CMAX Non Woven Geotextile Manufactory 300g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

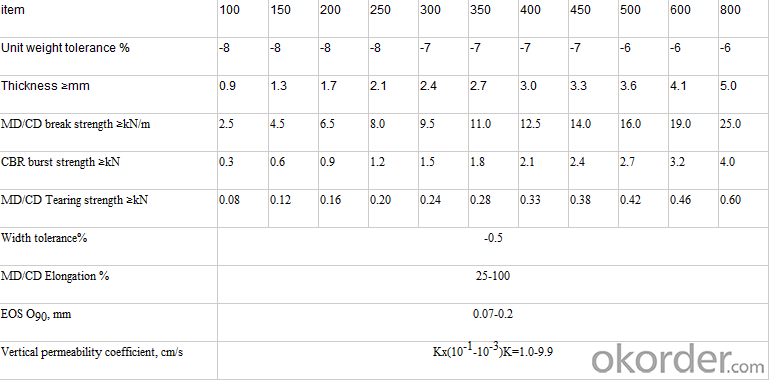

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q:300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q:Can geotextiles be used in road construction?

- Yes, geotextiles can be used in road construction. They are often used as a geosynthetic material to reinforce the soil and provide stability to the road base. Geotextiles can also act as a separation layer, preventing the mixing of different layers of soil or aggregate materials. Additionally, they can help in drainage by allowing water to pass through while preventing soil erosion. Overall, geotextiles are beneficial in enhancing the performance and longevity of roads.

- Q:What are the advantages of using geotextiles in hydraulic applications?

- Geotextiles offer several advantages in hydraulic applications. Firstly, they provide excellent filtration properties, allowing water to pass through while retaining soil particles. This helps in preventing soil erosion and maintaining the stability of hydraulic structures. Secondly, geotextiles act as a barrier against soil migration, reducing the likelihood of clogging or blockage in drainage systems. Additionally, they enhance the overall durability and longevity of hydraulic structures by distributing loads and reducing stress on underlying soils. Lastly, geotextiles are lightweight and easy to install, making them a cost-effective solution for various hydraulic projects.

- Q:Geotextile between the use of lap, lap width is not less than?

- Lap width is generally 0.2M or more.

- Q:How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and promoting vegetation growth. These synthetic fabrics act as a barrier that prevents soil erosion caused by waves, tides, and currents. Geotextiles also help to distribute hydraulic pressure, reducing the impact of water on shorelines. Additionally, they facilitate the growth of vegetation by retaining moisture and providing a stable base for plant roots, further reinforcing the shoreline and enhancing its overall performance.

- Q:Where to sell waterproof geotextile

- Building materials market should have hope to help you

- Q:What are the key considerations for geotextile installation in corrosive environments?

- Some key considerations for geotextile installation in corrosive environments include selecting a geotextile material that is resistant to corrosion, ensuring proper installation techniques to prevent exposure of the geotextile to corrosive substances, and monitoring the condition of the geotextile regularly to detect any signs of corrosion or degradation. Additionally, it is important to consider the potential impact of the corrosive environment on the overall performance and lifespan of the geotextile.

- Q:What are the standards and specifications for geotextiles?

- Geotextiles are specifically engineered fabrics used in civil engineering projects to enhance soil stability, filtration, drainage, and separation. The standards and specifications for geotextiles are established by various organizations, including the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards outline the testing methods and performance requirements for geotextiles in terms of their physical properties, strength, durability, and resistance to environmental factors. These standards ensure that geotextiles meet the necessary quality and performance criteria for their intended applications, promoting consistency and reliability in the construction industry.

- Q:What are the advantages of using geotextiles in shoreline stabilization projects?

- Geotextiles offer several advantages in shoreline stabilization projects. Firstly, they provide effective erosion control by stabilizing soil and preventing it from being washed away by waves or currents. This helps maintain the integrity of the shoreline and prevents further erosion. Secondly, geotextiles act as a filter barrier, allowing water to pass through while trapping fine particles and preventing sedimentation. This helps maintain water quality and prevent the buildup of silt or pollutants. Additionally, geotextiles are highly durable and resistant to degradation, making them a cost-effective and long-lasting solution for shoreline stabilization.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Non Woven Geotextile Manufactory 300g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords