EPDM Waterproof Membrane for Roofing Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

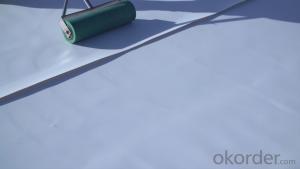

Description Of EPDM Waterproof Membrane for Roofing Market:

--EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

--EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

--EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Membrane for Roofing Market:

--Excellent physical and mechanical performance

--High tearing resistance

--Good deformation adaptability

--High puncture resistance

--High aging resistance

--UV resistance

Application of EPDM Waterproof Membrane for Roofing Market:

--Roofs, Basement, Toilet

--Industrial and civil building waterproofing

--Geo-synthetic liner for swimming pool, channels, irrigation system

--Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Technical Parameters of EPDM Waterproof Membrane for Roofing Market:

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. What is your main market?

Our EPDM Waterproof Membrane for Roofing Industry sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

3. What is your advantage for EPDM Waterproof Membrane for Roofing Industry ?

With the most advanced production line, our good quality is based on superior material imported from America.

- Q: Can a waterproofing membrane be used on plywood?

- Yes, a waterproofing membrane can be used on plywood. Plywood is a commonly used material in construction and is often used as a subfloor or as a base for various types of flooring. However, plywood is not naturally waterproof and can be susceptible to damage from moisture. To protect plywood from water damage, a waterproofing membrane can be applied to the surface. These membranes are designed to create a barrier that prevents water from penetrating the plywood, keeping it dry and preventing rot or mold growth. Waterproofing membranes can be used in various applications such as bathrooms, kitchens, decks, and roofs. It is important to choose a waterproofing membrane that is suitable for plywood and to follow the manufacturer's instructions for proper installation to ensure the best results.

- Q: Can a waterproofing membrane be used on steel surfaces?

- Indeed, steel surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically designed to establish a shield against moisture and water incursion, and they possess the versatility to be utilized on a range of surfaces, including steel. Construction endeavors, including roofs, balconies, and foundations, frequently feature steel surfaces. By employing a waterproofing membrane on these steel surfaces, one can effectively thwart corrosion and harm arising from water contact. It is crucial to carefully choose a waterproofing membrane that suits steel surfaces, while also adhering to correct surface preparation and application techniques to attain maximum performance and longevity.

- Q: Does a waterproofing membrane provide any insulation benefits?

- No, a waterproofing membrane does not provide any insulation benefits. The primary purpose of a waterproofing membrane is to protect the underlying structure from water damage by preventing water from penetrating through the surface. It acts as a barrier to keep water out and maintain the integrity of the structure. Insulation, on the other hand, is designed to regulate temperature and prevent heat transfer. It helps to maintain a comfortable indoor environment by reducing the transfer of heat between the interior and exterior of a building. Insulation materials are typically installed within the walls, floors, or roofs to provide thermal resistance and improve energy efficiency. While both waterproofing and insulation contribute to the overall performance and durability of a building, they serve different purposes. Waterproofing focuses on keeping water out, while insulation focuses on regulating temperature. Therefore, it is important to use both waterproofing and insulation materials in appropriate areas to ensure the best results.

- Q: Can a waterproofing membrane be used for an industrial facility?

- An industrial facility can utilize a waterproofing membrane. Such a membrane is a layer of protection that is applied to surfaces in order to prevent water from penetrating and causing moisture damage. Industrial facilities, including manufacturing plants, warehouses, and processing plants, often require effective waterproofing to safeguard their structures, equipment, and inventory against water damage. Industrial facilities commonly face exposure to various water sources, such as rain, leaks, or spills. Additionally, these facilities may experience high humidity levels or engage in water-intensive processes. By using waterproofing membranes, a reliable barrier against water intrusion can be established, thereby preventing damage and corrosion to the facility's structure, machinery, and products. Waterproofing membranes are designed to be durable and long-lasting, capable of withstanding harsh industrial conditions and heavy traffic or equipment. They come in different materials, such as bitumen, PVC, EPDM, or polyurethane, providing flexibility in selecting the most appropriate membrane for specific industrial applications. Moreover, waterproofing membranes offer additional advantages beyond water resistance. Certain membranes possess insulation properties, aiding in temperature regulation and reducing energy consumption. They can also enhance the overall safety and hygiene of an industrial facility by inhibiting the growth of mold, mildew, or bacteria that thrive in damp environments. To conclude, the utilization of a waterproofing membrane can prove highly effective in safeguarding an industrial facility from water damage. It establishes a dependable barrier against water intrusion, ensuring the facility's longevity and functionality while protecting valuable assets within it.

- Q: Is a waterproofing membrane resistant to solvents or chemical spills?

- Yes, a waterproofing membrane is typically resistant to solvents or chemical spills.

- Q: Are waterproofing membranes suitable for commercial applications?

- Indeed, waterproofing membranes prove to be a fitting choice for commercial applications. Specifically designed to safeguard buildings, structures, and surfaces from water infiltration, moisture damage, and similar issues, waterproofing membranes are frequently employed in diverse commercial scenarios such as roofs, basements, underground parking garages, and exterior walls. Commercial structures face a wide array of weather conditions and water sources, encompassing rainfall, snowfall, and groundwater. Waterproofing membranes serve as a dependable barrier, effectively preventing water penetration and averting costly water-related harm. Furthermore, they serve as a vapor barrier, mitigating moisture accumulation and condensation within the building envelope, which may otherwise lead to mold growth and structural decay. Waterproofing membranes are obtainable in various materials including bitumen, modified bitumen, EPDM, PVC, and TPO. Each material boasts distinct advantages and characteristics, allowing for flexibility in choosing the most appropriate option for specific commercial applications. They can be applied as liquid coatings, sheets, or panels, providing versatility in terms of installation methods to accommodate diverse building designs and requirements. Moreover, waterproofing membranes can be tailored to cater to specific commercial needs such as fire resistance, UV protection, and durability. This renders them highly effective in safeguarding commercial properties that may be subjected to heavy foot traffic, mechanical equipment, or other potential sources of damage. To summarize, waterproofing membranes prove to be an exceptionally suitable solution for commercial applications. They offer reliable protection against water infiltration, moisture damage, and related issues, ensuring the longevity and structural soundness of commercial buildings. Their versatility, customizable options, and ability to withstand various weather conditions make them an outstanding choice for commercial waterproofing requirements.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can waterproofing membranes be used on metal roofs?

- Yes, waterproofing membranes can be used on metal roofs. Waterproofing membranes are a popular choice for protecting and sealing roofs, including metal roofs. These membranes are designed to provide a barrier against water penetration, protecting the roof structure and preventing leaks. They can be applied directly to the metal roof surface, creating a watertight seal that is resistant to moisture, UV rays, and other environmental factors. Waterproofing membranes can effectively extend the lifespan of metal roofs by preventing rust and corrosion, while also improving energy efficiency by reducing heat transfer. Therefore, using waterproofing membranes on metal roofs is a viable and effective solution for ensuring durability and longevity.

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to ensure that the manufacturer's instructions are followed regarding temperature limitations and proper installation techniques. Cold weather may affect the curing and adhesion process, so additional precautions and proper heating or insulation methods may be necessary during the application.

- Q: Can a waterproofing membrane be used to repair existing water leaks or damage?

- Repairing existing water leaks or damage can be achieved by using a waterproofing membrane. These membranes are specifically designed to form a barrier that stops water from penetrating surfaces like roofs, walls, or foundations. When applied to areas where water leaks or damage have occurred, the waterproofing membrane effectively seals off the affected region, preventing further water intrusion. However, it is crucial to understand that the success of the repair relies on the extent of the damage and the quality of the chosen waterproofing membrane. It is highly recommended to seek professional advice to assess the situation and determine the most appropriate course of action for fixing existing water leaks or damage.

Send your message to us

EPDM Waterproof Membrane for Roofing Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords