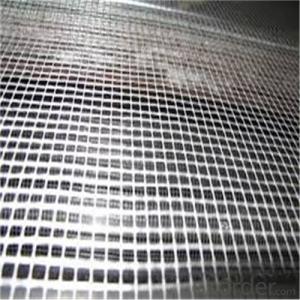

Woven Fiberglass Mesh - Core Mat High Quality & Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORE MAT

PRODUCT DESCRIPTION

CORE MAT is a stratified reinforcing glass fiber fabric composed by 5 layers. 2 exterior layers of random mat, 1 layer of woven roving and 2 layers of synthetic fibers. The main application is for RTM and RTM Light parts where mechanical performance is a must.

CONSTRUCTION

CORE MAT has been manufactured by stitch bonding technology. The 5 layers are arranged as follows:

Layer 1: Random glass fiber mat

Layer 2: Synthetic Web

Layer 3: Woven roving

Layer 4: Synthetic Web

Layer 5: Random glass fiber mat

The layers 2 and 4 are made by a synthetic material (polypropylene)and the main purpose of these layers is to allow the resin flow and provide compressibility to the reinforcement.

STYLES

The standard materials are the ones in the following list, but other designs are also available according to customer needs

Specification Glass fiber G/M2 Total dry weight G/M2

250BWR500B250 1000 1250

350BWR500B350 1200 1450

450BWR500B450 1400 1650

250BWR800B250 1300 1550

350BWR800B350 1500 1750

450BWR800B450 1700 1950

How to understand CORE MAT description:

Example:

250BWR500B250

- Q: What is the function of the cracking resistant mortar Mesh?

- The Mesh is a material for insulation which can resist crack. The cracking resistant mortar is an antimitotic agent made up of by polymer emulsion and admixture. The cement and the sand mixed together according to a certain proportion can become the mortar that can make a certain deformation and resist cracking. It is mainly used for the thermal insulation of the external wall or the thermal insulation of the interial wall, the external cover of polyphenyl board and extruded sheet.

- Q: What CE certification should glass fiber gridding cloth be done?

- CE certification is a kind of safety certification and regarded as a pass of manufacturer to Europe market.

- Q: The difference between glass fiber and plastic fiber screen

- You say that the chemical fiber adsorption should refer to electrostatic adsorption, rather than activated carbon adsorption! The chemical fiber filter screen has no adsorption to the odor! The fiber diameter and pore size of the glass fiber filter screen are much smaller than that of the chemical fiber! The two can produce bacteria, but the bacteria in the fiberglass can not pass through the screen (the bacteria on the wind side can fly out, but they will also be blocked on the screen later).

- Q: What are the main applications of fiberglass mesh?

- Wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on

- Q: What are the hazards of glass fiber to human body?

- Glass fiber workers have contact dermatitis, but some workers can gradually tolerate, known as "sclerosis.". The extent of skin damage depends on fiber diameter and surface roughness. It is now accepted that fiber diameter exceeds 5 mu m, which has a significant stimulating effect. A small number of people exposed to glass fiber and rock wool have skin allergies, but so far they have not been proved to be allergens.

- Q: The hardware cloth and the Mesh, which is better for the the thermal insulation ?

- The Mesh is not suitable for the thermal insulation of the external wall. The Mesh and metal net are used in the different medium wall(the concrete structure, the red brick, the joint of the masonry bricks) to prevent cracking in steel mesh insulation mortar to do with the grass roots contact, to prevent the shedding of the mortar because it's too thick. The general mesh is convenient to the construction. And the weight is light, and the price is cheap. There is no need to drive nail and it can be pasted directly with the glue. The pasting speed is fast but sometimes cannot be binding well and separate from the hardware cloth easily. It is with a high price but has a little difficulties in construction. And the waterproof mortar will have water leakage. It is easy to be corroded, and the polluted wall often uses the mesh.

- Q: What is the specification of external wall thermal insulation mesh

- The interior wall mesh is made of glass fiber as the main raw material, but also through the multi-channel processes. The interior wall mesh is ideal material for grc wallboard. The unit weight of interior wall thermal insulation mesh is generally lighter about 50-60 grams and the quality tensile strength is relatively small. The exterior wall thermal insulation mesh is typically 80-160 grams, depending on the different buildings, which used in the external walls better with a tensile strength.

- Q: excuse me, when fixing the tile on the external wall of six-floors residential building, the thermal insulation board XPS extruded polystyrene board is using the steel mesh or the glass?fiber mesh.

- it is good to the whole system security and the drawing resistance test of tiles and it should strengthen the XPS plastering mortar and the XPS bond then paste the tile. Using anchor bolt to fix the steel mesh and then paste tiles, then you can carry the force of the anchor to the base wall, a portion of the additional shear and I suggest taking the method of anchor bolt expansion steel mesh.

- Q: The advantages of alkali-resistant glass fiber mesh cloth

- Alkali-resistant fiberglass mesh is softer, so it just disperse the deformation stress (deformation stress beyond deformation temperature ), but unable to share the tension of adhesive layers. When the basis weight of fiberglass mesh increases, the greater the tensile bond strength of brick, but the increase is not obvious.

- Q: What is fiberglass strainer?

- Glass fiber screen is mainly used in industrial clean room, chip workshop, operation room, high-end purifier and high-end fresh air system.

Send your message to us

Woven Fiberglass Mesh - Core Mat High Quality & Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords