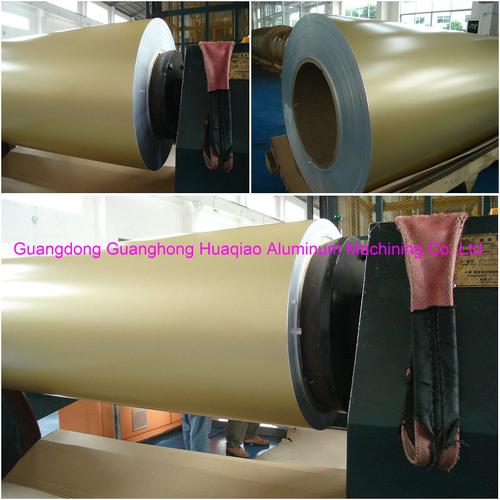

Champagne gold color PVDF coated aluminum coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of PVDF AluminumCoil:

1. Adopting precision rolling coating technology,our PE coated coil can ensure excellent adhesive without coating omission.

2. For the PVDF coated aluminum sheet we produced,there are various colors for your choice.

3. Using infrared heating technology to protectenvironment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

Raw Material of the PVDF Coated Aluminum Coil:

1. Aluminum Coil: high strength aluminum with alloyof AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005 according tocustomer)

2. Surface Paint: PE, PVDF and special paints.

Performance and usage

PVDF coated aluminum coils are specially processedthrough the technics of roller coating and baking with precise paints fromBECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color of Card

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Our color Coated Aluminum Coil Characteristics:

-High temperature resistant

-Weathering resistant

-Scrubbing resistant

-Sound insulation

-Acid or alkali proof

-Fireproof

-Light weight material is easy to construct and install

-Bright colors

-Easy molding process,not rusting etc.

PVDF coated aluminum coils Specification:

* substrates: Aluminium (AA 1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), PET, etc.

* Thickness: Alu. 0.08~1.00mm

* Width: Maximum 1590mm

* Colors and finishes: Solid, metallic, stone/wood look, anti-graffiti, anti-static, anti-abrasion, spectra, wrinkle, etc.

* coating systems: Ployester, PVDF, FEVE, Epoxy, Polyamide, Polyurethan, etc.

* Further processing: Strips, cut, emboss, and packing.

IDEABOND color coated aluminium foil combines all advantages of modern coil-coating technology in our full-automatic production line. Our modern production is 4 coated in one with digital precision control, we can created pattern like Wood, stone, graphic as you want. The aluminium substrate gets degreased, chemically pre-treated and coated in a single production step which resulting in a high-quality uniform coatingreproducible at any time and a material which has been developed for easy processing for a variety of application.

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications. Aluminum is known for its excellent thermal conductivity, which means it is highly effective in transferring heat. Aluminum coils are commonly used in various heat transfer applications such as air conditioning systems, refrigeration units, and heat exchangers. The lightweight and corrosion-resistant properties of aluminum also make it a popular choice for these applications. Additionally, aluminum coils can be easily shaped and formed, allowing for efficient heat transfer in complex systems.

- Q: Are aluminum coils suitable for curtain wall systems?

- Yes, aluminum coils are suitable for curtain wall systems. Aluminum is a popular material choice for curtain walls due to its strength, lightweight nature, and corrosion resistance. Aluminum coils provide flexibility in design, ease of installation, and durability, making them an ideal choice for curtain wall systems.

- Q: This question asks for a comparison of various types of insulation materials, highlighting their unique characteristics and differences.

- <p>Different types of insulation materials vary in their properties such as thermal resistance (R-value), fire resistance, moisture resistance, and environmental impact. Fiberglass is a common, cost-effective option with good thermal resistance but can be irritating to the skin and respiratory system. Cellulose insulation is made from recycled paper and has good sound absorption but may be less fire resistant. Foam insulation like spray foam offers excellent insulation and air sealing but can be more expensive and harder to install. Mineral wool is fire-resistant and durable but may be less thermally efficient. Each type has its advantages and drawbacks, and the choice depends on factors like cost, environmental impact, and specific insulation needs.</p>

- Q: Is it possible to utilize steel wires in the creation of jewelry or decorative items?

- <p>Yes, you can use steel wires for making jewelry or decorations. Steel wires are durable and can be shaped into various forms, making them suitable for a range of designs. They are often used in wire wrapping techniques and can be combined with beads or other materials. However, it's important to consider the type of steel used; stainless steel is more resistant to rust and is commonly preferred for jewelry making. Additionally, steel wires may require special tools for cutting and bending, and proper safety measures should be taken during the crafting process.</p>

- Q: How are aluminum coils protected against UV exposure during storage?

- Aluminum coils are typically protected against UV exposure during storage through the application of a protective coating or the use of UV-resistant packaging materials. Aluminum coils are highly susceptible to UV degradation, which can result in discoloration, surface damage, and reduced performance. Therefore, manufacturers and distributors take special precautions to ensure that the coils are shielded from harmful UV rays. One common method is the application of a protective coating on the surface of the coils. This coating acts as a barrier between the aluminum material and UV radiation, preventing direct exposure. The coating is typically a specialized paint or lacquer that contains UV inhibitors, which absorb or reflect UV rays, thereby minimizing damage to the coils. This protective layer also helps to preserve the aesthetic appearance of the coils and extend their lifespan. In addition to coatings, aluminum coils can also be stored in UV-resistant packaging materials. These materials are designed to block or absorb UV radiation, effectively creating a shield around the coils. Common UV-resistant packaging materials include polyethylene films, which are specifically formulated to provide excellent UV protection. By storing the coils in such packaging, they are safeguarded against direct sunlight and other sources of UV radiation. It is worth noting that UV protection measures are particularly crucial during long-term storage or transportation, as the coils may be exposed to UV rays for extended periods. By implementing these protective measures, manufacturers and distributors ensure that the aluminum coils maintain their quality and performance, even when stored in environments with high UV exposure.

- Q: What are the different tempers of aluminum coils?

- Different levels of hardness and strength can be achieved through various heat treatments for aluminum coils, resulting in different tempers. These tempers alter the physical and mechanical properties of the coils to suit specific applications. Aluminum coils can undergo different tempering processes to modify their properties. The most common tempers for aluminum coils are as follows: 1. O Temper (Soft): This represents the annealed state of aluminum, where the metal is fully soft and easily moldable. It has low strength but excellent ductility, making it suitable for applications that require extensive shaping or bending. 2. H14 Temper (Half Hard): This offers moderate strength and hardness, while still maintaining some formability. It is used in applications that require a balance between strength and flexibility, such as roofing or cladding. 3. H18 Temper (Hard): This provides high strength and hardness, with reduced formability. It is commonly used in applications that demand structural integrity and resistance to deformation, such as automotive parts or industrial equipment. 4. H22, H24, H26 Temper (Extra Hard): These tempers are achieved through additional cold working or strain hardening processes. They offer even higher strength and hardness but sacrifice some ductility. They are often used in applications that require enhanced mechanical properties, such as aerospace components or high-stress structural parts. 5. T Temper (Tension Leveled): This involves stretching the aluminum coil beyond its elastic limit and then stabilizing it. It helps eliminate internal stresses and improve flatness, making it suitable for applications that demand precise dimensional stability, such as electronic devices or architectural panels. It's important to note that there are many other tempers available for aluminum coils, each designed to meet specific requirements. The choice of temper depends on factors such as the intended application, desired mechanical properties, and processing capabilities.

- Q: How are aluminum coils used in electrical applications?

- Due to their advantageous properties, aluminum coils find wide application in various electrical uses. Transformers, motors, and inductors are the primary domains where these coils are employed. Transformers utilize aluminum coils to facilitate the transfer of electrical energy from one circuit to another. These coils are wrapped around a magnetic core, thereby facilitating efficient energy transfer. Aluminum coils are preferred over copper coils in transformers due to their affordability, light weight, and superior conductivity. Moreover, aluminum coils exhibit higher thermal conductivity, enabling better heat dissipation. This feature is crucial for maintaining transformer efficiency and longevity. In motors, aluminum coils serve as the winding material for the stator, which is the stationary component of the motor. By passing an electrical current through the coils, a magnetic field is generated. This magnetic field interacts with the rotating magnetic field produced by the motor's rotor, resulting in motor rotation. Aluminum coils are favored in motors due to their lightweight nature, contributing to overall motor efficiency by reducing its weight. Inductors, another electrical component, employ aluminum coils. Inductors store electrical energy in the form of a magnetic field. When an electric current traverses the coil, a magnetic field is generated, which opposes changes in the current. Aluminum coils are utilized in inductors owing to their high electrical conductivity, facilitating efficient energy storage and release. In summary, aluminum coils are extensively used in electrical applications due to their cost-effectiveness, lightweight nature, excellent conductivity, and high thermal conductivity. Their application in transformers, motors, and inductors plays a pivotal role in ensuring efficient and reliable operation of electrical systems.

- Q: How are aluminum coils tested for quality?

- Aluminum coils are tested for quality through various methods including visual inspections, thickness measurements, surface roughness analysis, and mechanical testing such as tensile strength and elongation tests. Additionally, other quality control measures such as chemical composition analysis, corrosion resistance testing, and adherence to specific industry standards are also carried out to ensure the overall quality of aluminum coils.

- Q: What is the temperature range within which aluminum coil can be used?

- <p>Aluminum coil can be used within a wide temperature range, typically from -200掳C to 150掳C. At low temperatures, it retains good ductility and strength, while at higher temperatures, it maintains its form and conductivity. However, it's important to note that prolonged exposure to temperatures above 150掳C can lead to a loss of mechanical properties over time. Always refer to specific product data sheets for precise temperature limits.</p>

- Q: Are aluminum coils suitable for insulation purposes?

- Indeed, aluminum coils are well-suited for insulation purposes due to their exceptional heat and electricity conductivity. This quality makes them a perfect selection for insulation applications. Aluminum coils find utility in a wide range of uses such as HVAC systems, refrigeration units, and electrical wiring. Typically, these coils are coated with an insulating material like polyurethane foam or fiberglass to augment their insulation capabilities. The amalgamation of aluminum and insulation works wonders in impeding the transfer of heat or cold, thereby providing superb thermal insulation. Moreover, aluminum is lightweight, sturdy, and resistant to corrosion, rendering it a dependable choice for long-lasting insulation requirements.

Send your message to us

Champagne gold color PVDF coated aluminum coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords