Chopped Fiberglass Strands 1 Fiberglass Powder Chopped Stand Mat General Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Technique: | Chopped Strand Fiberglass Mat (CSM) | Dimensions: | 450gsm | Mat Type: | Continuous Filament Mat |

| Fiberglass Type: | E-Glass | Softness: | softness | Place of Origin: | Jiangxi, China (Mainland) |

| Brand Name: | cnbm | Model Number: | 450gsm | color: | white |

| fiberglass type: | E glass | product: | e-glass powder chopped stand mats | binder: | powder or emulsion |

| width: | 1040 or 1270mm, as your requirement | weight: | 30 or 45kg/roll | paper tube diameter: | 90mm |

| outer diameter of roll: | 256mm | packing: | plastic film+carton box + pallet |

Packaging & Delivery

| Packaging Details: | plastic film+carton box + pallet |

| Delivery Detail: | 15-20days |

Specifications

1.e-glass powder chopped stand mats

2.binder:power or emulsion

3.width:1040mm or 1270mm

4.weight:450gsm

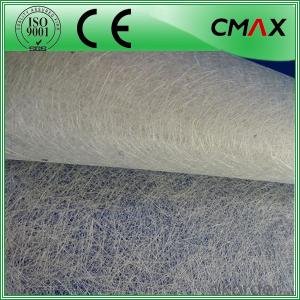

Picture

- Q: Does fiberglass chopped strand improve the weathering resistance of composite materials?

- Yes, fiberglass chopped strand does improve the weathering resistance of composite materials. The addition of fiberglass chopped strand enhances the overall durability and resistance of the composite to various weathering conditions such as UV radiation, moisture, and temperature fluctuations. This reinforcement helps to prevent degradation and maintain the structural integrity of the composite material over time.

- Q: Can fiberglass chopped strand be used in roofing materials?

- Yes, fiberglass chopped strand can be used in roofing materials. It is commonly used as a reinforcement material in roofing shingles and sheets due to its high strength, durability, and resistance to weathering and UV rays.

- Q: What are the cost considerations when using fiberglass chopped strand?

- There are various cost considerations that must be taken into account when utilizing fiberglass chopped strand. Initially, one should consider the cost of the fiberglass chopped strand itself. This cost can fluctuate depending on the quality and type of fiberglass employed. While higher quality fiberglass may be pricier, it can also offer superior performance and longevity. In addition to the material cost, there are other factors to ponder. The expenses associated with transportation and handling should be factored in, as fiberglass chopped strand can be bulky and require delicate handling during transit. This can increase the overall cost, particularly if the material needs to be shipped over long distances. Moreover, the cost of processing the fiberglass chopped strand should be considered. This encompasses any cutting, shaping, or molding that needs to be executed on the material. Depending on the intricacy of the project and the equipment required, this can augment the overall cost. It is also crucial to contemplate the cost of any supplementary materials or components that may be necessary when utilizing fiberglass chopped strand. For instance, if the fiberglass is being incorporated into a composite material, the cost of the resin, additives, and other reinforcing materials should be factored into the equation. Lastly, the cost of labor should not be overlooked. If specialized skills or equipment are required to work with fiberglass chopped strand, additional labor costs may be incurred. This might encompass the cost of training or hiring skilled workers, as well as any extra time needed for the fabrication or installation process. All in all, when employing fiberglass chopped strand, it is vital to consider the cost of the material itself, transportation and handling, processing, additional materials, and labor. By thoroughly evaluating these cost considerations, one can make well-informed decisions to ensure the most cost-effective utilization of fiberglass chopped strand.

- Q: What are the typical creep properties of fiberglass chopped strand composites?

- The typical creep properties of fiberglass chopped strand composites refer to the material's tendency to deform and relax under a constant load or stress over an extended period of time. Fiberglass chopped strand composites exhibit relatively low creep compared to other materials such as metals or polymers. This is due to the reinforcing properties of the fiberglass strands, which provide strength and stiffness to the composite. Creep in fiberglass chopped strand composites is influenced by various factors, including temperature, humidity, and the applied load. At higher temperatures, the creep rate tends to increase as the matrix material softens, allowing for more deformation. Similarly, high humidity levels can accelerate creep as moisture can weaken the matrix and reduce the overall strength of the composite. The applied load or stress level also affects the creep behavior of fiberglass chopped strand composites. Higher loads typically lead to higher creep rates, as the material experiences greater deformation under the sustained stress. However, the reinforcing nature of the fiberglass strands helps mitigate creep by distributing the load and preventing localized deformations. Overall, fiberglass chopped strand composites exhibit relatively low creep properties, making them suitable for applications that require dimensional stability and resistance to prolonged stress. However, it is important to consider the specific environmental conditions and load requirements to ensure the material's performance meets the desired expectations.

- Q: How does the fiber orientation affect the impact resistance of fiberglass chopped strand composites?

- The fiber orientation significantly influences the impact resistance of fiberglass chopped strand composites. When the fibers are aligned in the direction of impact, they can effectively distribute and absorb the applied load, resulting in improved impact resistance. Conversely, if the fibers are randomly oriented or misaligned, the load distribution is less efficient, leading to reduced impact resistance. Therefore, proper fiber orientation plays a critical role in enhancing the impact resistance of fiberglass chopped strand composites.

- Q: Is fiberglass chopped strand resistant to heat?

- Generally, fiberglass chopped strand exhibits resistance to heat. It is composed of glass fibers and a thermosetting resin, typically polyester or epoxy. These constituents possess a high melting point and can endure elevated temperatures without melting or distorting. Nevertheless, it is crucial to acknowledge that the heat resistance of fiberglass may fluctuate depending on the particular type and composition of the material. Certain fiberglass items are engineered to withstand higher temperatures compared to others. It is highly advised to consult the manufacturer's specifications and guidelines for the particular fiberglass chopped strand product to ascertain its heat resistance capabilities.

- Q: Can fiberglass chopped strand be used in the production of insulation blankets?

- Yes, fiberglass chopped strand can be used in the production of insulation blankets. Fiberglass chopped strand is a lightweight and versatile material that offers excellent thermal insulation properties. It can be easily processed and formed into insulation blankets, which are widely used in various industries for thermal and acoustic insulation purposes. The chopped strands help to enhance the overall insulation performance of the blankets by providing a dense and uniform layer of insulation material. Additionally, fiberglass chopped strand is resistant to moisture, chemicals, and fire, making it an ideal choice for insulation applications.

- Q: Is fiberglass chopped strand compatible with different curing methods?

- Yes, fiberglass chopped strand is compatible with different curing methods. It can be cured using various methods such as heat curing, chemical curing, and ultraviolet (UV) light curing, depending on the specific application and requirements.

- Q: What are the thermal expansion properties of fiberglass chopped strand?

- Fiberglass chopped strand exhibits certain thermal expansion properties. When exposed to heat, fiberglass chopped strand tends to expand. The degree of expansion depends on various factors such as the composition of the fiberglass, the temperature range, and the length of the chopped strand. Generally, fiberglass chopped strand has a relatively low coefficient of thermal expansion. This means that it expands at a slower rate compared to other materials when subjected to temperature changes. The low coefficient of thermal expansion makes fiberglass chopped strand an ideal material for applications where dimensional stability is crucial, such as in the construction of composite materials, thermal insulations, and automotive components. However, it is important to note that the specific thermal expansion properties may vary depending on the manufacturer and the specific product formulation. Therefore, it is recommended to consult the manufacturer's technical data sheet or conduct tests to determine the exact thermal expansion properties of a particular fiberglass chopped strand product.

- Q: How does the fiber orientation distribution of fiberglass chopped strand affect the properties of composites?

- The fiber orientation distribution of fiberglass chopped strand plays a significant role in determining the mechanical properties of composites. The alignment and distribution of fibers within the composite affect its strength, stiffness, and overall performance. A well-aligned and uniform fiber orientation leads to improved tensile and flexural strength, as well as enhanced resistance to impact and fatigue. On the other hand, a random or uneven fiber distribution may result in weaker mechanical properties and reduced overall structural integrity. Therefore, controlling and optimizing the fiber orientation distribution is crucial in achieving desired properties in fiberglass-chopped strand composites.

Send your message to us

Chopped Fiberglass Strands 1 Fiberglass Powder Chopped Stand Mat General Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords