Lowes Fiberglass Mesh - Core Mat Quality and Lowest Price from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

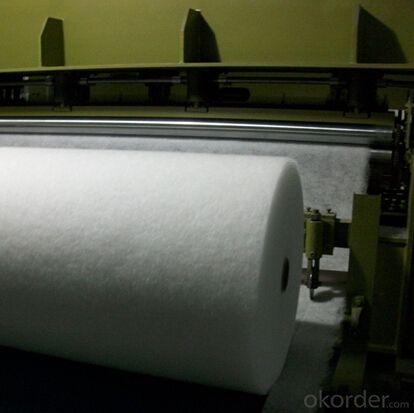

CORE MAT

PRODUCT DESCRIPTION

CORE MAT is a stratified reinforcing glass fiber fabric composed by 5 layers. 2 exterior layers of random mat, 1 layer of woven roving and 2 layers of synthetic fibers. The main application is for RTM and RTM Light parts where mechanical performance is a must.

CONSTRUCTION

CORE MAT has been manufactured by stitch bonding technology. The 5 layers are arranged as follows:

Layer 1: Random glass fiber mat

Layer 2: Synthetic Web

Layer 3: Woven roving

Layer 4: Synthetic Web

Layer 5: Random glass fiber mat

The layers 2 and 4 are made by a synthetic material (polypropylene)and the main purpose of these layers is to allow the resin flow and provide compressibility to the reinforcement.

STYLES

The standard materials are the ones in the following list, but other designs are also available according to customer needs

Specification Glass fiber G/M2 Total dry weight G/M2

250BWR500B250 1000 1250

350BWR500B350 1200 1450

450BWR500B450 1400 1650

250BWR800B250 1300 1550

350BWR800B350 1500 1750

450BWR800B450 1700 1950

How to understand CORE MAT description:

Example:

250BWR500B250

- Q: How to choose glass fiber filter cartridge

- In addition you need to know about the properties of ultrafine dust: dust, wet dust or ordinary dust, flammable and explosive dust filter, I set well then you decided to fold the cartridge or the number of effective filtration area, which will determine the volume of the filter cartridge and the dust collector is the air, otherwise the dust removal effect either good or no dust collector cartridge life short.

- Q: When the outer insulation lacquer decorative glass fiber cloth can do it

- Can not even produce tiny cracks cause surface cracking phenomenon of stress using the grid cloth to prevent precausions mortar contraction.

- Q: What are the bonding requirements of alkali resistant fiberglass mesh? Anti cracking protection layer construction, alkali resistant fiberglass mesh cloth why not dry lap?

- The alkali resistant fiberglass mesh cut edges cut, the length of not more than 3m, with mortar on a thermal insulation layer, the thickness control in 3-5mm, immediately wipe the alkali resistant fiberglass mesh with iron containing zirconium glass fiber mesh to the substrate, coated alkali resistant rubber material, is the anti crack protective layer supporting products.

- Q: What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q: What's the use of gridding cloth pasted on the wall?

- The measures that taken for preventing the cracks after plastering, are used for prevent the cracks/ Now the masonry materials mainly include filling block.

- Q: Is there a difference between a textile knife and a chemical fiber knife and a fiberglass cutter?

- Chemical fiber is made of natural macromolecule compound or synthetic macromolecule compound, which is prepared by spinning, dope, spinning and post-treatment.

- Q: Balcony gauze nets, in the end to buy glass fiber yarn net or 304 stainless steel yarn net?. What are the advantages?

- Of course is a good cheap stainless steel screens and only a few yuan, exposed to the weather not easily broken, good cleaning, side toward the outside is an untouchable, in face of no breakage is not a bit difficult to handle, you can use a dozen or even dozens of years. Fire prevention, rats, bites, etc.Plastic, glass fiber, window screening and so on, even if cheap, every 1-2 years to replace costs and raw materials on the high, but also trouble. For example: even if raw material per square metre 1 yuan, change 10 times raw material is 10 yuan, still do not calculate labor cost.

- Q: Fiberglass mesh reinforced waterproof roll is via the texture of the tire to distinguish the waterproof quality. General polyester tire is better than fiberglass tire in quality.

- PE polyethylene film, varieties The coiled material uses two sub tread mark?number: glass fiber felt or polyester felt. The nominal weight of coiled material... What kind of SBS shoule be taken?

- Q: The advantages of alkali-resistant glass fiber mesh cloth

- Alkali-resistant fiberglass mesh is softer, so it just disperse the deformation stress (deformation stress beyond deformation temperature ), but unable to share the tension of adhesive layers. When the basis weight of fiberglass mesh increases, the greater the tensile bond strength of brick, but the increase is not obvious.

- Q: Does anybody know whether carbon fiber grid is the same as carbon fiber mesh?

- They are the same product, but just names are different.

Send your message to us

Lowes Fiberglass Mesh - Core Mat Quality and Lowest Price from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords