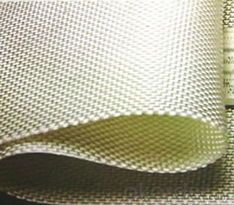

Double Punched Non Woven Geotextile - Yong Run Filament Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product features:

Woven geotextile with high strength, low elongation polypropylene, polyester and other synthetic fiber filament do raw material, the special manufacture process, high wear resistance, bursting resistance, tensile strength.

Mixer tensile and tearing resistance, bursting resistance, resistance to puncture, such as high mechanical strength, is equally grams weighs more than doubling of staple fiber geotextile;

Good extension performance, stress dispersion and transmission is fast, make the uniformly distributed load;

In construction of friction coefficient is big, not easy to slip;

Corrosion resistance, excellent chemical resistance;

Resistance to ageing, embedded laid, the service life of 50 years;

Mixer heat, cold resistant performance is good.

Scope of application:

Apply to jianghai river, coastal sea water catchments, harbor of slope protection, protection of beach and soft soil foundation treatment.

Product specifications:

Wide: 2-6.2 m;

G: 180 g - 670 - g / ㎡.

- Q: Can geotextiles be used in geosynthetic reinforced walls?

- Yes, geotextiles can be used in geosynthetic reinforced walls. Geotextiles are commonly used as a separation and filtration layer in geosynthetic reinforced walls to prevent soil erosion, improve drainage, and provide stability to the structure.

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include exposure to environmental conditions such as ultraviolet (UV) radiation, temperature variations, moisture, and chemical exposure. The quality of the geotextile material and its resistance to degradation, abrasion, and puncture also play a crucial role in determining its durability. Proper installation, maintenance, and adherence to design specifications are additional factors that can impact the longevity of geotextiles.

- Q: How do geotextiles help in slope stabilization?

- Geotextiles help in slope stabilization by providing reinforcement and erosion control. They are placed within the slope to increase its strength, prevent soil movement, and reduce erosion. The geotextiles act as a barrier to retain soil particles while still allowing water to pass through, thus minimizing water-induced damage and promoting vegetation growth. Overall, geotextiles play a crucial role in improving slope stability and reducing the risk of landslides.

- Q: What are the factors to consider when designing geotextile tubes for dewatering?

- When designing geotextile tubes for dewatering, there are several factors to consider. Firstly, the type and characteristics of the sediment or sludge being dewatered should be evaluated, including its composition, particle size distribution, and consolidation properties. This information will help determine the appropriate geotextile fabric and pore size required to effectively retain the solids while allowing water to drain. Secondly, the hydraulic loading conditions need to be considered. The flow rate, pressure, and duration of the dewatering process will influence the required strength and permeability of the geotextile tubes. Adequate strength is crucial to withstand the hydraulic forces and prevent structural failure. Additionally, the site conditions and environmental factors should be taken into account. The stability of the ground where the geotextile tubes will be placed, as well as any potential erosion or slope stability issues, should be thoroughly analyzed. The project location, climate, and potential impact on surrounding ecosystems should also be considered to ensure the chosen design is sustainable and minimizes any adverse effects. Lastly, the cost-effectiveness and practicality of the design should be evaluated. Factors such as the availability and cost of materials, installation methods, and maintenance requirements should be considered to optimize the overall dewatering process. Overall, designing geotextile tubes for dewatering requires a comprehensive assessment of sediment characteristics, hydraulic loading conditions, site conditions, and cost-effectiveness to ensure a successful and efficient dewatering solution.

- Q: What is PAG in PAG composite geotextile

- Should be a high-strength glass fiber or grille and non-woven woven or bonded together geotextile, PAG is estimated that the product is a product code, one may be nominal vertical and horizontal strong, similar geogrid Such as PAG50-160, the other may be used cloth and grille specifications, such as 50kn grille and 160 grams of nonwovens

- Q: How do geotextiles affect soil moisture retention?

- Geotextiles can significantly impact soil moisture retention by acting as a barrier between the soil and the external environment. They help in reducing excessive evaporation from the soil surface, thus minimizing water loss. Additionally, geotextiles prevent the erosion of soil particles, maintaining soil structure and facilitating better water infiltration. This ultimately improves soil moisture retention by creating a more favorable and stable environment for plants to grow.

- Q: Can geotextile be used as an insulation film?

- Yes, the company produces the country, the best quality geotextile materials, for example, long, short wire geotextile. Geotextile composite film. All kinds of grille, waterproof board and so on. Short wire geotextile prices, geotextile composite film specifications and other quality and cheap! The The Welcome to call to discuss, 0534-. Xujing Li.

- Q: Are geotextiles resistant to creep deformation?

- Yes, geotextiles are generally resistant to creep deformation. They are designed to have low deformation properties under constant or sustained loads, making them effective in preventing or minimizing creep.

- Q: What are the limitations of using geotextiles in high-water flow conditions?

- One limitation of using geotextiles in high-water flow conditions is their potential to clog or become blocked with sediment or other debris. This can reduce their effectiveness in filtering water or preventing erosion. Additionally, geotextiles may not be able to withstand the extreme forces exerted by fast-moving water, leading to their failure or displacement. Therefore, it is crucial to carefully consider the flow conditions and choose appropriate geotextiles with sufficient strength and porosity for the specific application.

Send your message to us

Double Punched Non Woven Geotextile - Yong Run Filament Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords