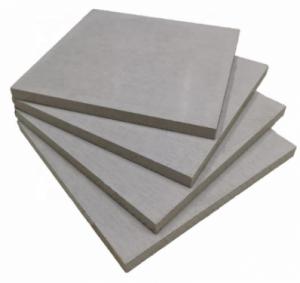

Decorative material top quality fiber cement board price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brand Name:CMAX

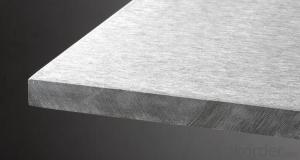

Density:More than 1.2g/cm3

Application:Ceiling ,Wall panel, Floor, partition

Specification:2440*1220mm(Length*Width)

Thickness:6/7/8/9/10/12/18/25 mm

Advantage:Easy-installing, Eco friendly

Incombustibility:GB8624-1997 Grade A1

Bending Strength:12Mpa

Type:Fiber Cement Boards

Supply Ability:10000 Piece/Pieces per Day

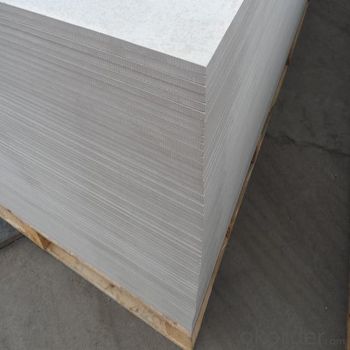

Packaging & Delivery

Packaging Details

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Port:Guangzhou or Foshan Port

Specification

1. Small board: 595*595mm /600*600mm /603*603mm /595*1195mm /600*1200mm

2. Big board: 1220*2440mm /1220*3050mm

3. Thickness: 4.5, 5, 6, 8, 10, 12, 15, 18, 20, 25mm (4.5-30mm)

Remark: Other specification is available.

Application

application: Partition wall and ceiling

Fireproof structure: Fire Rating Partition, Ceiling, wall, door,

Exterior Cladding and façade structure

Sound Insulation structure

Usage in wet areas

Other purpose: applied to furniture, interlayer floor, interior substrate

Technical Data

Item | Index | Unit | ||

Density | ≤1.20 | g/cm3 | ||

Water contain | ≤10 | % | ||

Water absorption | ≤39 | % | ||

Incombustibility | Grade A1 incombustible | |||

Bending strength | Oven dry | cross | ≥12 | M pa |

Parallel | ≥10 | M pa | ||

Fiber Cement Board With Factory Low Price

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

Board Edge:

Packaging Details:

Fumigation wooden pallets+PE cover + corner protector

- Q: What is the weight of the generally insulated panels? As much as possible to list some, thank you prawn

- In addition, this product can not be used for external wall insulation panels, deformation may not be able to hang down, down, dangerous. High-density cement fiberboard water absorption is too large, heavy weight.

- Q: Cement pressure plate to do the bathroom partition, strength and humidity can meet the requirements?

- Not recommended with cement pressure plate, there are hidden dangers. The most solid brick

- Q: I'm removing a tile floor and planning to install a hardwood floor instead. I found cement backer board under the tile. Do I need to remove the cement backer board? Or can I install the hardwood on top of that?

- if it was my house i would remove cement board and replace with wood to accept nails, if it is a floating floor you can keep it, just put tar paper doon before floating floor

- Q: ok so im trying to attach the cooling fan to my cpu on my motherboard and i cant find any glue but i did find some patch cement in a road hazard kit, i was wondering if this would work or would my computer fry?

- You need thermal paste. You can get a very small tube, enough for 1-3 applications (?) at COMPUSA (or other such place) for under $5. I work on m-boards/processors all the time and know that some kind of adhesive would probably ruin your computer. I've had many heat sinks/fans that would not separate from the processor, and sometimes lift it out of the socket without loosening the arm that tightens it. The kind of damage cant be (easily/cheaply) repaired. Get thermal paste, apply very thin amount to proc, covering the entire (proc) heat sink. Same to heat sink/fan.

- Q: i'm tiling my shower and i know i have to put up cement backboard, but do i need a vapor barrier behind it?do i cut the backerboard so the bottom of it touches the top of the tub or leave a little space between them? do i need to tape in between the boards? any help would be appreciated.

- u can put up a tar paper vapor barrier behind of the cement board if u want...anything is helpful so water does not get to the wood framing, but not really needed ....the cement board should not touch the top of the tub ( stay above the tubs lip) u do not want any wicking action....the finish tile should be an 1/8 of an inch or so off the top of the tub.....caulk between tub and tile. before u tile the corners and joints of the cement board should be meshed taped and covered with thinset. if u hage the board over the lip of the tub the your tile will not line up or you'll have a thick grout line towards the bottom corners because going over the lip will cause the bottom to flar out about an 1/8 of an inch or more.let the tile overlap the lip

- Q: how do those karate guys break cement and wood pieces by jsut like one hit, why doesnt it hurtthem or break there hands and feet?dont gimme a BS answer,im lookin for an actual reasonable explanation

- wood is easy to break against the grain. Cement requires you to spend lots of time conditioning you knuckles so you don't break them but it is possible for anyone with spare time to condition to break cement and bricks(some people start with ceiling tile). How ever there are masters in Japan that can punch a tree full strength with out breaking knuckles and master in Korea that can break Marble and i believe there is one that punched a ox and it died

- Q: Can fiber cement board be used as an external wall?

- can The composition of the cement board is mainly used in the cement, after high temperature and high pressure made of fine are generally used for external walls, in some of the warehouse to build some of the external walls are mostly used fiber cement board, and now many people do not know Fiber cement board and fiber-free difference, there is a pressure after the cement board, the latter price is more expensive than the average price, because the production of cement board in the use of high-pressure machine to pressurize Will lose a few mm thickness, the thickness of the loss is to be calculated into the pressure after the change, the density of his seismic performance and improve the performance of the anti-fold is much greater, and in the cold weather outdoors Construction can also greatly reduce the loss of products, especially in the north of the weather, for the external walls of the cement board must be pressurized, or in the construction time will consume a lot.

- Q: Gypsum board, cement board, glass magnesium board to do the kind of good ceiling

- Conventional ceiling or gypsum board is the best, easy to cut easy to shape.

- Q: How much is the cement board?

- 65 yuan a, one is 2.4 * 1.2 specifications, 22.5 yuan a square meter. The advantage is not afraid of water (compared with gypsum board), the disadvantage is fragile

- Q: What is the difference between VIVA wood chips and FOREX plum cement board?

- Weight F6 = V8 that is the United States rock plate cement density is higher than the wood board, so FOREX US rock plate than the wood board weight some FOREX6 mm is almost equal to VIVA wood cement board 8 mm weight, probably Is 31 kg (1220 * 2440MM)

Send your message to us

Decorative material top quality fiber cement board price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords