Insulating Fire Brick - Chamotte Refractory Insulated Fire Bricks for Fireplace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulated Fire Brick

CMAX Insulated Fire Brick are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature of Insulated Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulated Fire Brick

CMAX Insulated Fire Brick can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Image of Insulated Fire Brick

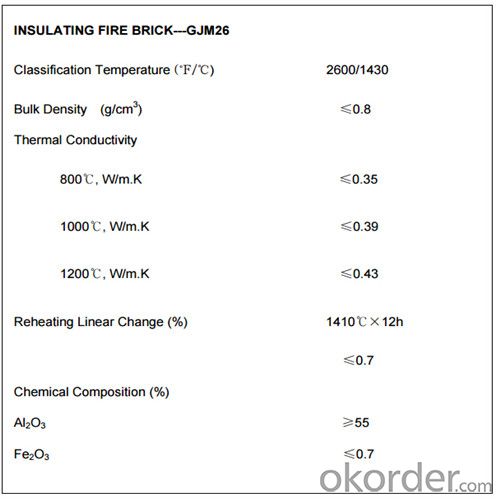

Technical Data of Insulated Firebricks

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can insulating fire bricks be used in rocket stove designs?

- Yes, insulating fire bricks can be used in rocket stove designs. Rocket stoves are known for their efficient combustion and heat transfer, and insulating fire bricks can enhance this performance. These bricks are made from lightweight materials that have high insulating properties, allowing them to retain and reflect heat efficiently. In a rocket stove, the combustion chamber is typically lined with insulating fire bricks to maximize the heat transfer to the cooking surface or space being heated. The bricks help to retain heat within the combustion chamber, ensuring that more of the energy from the burning fuel is used to heat the cooking surface rather than being lost to the environment. Additionally, insulating fire bricks can withstand high temperatures, making them ideal for rocket stove designs. They are designed to handle the intense heat produced by the combustion process, ensuring the bricks won't crack or break under these conditions. Overall, using insulating fire bricks in rocket stove designs can improve the stove's efficiency and heat transfer, resulting in a more effective and sustainable cooking or heating solution.

- Q: Can insulating fire bricks be used in the construction of heat exchangers?

- Insulating fire bricks have the capability to be utilized in the construction of heat exchangers. These bricks are specifically designed to possess exceptional thermal insulation properties, thereby rendering them ideal for situations where the maintenance or control of high temperatures is necessary. Heat exchangers, which are devices responsible for the transfer of heat between two or more fluids, require insulation in order to prevent any loss or gain of heat during the process. The incorporation of insulating fire bricks in the construction of heat exchangers aids in the reduction of heat transfer to the surrounding environment, ultimately resulting in enhanced energy efficiency and decreased operational expenses. These bricks are capable of withstanding high temperatures, typically reaching up to 3000°F (1650°C), thus making them suitable for various heat exchanger applications, such as furnaces, boilers, and industrial processes. Moreover, insulating fire bricks possess the additional benefits of being lightweight and having low thermal conductivity. This means that they provide effective insulation while also being less bulky and more cost-effective compared to traditional refractory bricks. Consequently, they are easier to handle and install within heat exchanger systems. In conclusion, the utilization of insulating fire bricks in the construction of heat exchangers offers numerous advantages, including improved thermal insulation, enhanced energy efficiency, and reduced expenses.

- Q: Can insulating fire bricks withstand thermal shock?

- Insulating fire bricks possess exceptional thermal insulation properties and are commonly employed in situations where thermal shock does not pose a significant issue. While these bricks can endure moderate temperature fluctuations, they are not explicitly engineered to withstand thermal shock. Thermal shock arises when there is an abrupt alteration in temperature, leading to strain and possible harm to the substance. Insulating fire bricks are more vulnerable to thermal shock in comparison to dense fire bricks, which are explicitly crafted to endure drastic temperature variations. If thermal shock is a concern in your application, it is advisable to contemplate alternative refractory materials that are specially designed to withstand rapid temperature changes.

- Q: Can insulating fire bricks be used in oil refineries?

- Yes, insulating fire bricks can be used in oil refineries. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for various industrial applications, including oil refineries. They help to reduce heat loss, improve energy efficiency, and protect the surrounding equipment and structures from extreme heat.

- Q: Can insulating fire bricks be used for insulation in refractory lining repair?

- Yes, insulating fire bricks can be used for insulation in refractory lining repair. Insulating fire bricks are made from lightweight materials that have excellent thermal insulation properties, making them ideal for use in high-temperature applications such as furnaces, kilns, and other refractory lining structures. These bricks have low thermal conductivity and high resistance to thermal shock, allowing them to effectively insulate and protect the refractory lining from heat, preventing heat loss and reducing energy consumption. Moreover, insulating fire bricks are easy to install and replace, making them a cost-effective choice for refractory lining repair.

- Q: Can insulating fire bricks be used to line industrial boilers?

- Industrial boilers can be lined with insulating fire bricks, which have low thermal conductivity and can minimize heat loss and enhance energy efficiency. These bricks, made of lightweight materials like clay and alumina, possess excellent insulation properties. By lining the boiler's interior with these bricks, the heat generated during combustion can be contained, resulting in greater heating efficiency and decreased fuel consumption. Moreover, these bricks are capable of withstanding high temperatures and thermal shocks, making them ideal for the challenging conditions commonly found in industrial boilers. Overall, utilizing insulating fire bricks as lining material can lead to improved energy efficiency, reduced operating expenses, and enhanced durability of the boiler system.

- Q: What is the typical bulk density of an insulating fire brick?

- The typical bulk density of an insulating fire brick is around 0.6 to 1.2 grams per cubic centimeter (g/cm³).

- Q: How do insulating fire bricks help reduce heat loss through convection?

- Insulating fire bricks are specifically designed to minimize heat loss through convection. They achieve this by creating a barrier that prevents the movement of air and heat transfer. These bricks are made from lightweight refractory materials, which have low thermal conductivity. This means that they are not good conductors of heat and do not allow heat to easily pass through them. When these bricks are used in construction, they create a layer of insulation that effectively reduces heat transfer by convection. Convection is the process of heat transfer through the movement of air or fluid particles. The insulating fire bricks act as a barrier, preventing the free flow of air and interrupting the convective currents. The bricks are designed with small, interconnected air pockets or pores, which trap air inside them. These air pockets act as insulators and minimize the transfer of heat by convection. The trapped air forms a stagnant layer, reducing the movement of air and preventing the heat from escaping or entering the area. By reducing heat loss through convection, insulating fire bricks help to maintain a stable and comfortable temperature within a structure. They are commonly used in applications where heat insulation is essential, such as in industrial furnaces, kilns, and fireplaces. These bricks not only enhance energy efficiency by reducing heat loss but also contribute to fire safety by preventing the spread of heat to adjacent areas.

- Q: Can insulating fire bricks be used in paper mills?

- Yes, insulating fire bricks can be used in paper mills. Insulating fire bricks are commonly used in industries that require high-temperature insulation, such as steel, glass, and ceramics. In paper mills, where processes like drying, heating, and burning occur, insulating fire bricks can be used to line kilns, furnaces, and other equipment to provide insulation and prevent heat loss. These bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for use in paper mills where heat is a crucial component of the manufacturing process. Additionally, insulating fire bricks are lightweight and have low thermal conductivity, allowing for efficient heat retention and energy savings.

- Q: Are insulating fire bricks fire-rated?

- Indeed, insulating fire bricks possess fire-rating. They are purposefully crafted to endure elevated temperatures and furnish superior thermal insulation in diverse applications. Fashioned from a distinct ceramic material with minimal thermal conductivity, these bricks possess the capability to retain heat and impede its transmission to the surroundings. Such attribute endows them with remarkable fire resistance, thereby safeguarding the structures they are employed in. Commonly employed within furnaces, kilns, fireplaces, and other environments characterized by high temperatures, insulating fire bricks play a pivotal role in ensuring fire protection.

Send your message to us

Insulating Fire Brick - Chamotte Refractory Insulated Fire Bricks for Fireplace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords