Fiberglass Mat Tissue Chopped Strand Mat Emulsion Powder Glass Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Powder and Emulsion Fiberglass Glass Fiber Chopped Strand Mat

Introduction:

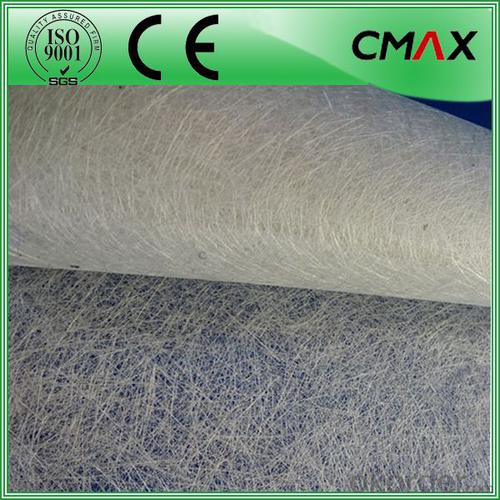

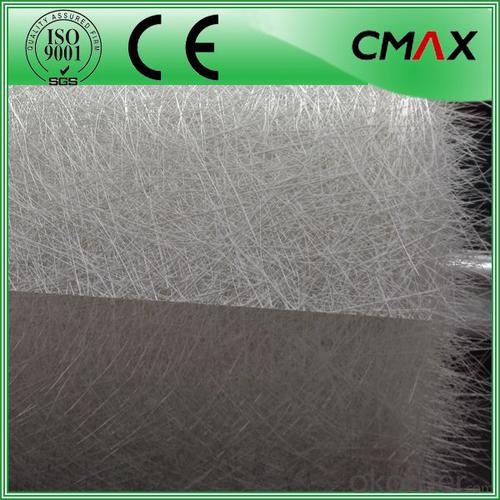

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

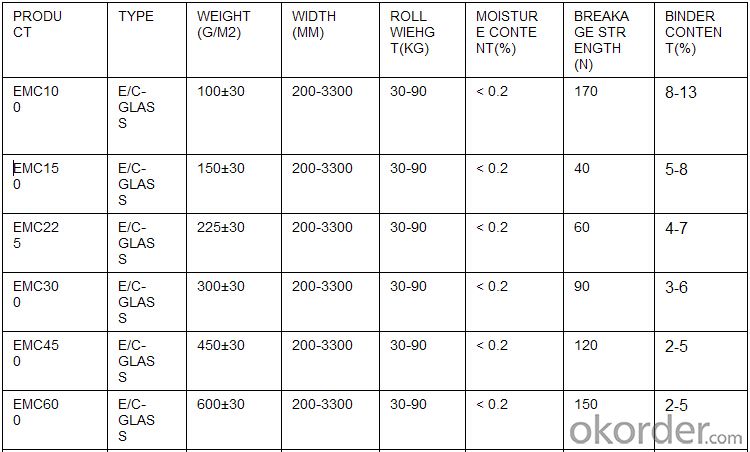

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for corrosion-resistant applications?

- Yes, fiberglass mat tissue can be used for corrosion-resistant applications. It is commonly used as a reinforcement material in composite products that require resistance to corrosion, such as pipes, tanks, and structural components in harsh environments. The fiberglass mat tissue provides strength and durability while also enhancing the corrosion resistance properties of the final product.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally has good UV resistance. UV resistance refers to the ability of a material to withstand the harmful effects of ultraviolet radiation from the sun without degrading or deteriorating. Fiberglass mat tissue is usually manufactured using a combination of fiberglass and a binder material, which provides strength and integrity to the tissue. The fiberglass component in the mat tissue provides inherent UV resistance. Fiberglass is known for its durability and ability to resist degradation from UV exposure. It is a non-porous material that does not absorb UV radiation, making it less susceptible to damage caused by the sun's rays. Additionally, some manufacturers may apply a UV-resistant coating or treatment to the fiberglass mat tissue to enhance its UV resistance. This coating or treatment can further protect the tissue from the damaging effects of prolonged exposure to UV radiation. Overall, fiberglass mat tissue performs well in terms of UV resistance. It is a durable material that can withstand the harmful effects of UV radiation, making it suitable for applications where prolonged exposure to sunlight is expected. However, it is important to note that the specific UV resistance of fiberglass mat tissue may vary depending on the manufacturing process, quality of materials used, and any additional coatings or treatments applied.

- Q: Can fiberglass mat tissue be used for making lightweight panels?

- Yes, fiberglass mat tissue can be used for making lightweight panels. It is often used as a reinforcement material in composite panels, providing strength and durability while keeping the overall weight of the panels low.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- Generally, fiberglass mat tissue is not utilized for HVAC insulation. The insulation used in HVAC systems typically necessitates materials that are purposely engineered to possess significant thermal resistance and inhibit the transmission of heat or cold air. Fiberglass mat tissue is frequently employed as a reinforcing material in the construction of composite materials, such as fiberglass panels or structures, rather than for insulation purposes. Insulation materials intended for HVAC systems are commonly composed of materials such as fiberglass insulation boards, foam insulation, or mineral wool, which possess superior thermal resistance properties and are specifically tailored for HVAC applications.

- Q: Is fiberglass mat tissue suitable for insulation in sports facilities?

- Yes, fiberglass mat tissue is suitable for insulation in sports facilities. It is a commonly used material for insulation due to its excellent thermal insulation properties, durability, and resistance to moisture. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a practical choice for sports facilities where energy efficiency and temperature control are important factors.

- Q: Can fiberglass mat tissue be used for insulation in commercial buildings?

- Yes, fiberglass mat tissue can be used for insulation in commercial buildings. It is a common and effective insulation material that provides thermal insulation, soundproofing, and fire resistance properties. It is often used in commercial buildings to improve energy efficiency and create a comfortable indoor environment.

- Q: What is fiberglass mat tissue made of?

- Fiberglass mat tissue is made of fine strands of glass fibers that are woven together to form a thin, flexible fabric-like material. These glass fibers are typically made from molten glass that is drawn into very thin filaments and then coated with a binding agent to improve strength and durability. The woven structure of the fiberglass mat tissue helps to provide reinforcement and stability to various materials and products, making it an ideal choice for applications such as insulation, roofing, and composite materials.

- Q: Is fiberglass mat tissue compatible with different adhesives?

- Yes, fiberglass mat tissue is compatible with different adhesives. Fiberglass mat tissue is a versatile material that can be used in various applications such as construction, automotive, and aerospace industries. It is commonly used as a reinforcement material in composites, where it is combined with resin and adhesive to create strong and durable structures. The compatibility of fiberglass mat tissue with different adhesives depends on several factors such as the type of adhesive, the specific application, and the desired performance requirements. Fiberglass mat tissue can be compatible with a wide range of adhesives including epoxy, polyester, vinyl ester, and polyurethane adhesives. It is important to consider the specific properties and characteristics of the adhesive and the fiberglass mat tissue when selecting the adhesive for a particular application. Factors such as curing time, viscosity, bond strength, and chemical resistance should be taken into account to ensure optimal adhesion and performance. In some cases, surface treatment or priming may be necessary to enhance the compatibility between the fiberglass mat tissue and the adhesive. This can involve applying a primer or using a specific surface treatment method to promote adhesion and ensure a strong bond between the two materials. Overall, fiberglass mat tissue is compatible with different adhesives, but it is crucial to consider the specific requirements of the application and select the appropriate adhesive and surface treatment method to achieve the desired results.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units.

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Yes, fiberglass mat tissue usually requires surface preparation before application. This may include cleaning the surface, removing any loose particles, and ensuring it is dry and free from any contaminants. Proper surface preparation helps to ensure good adhesion and a successful application of fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat Emulsion Powder Glass Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords