Color Coated Steel Sheet (ASTM A755) for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:Ral 3012

Standard:AISI

Steel Grade:ASTM A755

Surface Treatment:Coated

Technique:Cold rolled, Hot dipped, Pre-painted

Export Markets:Global

Additional Info.

Packing:Standard Sea Worthy Package

Standard:ASTM A755

Origin:China

HS Code:72107000

Production Capacity: 18, 000~25, 000 Tons Per Month.

Product Description

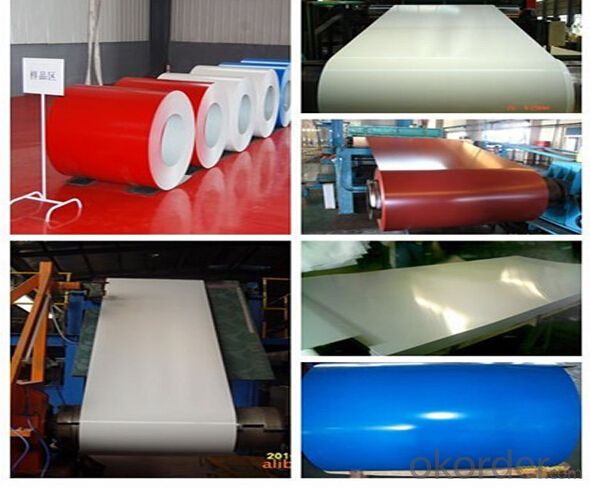

NAME: Prepainted Steel Coil\Colour Coated Coil\Coil coated steel\PPGI

SIZE:

Thickness: 0.18-1.50mm

Width: 10mm-1500mm(STD914mm,1000mm, 1200mm, 1219mm, 1250mm, 1500mm)

Thickness tolerance: +/-0.05 mm

Width tolerance: -2.0/5.0mm

ZINC, PAINT & COLOR:

Zinc coating: 60-275G/M2

Paint thickness: Top 15-25um + Back 5-10um

Paint: polyester, silicone polyester, acrylic, fluoropolymer, plastisol, or polyurethane

Color: As the RAL color standard or customer's sample

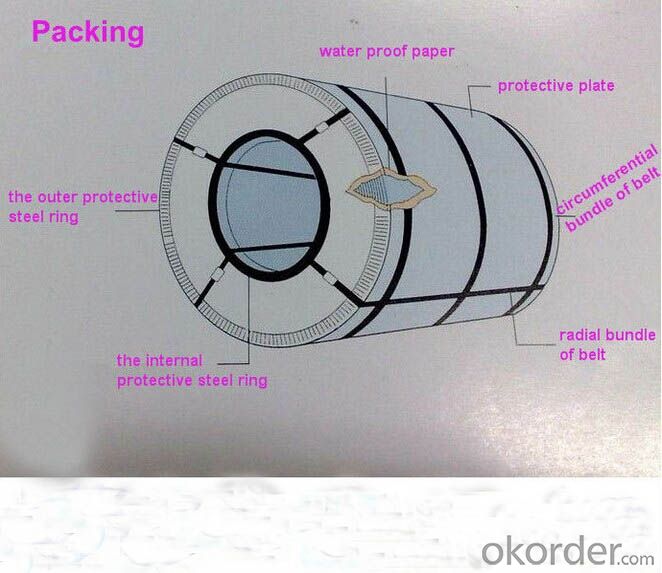

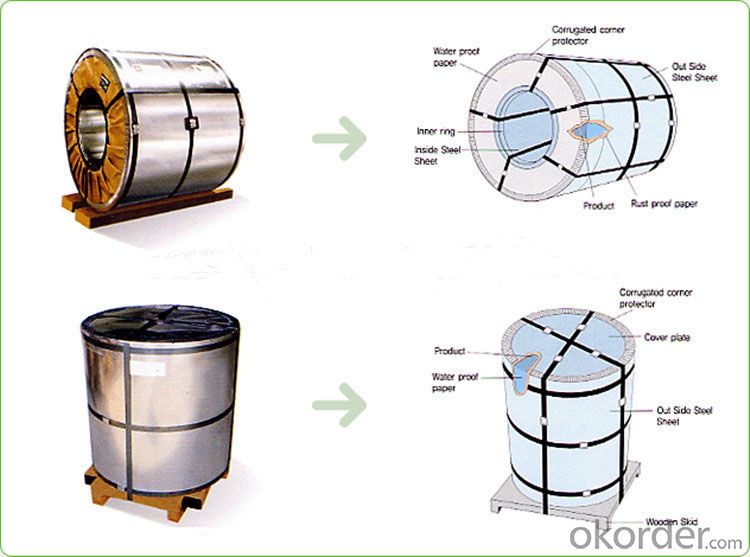

PACKING:

Coil weight: 3-10tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: SGCC, CGCC, DC51D+Z, Q195,etc

Quality: CQ DQ

Lifespan: 10-15 years

APPLICATION:

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door\Door of garage\Roller shutter door\Booth\Persian blinds\Cabana\Refrigerated wagon and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\Sliding door\Folding screen\Ceiling\ Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: How are steel coils used in the manufacturing of tools and equipment?

- Steel coils are used in the manufacturing of tools and equipment as they provide a versatile and durable material for construction. These coils are typically shaped, cut, and molded into various components such as blades, shafts, and handles, which are then assembled to create the final product. The strength and resilience of steel make it an ideal choice for tools and equipment, ensuring longevity and optimal performance in various industries.

- Q: What are the different types of steel coil finishes used in architectural applications?

- There are several types of steel coil finishes commonly used in architectural applications. These include mill finish, galvanized finish, painted finish, and stainless steel finish. Mill finish refers to the natural appearance of steel after it has been processed, which typically has a smooth, matte surface. Galvanized finish involves coating the steel with a layer of zinc to provide corrosion resistance. Painted finish involves applying a coat of paint to the steel surface, offering both protection and aesthetic appeal. Lastly, stainless steel finish involves using a steel alloy with a high percentage of chromium, resulting in a shiny and corrosion-resistant surface.

- Q: PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q: How do steel coils perform in high-pressure applications?

- Steel coils perform well in high-pressure applications due to their inherent strength and durability. The high tensile strength of steel allows it to withstand the intense pressure without deformation or failure. Additionally, steel coils can be manufactured to precise specifications, ensuring they can handle the specific pressure requirements of the application. Overall, steel coils are a reliable and efficient choice for high-pressure applications.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being uncoiled and then fed through a series of machines where they are drawn, stretched, and twisted to the desired diameter and shape. This process helps to strengthen the wires and make them more flexible for various applications such as electrical wiring, construction, and manufacturing.

- Q: How are steel coils used in the manufacturing of food processing equipment?

- Steel coils are used in the manufacturing of food processing equipment as they provide a strong and durable material for constructing various components such as conveyor belts, mixing blades, and cutting tools. The coils are typically shaped, cut, and molded to create specific parts that can withstand high temperatures, heavy loads, and corrosive conditions commonly encountered in food processing.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- This Site Might Help You. RE: Why can aluminum and steel casings not be used for reloading? I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- No, a steel string guitar is built and braced for the greater tension of steel strings, which means it's too heavily built to respond properly to nylon strings. It would sound awful. Besides, the slots in the nut are too narrow on a steel-string, the action is too low, and the bridge is made for ball end strings (most high quality nylon strings are plain end). And you would have to turn the narrow string posts on steel-string tuners forever to get anywhere with stretchy nylon strings.

- Q: What is the current value of steel? Is it expected to increase in value?

- The steel in steel cents is the same as the steel in soup cans you throw out all the time. There is no sense in holding steel cents for their value as scrap. There are way too many steel cents around for them to ever have much numismatic value.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- The reason the steel wool catches fire is because the strands of steel are so fine and they have a high resistance. The thin strands get to red-hot very quickly, compared to larger gauge copper wire which has lower resistance and can dissipate the heat over its larger mass. When you connect the battery to the wire first, then touch the steel wool, you are making solid contact with the steel wool and your hand makes sure that the wire stays in contact. The current continues to flow and the wool heats up. When you connect the wire to the steel wool first, as soon as you connect the battery the current melts that tiny bit of steel wool touching the wire and electrical contact is lost. The current stops flowing. No fire. If you want to connect the wire first and not have to hold it, you have to make sure that the current keeps flowing, perhaps by using a braided copper wire and spreading out the individual strands to make multiple contacts. Either that, or remove the insulation from a longer section of the wire and make sure that the entire un-insulated part of the wire is in contact with the steel wool. Maybe even weigh it down. Remember that any strands of steel wool touching that wire will melt as soon as the current starts, so you have to make sure that the wire will maintain contact somehow, the same way that your hand pushes the wire against it.

Send your message to us

Color Coated Steel Sheet (ASTM A755) for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords