Fiber Cement board for villas,high building-016

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

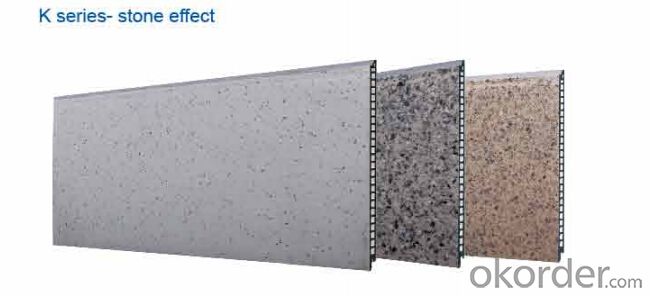

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

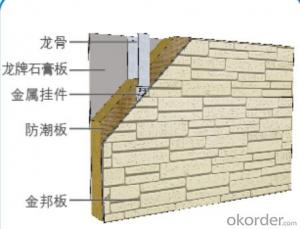

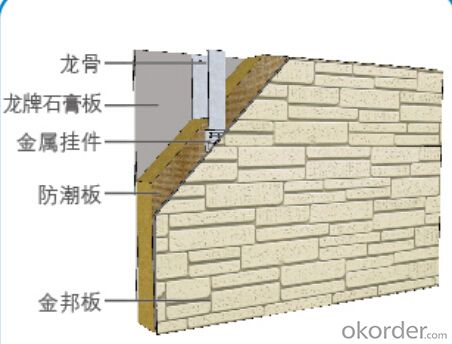

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: How to solve the old concrete and the new pouring between the concrete does not leak it?

- As for the old and new concrete joints are leaked, it seems not an important issue, because it is not the roof, in the wall after the concrete window is in the interior, but also to install the above wood floor, there is no water leakage, Do a good job, strong bonding between old and new concrete is necessary. For your small project, the old concrete surface cut (with a sharp hammer knocked on the surface layer can be), and then clean the surface dust, you can ensure that the old and new concrete good bond.

- Q: Bathroom with cement board hanging the top, now open the hole to install the lights, so hard to open Oh ,,, which big god to help me out of ideas? Thank you!

- With the impact drill easy to break the tiles, you can go to the decorative supplies store to buy a drill bit of glass drill, very good, the effect is very good.

- Q: Can the cement do not dry?

- After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board.

- Q: How to apply waterproof material on the cement board?

- You can first brush again JS composite flexible waterproof coating, and then brush it again K11 waterproof coating paint; or brush twice straight JS composite elastic waterproof coating, so you can have a good crack resistance.

- Q: the post box had 2 -2x6 boards somehow attached to the cement. The boards rotted out and fell over in a windstorm. I'd like to attach a 4x4 post bracket on the cement, then put a pressure treated 4x4 post for the mailbox. I think I need to get the bracket fixed so it's level before I drill into the cement. would I use an epoxy glue to do this?

- Some knucklehead clobbered my mailbox and sheared the wooden post right at the surface of the sidewalk. The homeowner's association fixed it by anchoring 2 L-brackets onto the sidewalk and fastened a new mailbox post right above the stump of the old post.

- Q: almost finished with tiling on cement board wall. ran into problem with corner applying bull nose piece.?

- Use Hardibacker and seal the seams with tape and thinset. Use thinset to set the tile employing a million/4 spacers. I even have used and advise which you utilize a tile sealer to seal the slate previous to grouting and to apply epoxy grout. The grout is extra durable to place in yet demands no sealers that would desire to be redone a minimum of as quickly as a 365 days in a bath and is definitely truly actual worth the preliminary time and attempt. be effective to make sure and follow the instructions on the grout bags to make particular a uniform colour and powerful grout set. MT C

- Q: Gypsm plaster is recommended in Christopher Alexander's Pattern Language (#235 Soft Inside Walls) If I were to go to a building supply store and ask for gypsum plaster would they know what I was talking about? ...Is it a universal term? Can you give me a chemical formula?

- Gypsm is hydradated pulverized limestone. You would ask for Gypsym topcoat or Gypsm tape adhesive in the Drywall department of Lowes. It costs today $9.95 for a 5 gallon pail of the stuff. Gypsm is resoluable in water after drying. In other words you can redissolve gypsm in water. Gypsm is mined in the US in states like Michigan, Indiana, Ohio and so on. It is a naturally occuring substance. Plaster of Paris is unhydrated form of lime. When wetted with water it changes chemically and remains hard no matter if submerged into water. The process is irreversible. Cement is made from clay and limestone fired to high temperatures, then ground and pulverized. When water is added to cement it changes its chemistry and the water reacts with cement forming a new compound It is irreversible The Romans invented Cement. Common Drywall is gypsm between 2 layers of paper enclosure. There are also metal lath in 26x84 inch lenghts and plaster board lath in 16x36 inch lengths Those all above are nailed or glued to the house studs.

- Q: am Laying Floor Tile and was Wondering if the Mesh Tape for Cement Board is the Same as you use for Drywall?

- It's similar, but wider. Hope this helps.

- Q: I need to raise a bathroom floor about 3/4 inch. I have already poured a thin layer of self leveling concrete over what appeared to be some sort of concrete floor that had some uneven areas (60 year old house). I have read about how you are not supposed to put backer board on concrete because you can't secure it. My question is this: could you lay the backer board on top of the SLC, leave some small gaps between the boards, and then pour another layer of SLC on top of the backer board, thereby cementing it into place??

- I d rather see you pore a SLC to the depth you need it.. Some compounds you can pore to the depth of 1 in 1 pore and some you need to do in 2 pores. Now if you need to do a full 3/4 depth you can do a tile mud bed , but this is a little challenging for a 1 st time. If you have some good DIY skills then you can probably do it. Just going over slab requires a few different steps when doing a mud bed over slab. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Can the cement board cut off the wall directly

- Mud wall can not be directly painted, need to do something to deal with, as follows: grass-roots treatment, the new cement mortar wall should not brush paint, the general need to wait six months after the oil. If you must paint, can be washed every 2 to 3 days a time to wash the wall, repeated many times. Brush oil before, but also the application of 10 to 20% of the dilute hydrochloric acid water coated once to neutralize the cement mortar in the remaining alkali, to be a moment after the water to wash the acid water, dry. So that the new cement mortar surface layer will not appear after the paint color, loss of light, from the volume of the phenomenon. Old cement mortar wall is best to use pig water and water into rice soup-like, with rows of rituals in the cement mortar wall full brush once, dry and then full of pig blood putty. General cement mortar wall paint before the surface to remove the dust clean, with plaster putty cracks, depression and other injuries filled. Paint is also a very critical step, the general wall can be twice brushing enamel, the second time to wait for the first pass and then brush. Oil brush in the brush when the direction of movement should be about to brush down, so brush evenly, the connector is not easy to see.

Send your message to us

Fiber Cement board for villas,high building-016

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords