion and vinyl flooring made from flooring mat is an ideal decorative material for floor decoration in domestic residences on account of their characteristics such as smooth appearance, non-shrinkage, non-deformation, bright color, convenient lay-up and renovation. By further processing, flooring mat can be manufactured into a variety of colourful facing materials to be used in the internal decoration in elegant hotels.

3)Fiberglass Tissue Mat for pipe wrapping

Pipe wrapping mat is used as basic material for anti-corrosion wrapping on steel pipelines that buried underground for oil or gas transportation. It is characterized by high tensile strength, good flexibility, uniform thickness, solvent -resistance, moisture resistance, and flame retardation. It is well compatible with impregnation bitumen or coal tar enamel the oil of gas pipelines wrapped by Pipe wrapping mat pre-impregnated with bitumen or coal tar enamel acquire capabilities against leakage and aggressivemedia in the environment so that the cost for maintenance and replacement can be reduced significantly and the life time of pile-line may be prolonged up to 50-60 years authoritative tests have proven that the technical target of wrapping mat series can all meet or surpass the technical specification stated in SY/T0079, the oil and gas industry standard of the people's republic of china and meet the requirement in the specification of AWWA C 203 AS WELL this mat is an ideal base material as inner wrap or outer wrap or outer wrap impregnated by bitumen of coal tar enamel

4)Fiberglass Tissue Mat for FRP surface

FRP surface mat is mainly used as the surface layers of FRP products. It is characterized by uniform fiber dispersion, smooth surface, soft hand-feeling, lowbinder content, fast resin impregnation and good mould obedience. This line of product falls into two catalogues: Filament winding type CBM series and hand lay-up type SBM series

5)Fiberglass Tissue Mat for wall covering

Wall covering mat, a environment-friendly product made of chopped fiber glass by wet process, is mainly applied for the surface layer and the inner layer of wall and ceiling with the high function of fire-retardancy, anti-corrosion, shock-resistance, anti-corrugation, crack-resistance, water-resistance, air-permeability as well as elegant and noble decorative effects. It can be widely used in public entertainment place, conference hall, star-hotel, restaurant, cinema, hospital, school, office building and resident house.,

Item | Unit | Standard Value | Actual Measured Value | |

Linear Density of reinforcement yarn | Tex | 34-68 | 68 | |

Space Between Yarn | mm | 15 | 15 | |

Area Weight | g/m2 | 50±3 | 52.3 | |

Binder Content | % | 20±2 | 20.5 | |

Tensile Strength MD | N/5cm | ≥175 | 198.8 | |

Tensile Strength CMD | N/5cm | ≥ 75 | 85.3 | |

- Q: The household is screened glass fiber gauze or stainless steel gauze.

- Instead of gauze. If the south is used to do conch door window frame, with Shide profiles north, such as the purchase of invisible screens with Aluminum Alloy profile. I hope you can help.

- Q: Who knows the practice of external wall thermal insulation mesh?

- The construction technology and practice introduction of external wall thermal insulation mesh: Production of insulation materials glass fiber mesh is based on the glass fiber woven fabric by soaking and coating the high-molecular resistant emulsion. So that there is excellent alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft, which can used for thermal insulation, waterproof and crack in the exterior and interior wall of structure. alkali-resistant glass fiber screen cloth is the major of glass fiber mesh, which is made of E-glass fiber yarn (the main elements is the silicate with chemical stubborn resistance) constructed by the extraordinary structure - leno structure woven from strangulation, and low heat sizing by the anti alkali liquid and booster. external wall thermal insulation mesh is widely used in wall reinforcement (such as fiberglass mesh wall, GRC wall panels, EPS innernal and external wall insulation, gypsum board, waterproofing roll cloth, asphaltic roofing waterproof material, fireproof?panel and building caulking belt.

- Q: Fiberglass mesh warp and weft, which one is more resistant to fracture?

- After alkaline polymer, this is not entirely the key to judging the quality of products. For the majority of consumers, quality is the most important. In order to better play the efficacy of products, it is made from middle-alkaline or non-alkialine glass fiber.

- Q: Why is the screen anti-theft screen?

- Steel net screen Fenglv aluminum material of the listed good to meet the development of the market, steel net screen market, meet a considerable part of the customers want to pack a product can achieve the anti theft and anti mosquito desire. Steel mesh screen, whether fixed on the wall or form, will have enough good endurance, not afraid of outsiders invasion. High quality steel mesh screen is all processed by electrophoresis and painting. It is not afraid of damp environment, sun burning or bad environment corrosion. Because the structure is vertically and horizontally interwoven, and the diameter of the line is also 0.8MM, the utility model not only can prevent mosquitoes from entering the room, but also can enhance the ability of prying and shearing.

- Q: Interior wall laying fiber mesh cloth, what matters should pay attention to plastering? Is it not allowed to lap when laying mesh cloth?

- Before construction, do a good job of watering walls, wet and beat, the fiber network overlap of not less than 100mm, the corner of the door should be laid, so that the grid is not exposed.

- Q: excuse me, when fixing the tile on the external wall of six-floors residential building, the thermal insulation board XPS extruded polystyrene board is using the steel mesh or the glass?fiber mesh.

- Both are currently in use, the majority is steel wire, preferably with reference to the implementation of local policies or standards.

- Q: When mineral varnish finishing is used for external wall thermal insulation, can fiberglass mesh be used?

- It is no problem.

- Q: What is the difference between the glass fiber mesh fabric with inner and outer wall insulation?

- In winter, when the indoor heat through the wall insulation material is Chinese cloth will be cut off so as to be preserved, and when the indoor temperature down. The wall of the heat will be released, by adjusting the indoor temperature; in the summer, the glass fiber cloth Chinese insulation will prevent radiation from the sun and is communicated with the external heat into the room, so that the indoor situation of "cool", and the ten seasons and pleasant residential Polygonatum and physical skills improved significantly

- Q: What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- As for the cloth and mesh cloth, just different weave, has nothing to do with the glass composition.

- Q: How to produce mesh?

- With medium-alkaline or non-alkaline glass fiber yarn as raw materials and woven fiberglass mesh as base material, external wall thermal insulation mesh is a new alkali resistant product after coated with acrylic copolymer solution. With medium-alkaline or non-alkaline fiberglass mesh as base materials, internal wall thermal insulation alkali resistant fiberglass mesh is formed by being coated with modified acrylate copolymer adhesive solution.

Send your message to us

Saint Gobain Fiberglass Mesh - High Quality Fiberglass Roofing Mat at Competitive Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords