4 Oz Needle Punched Nonwoven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Discription:

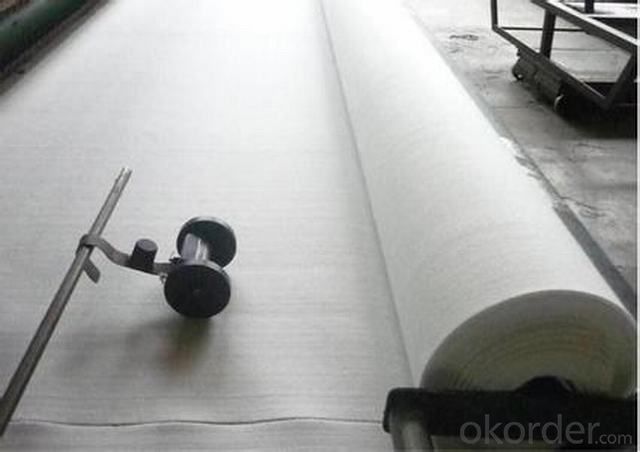

OKorder is offering high quality Needle Punched Nonwoven Geotextiles for River Construction at great prices with worldwide shipping.

Our Geotextiles are available in a wide range of types and dimensions. Our supplier is a world-class manufacturer and our products are utilized

the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets.

We provide quotations within 24 hours of receiving an inquiry and guarantee a competitive price.

Product Applications:

OKorder's Needle Punched Nonwoven Geotextile for River Construction and related products have many applications and currently

support many civil engineering applications including roads, airfields, railroads, embankments, retaining structures, reservoirs, canals, dams,

bank protection, coastal engineering and construction site silt fences or geotubes.

Product Advantages:

OKorder's Geotextiles are made from polypropylene staple fibers on cross-laying and needle punch equipment.

Our advanced production methods result in Geotextiles that are very high strength, have excellent elongation and high biological tolerances.

Main Product Features:

· Acid and alkali resistant

· Erosion aging resistant

· Excellent filtration

· Easy installation

· Low cost

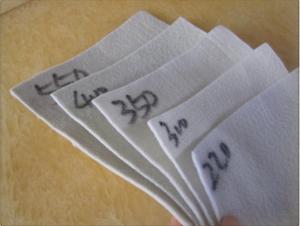

Product Specifications:

Material: PP / PET

Weight: 100g/m² – 1500g/m²

Length: 50m – 100m/roll (Per request)

Width: 1m – 8m

Certification: CE / ISO9001

Color: Black, white, grey

Manufacturing method: Nonwoven / Woven

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are the differences between Nonwoven and Woven Geotextiles?

A3: Nonwoven Geotextiles are made of directionally or randomly orientated fibers, filaments or other elements, mechanically and/or thermally and/or adhesively bonded Woven Geotextiles are produced by interlacing two or more sets of yarns, fibers, filaments, tapes or other elements.

Q4: What are the differences between needlepunched and thermally bonded Nonwoven Geotextiles?

A4: Needlepunched Geotextiles are produced by entangling continuous or short fibers by needles. This so called mechanical bonding can be improved by additional thermal bonding thermally bonded Geotextiles are produced by bonding randomly or directionally orientated fibers using thermal treatment.

Q5: Which role does the polymer play in the properties of the Geotextile?

A5: Different polymers are used for the production of Geotextiles. The selection of a polymer depends mainly on properties like melting point, density, melt flow index and more that influence the different production processes. Usually the polymer is modified using additives and stabilizers in order to improve the characteristics. It is the final manufactured product that is of primary interest to the end user.

Q6: What is the difference between Geotextiles and Geosynthetics?

A6: Geosynthetics is the generic term for products where at least one component is made from a synthetic or natural polymer used in contact with soil and/or other materials in geotechnical and civil engineering applications. Geotextiles are planar, permeable, polymeric textile products and are one type of geosynthetics.

- Q: What is the coefficient of friction for nonwoven geotextiles? What is the coefficient of friction between rock and soil?

- My company specializes in the production of geotechnical materials, treat people with sincerity to ensure your satisfaction.

- Q: What are the advantages of using geotextiles in waste containment systems?

- Geotextiles offer several advantages in waste containment systems. Firstly, they act as a barrier, preventing the migration of contaminants from the waste site into the surrounding environment. Secondly, they provide stability and reinforcement to the waste containment structure, enhancing its strength and durability. Additionally, geotextiles facilitate proper drainage and filtration, allowing for the efficient removal of excess water and leachate. They also minimize soil erosion, which is crucial for long-term stability. Overall, geotextiles improve the performance and longevity of waste containment systems while minimizing environmental risks.

- Q: How do geotextiles contribute to sustainable construction practices?

- Geotextiles contribute to sustainable construction practices by providing a range of beneficial functions. They can stabilize soil, prevent soil erosion, and enhance drainage systems, which reduces the need for excessive excavation and reduces the amount of construction materials required. Geotextiles also promote environmental protection by filtering out pollutants and preventing their migration into surrounding areas. Additionally, they prolong the lifespan of infrastructure, reducing the need for frequent repairs and replacements, thereby minimizing the consumption of resources and energy. Overall, geotextiles play a vital role in sustainable construction practices by promoting efficiency, cost-effectiveness, and environmental conservation.

- Q: Geotextile what is the law?

- Geotextiles, engineering cloth, impermeable cloth, non-woven fabrics, polyester cloth, health cloth, permeable cloth, etc., which are based on the use of different materials or different materials. But in fact are geotextiles. Geotextile types are many: woven geotextile, staple acupuncture geotextile, filament geotextile, impervious geotextile, non-woven geotextile, composite geotextile, warp-resistant geotextile

- Q: What is the high strength to strengthen the composite geotextile

- Bujia Weaving Bugatite Rope

- Q: Hope expert expert to give the answer

- 1, side ditch, drains, blind ditch, cut ditch are road drainage facilities. 2, the drainage system is divided into the form of surface water and row of groundwater. Row of surface water: side ditch, drains, cut ditch; row of groundwater: blind ditch. 3, according to the road plane position is divided into: side ditch in the road side; drains can also be in the road side in the central zone; trench in the cutting section above; blind ditch in the roadbed width range. 4, according to the direction of the road is divided into: the direction of the ditch along the way; drains can also be the direction of the road can also cross the direction; cut the ditch along the way; blind ditch can be any direction. 5, according to the drainage function and cross-sectional size is divided into: drainage section of the largest; blind ditch second; side ditch, cut the smallest ditch. 6, according to the construction materials can be divided into: ditch can be pulp, dry piling, ramming, etc .; drains for the pulp or dry puzzle; blind ditch for the dry, pulp, gravel, concrete, ) And other combinations; cut ditch for the dry, pulp, ramming and so on. 7, according to the embankment type is divided into: fill, fill in the dug with a ditch, ditch, blind ditch; digging side, half filled half digging section ditch, drains, blind ditch, The ditch appears only in the digging section.

- Q: Welding of impervious geotextile

- 1. Seam processing is the key to the construction process, the general use of heat welding method, PE film surface heat treatment, so that the surface melting, and then through the pressure, so that one fusion. 2. For the laying of a good geomembrane, edge seams require no oil, water, dust and so on. 3. Before welding to adjust the seam at the two sides of the PE single film, so that a certain width of the lap, lap width is generally 6 ~ 8 cm and smooth, no wrinkles. 4. Use special welding machine for welding. Welding construction effect map:

- Q: Can geotextiles be used in coastal revetment works?

- Yes, geotextiles can be used in coastal revetment works. Geotextiles are commonly used as a component in coastal revetment systems to provide erosion control and stabilization. They can help to reinforce the soil, prevent erosion, and enhance the stability of the revetment structure.

- Q: The secondary lining of the tunnel to install the vertical ring to the blind tube hang the geotextile waterproof board generally used for how long

- See the progress of the project

- Q: What are the limitations of geotextiles?

- Geotextiles have some limitations that may hinder their effectiveness in certain applications. Firstly, they are not designed to provide structural support and cannot bear heavy loads. Secondly, geotextiles are susceptible to damage from ultraviolet radiation and may degrade over time when exposed to sunlight. Additionally, they may not be suitable for use in high-flow or high-velocity water conditions as they may become clogged or displaced. Lastly, geotextiles may have limited resistance to certain chemicals and may not be compatible with certain soil types or environmental conditions.

Send your message to us

4 Oz Needle Punched Nonwoven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords