corrugated colored steel sheets 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Type: | |||

| Technique: | Surface Treatment: | Application: | |||

| Special Use: | Width: | Length: | |||

| color: |

Packaging & Delivery

| Packaging Detail: | corrugated color steel sheet /stainless color steel sheet seaworthy package with wooden pallet |

| Delivery Detail: | 20 days after receiving deposit |

Specifications

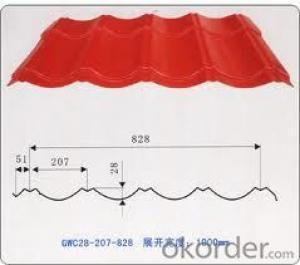

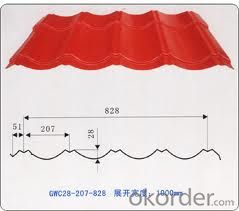

corrugated color steel sheet /stainless color steel sheet

1.Prime Quality,Low Price, Efficient Delivery.

2.Free sample.

corrugated color steel sheet /stainless color steel sheet

1. Base material: hot dipped galvanized steel

2. Width: available from 914MM to 1250MM

3. Width Tolerance: within 0.02MM

4. Thickness: available from 0.20MM to 0.80MM

5. Thickness Tolerance: within 0.15MM

6. Performance: Matte or GLossy

7. Color: according to RAL standard

8. Lacquer Coating thickness: according to customer needs

9. Supply capacity: 7000 Metric Ton per month

Our products has good performance on combining force and anti-erosion. We offer fine quality products and best price for our international customers. PPGI is light, beautiful and has good corrosion resistant performance, can be directly processed also, ppgi provides the construction, shipbuilding, vehicle manufacturing, furniture industry, and electrical industry a new material, while ppgi has good effects on the areas of replacing wood with steel, efficient construction, energy saving, prevent pollution etc.

Advantages of Our Prepainted Galvanized Steel Coil:

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Prepainted Galvanized Steel Coil:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Coating Chief Feature

| Project | Pencil hardness | Reverse impact | T bending | Cupping test | MEK cleaning |

| Front/back | ≥ H/2H | ≥ 9J/6J | ≤ 3T/5T | ≥ 6mm/4mm | ≥ 100time/50time |

Structure of GI/PPGI

| Item | Thickness | Type | Feature |

| Laminated film | 50μm | Polyethylene | Protecting from scratchs and contamination (option) |

| Top coat | 20μm | Polyester Fluorine | Chemical resistance and formability |

Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

| Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

| Substrate | 0.2mm-1.2mm | GI.GL,AL | GI.GL,AL |

| Back coat |

5±2μm |

Epoxy | Corrosion resistance and adhesion to the substrate |

- Q: What are the different quality standards for steel sheets?

- There are several different quality standards for steel sheets, including ASTM (American Society for Testing and Materials), AISI (American Iron and Steel Institute), JIS (Japanese Industrial Standards), and EN (European Norms). These standards outline specific requirements for various aspects of steel sheets, such as chemical composition, mechanical properties, dimensional tolerances, and surface finish. Compliance with these standards ensures that steel sheets meet certain quality and performance criteria and can be used for specific applications in various industries.

- Q: What are the different methods of cutting steel sheets?

- There are several different methods of cutting steel sheets, including traditional methods such as shearing, sawing, and plasma cutting, as well as more modern techniques such as laser cutting and waterjet cutting. Each method has its own advantages and limitations, and the choice of method depends on factors such as the thickness and type of steel, desired precision, and production volume.

- Q: Can steel sheets be used for insulation cladding?

- Typically, insulation cladding does not involve the use of steel sheets. Instead, materials like foam boards, mineral wool, or fiberglass are commonly chosen for their thermal insulation properties. These materials are effective in minimizing heat transfer and enhancing energy efficiency. Conversely, steel sheets are more frequently utilized for structural purposes or as a protective layer owing to their robustness and durability. Though steel sheets can offer some protection, they lack the requisite insulation properties required to effectively prevent the transfer of heat or cold. Consequently, it is advisable to employ suitable insulation materials specifically designed for cladding purposes.

- Q: What is the average lead time for manufacturing steel sheets?

- The average lead time for manufacturing steel sheets can vary depending on various factors such as the size and complexity of the order, the manufacturing process employed, and the current demand and capacity of the steel sheet production facility. However, in general, the average lead time for manufacturing steel sheets can range from a few weeks to a few months. If the order is relatively small and standard in size, the lead time may be shorter, typically ranging from 2 to 6 weeks. This time frame allows for the procurement of raw materials, processing, and quality control procedures to ensure the final product meets the required specifications. On the other hand, if the order is larger or involves more complex specifications, the lead time may be longer. This is because additional time may be required for customizing the steel sheets according to specific dimensions, finishes, or treatments. In such cases, the lead time can extend to several months. It is important to note that lead times can also be influenced by external factors such as supply chain disruptions, unforeseen delays in raw material procurement, or fluctuations in demand. Therefore, it is always advisable to consult with the steel sheet manufacturer or supplier for an accurate estimate of the lead time based on the specific requirements of the order.

- Q: What is the average weight of a steel sheet per square foot?

- The weight of a steel sheet per square foot can change based on its thickness and the type of steel employed. Nevertheless, a typical weight range for a steel sheet per square foot falls between 40 and 70 pounds. It is crucial to understand that this is a rough approximation, and the actual weight may deviate due to specific factors like alloy composition and the manufacturing process.

- Q: How do steel sheets perform in terms of electrical conductivity?

- Steel sheets are poor conductors of electricity compared to materials like copper or aluminum.

- Q: What are the different methods of protecting steel sheets from scratches?

- There are several methods of protecting steel sheets from scratches. One common method is applying a protective coating or paint on the surface of the steel sheet. This coating acts as a barrier and prevents scratches from occurring. Another method is using a temporary protective film or tape on the steel sheet. This film or tape can be easily applied and removed, providing a temporary safeguard against scratches. Additionally, using padded or protective packaging during transportation or storage can help prevent scratches. Implementing proper handling and storage procedures, such as using non-abrasive materials and avoiding stacking or sliding steel sheets, can also minimize the risk of scratches.

- Q: Can the steel sheets be used for metal stamping?

- Yes, steel sheets can be used for metal stamping. Steel is a commonly used material for metal stamping processes due to its durability and strength. The steel sheets are typically cut into specific shapes and sizes, and then undergo a stamping process where a die and punch set are used to form the desired shape on the steel sheet. This process can be used to create various products such as automotive parts, household appliances, and industrial components.

- Q: Can steel sheets be used in the medical industry?

- Yes, steel sheets can be used in the medical industry. They are often used in the manufacturing of medical equipment, surgical instruments, and medical furniture due to their durability, corrosion resistance, and ease of sterilization.

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- Plain carbon steel sheet and stainless steel sheet are both types of steel sheets, but they have several distinct differences. The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made up of iron and carbon, with small amounts of other elements such as manganese and silicon. It is known for its strength and durability, making it suitable for a wide range of applications. However, plain carbon steel is prone to rust and corrosion when exposed to moisture or certain chemicals. On the other hand, stainless steel sheet is made up of iron, carbon, and a minimum of 10.5% chromium. This addition of chromium forms a protective layer on the surface of the steel, known as a passive film, which prevents corrosion and rusting. Stainless steel is highly resistant to stains, heat, and corrosion, making it ideal for applications where hygiene and durability are crucial, such as in the food and medical industries. Another significant difference between the two types of steel sheets is their appearance. Plain carbon steel sheet has a dull grey finish, while stainless steel sheet has a shiny, reflective surface. This aesthetic difference is often a consideration in industries where the visual appeal of the material is important, such as architectural or interior design applications. Furthermore, stainless steel sheet has a higher price point compared to plain carbon steel sheet. This is due to the additional alloying elements, such as chromium and nickel, which are added to enhance its corrosion resistance and other properties. The higher cost of stainless steel is often justified by its superior performance and longevity in corrosive environments. In summary, the key differences between plain carbon steel sheet and stainless steel sheet are their composition, properties, appearance, and price. Plain carbon steel is strong but prone to rust, while stainless steel is corrosion-resistant and has a shiny finish. The choice between the two depends on the specific requirements of the application, including the need for corrosion resistance, aesthetics, and budget.

Send your message to us

corrugated colored steel sheets 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords