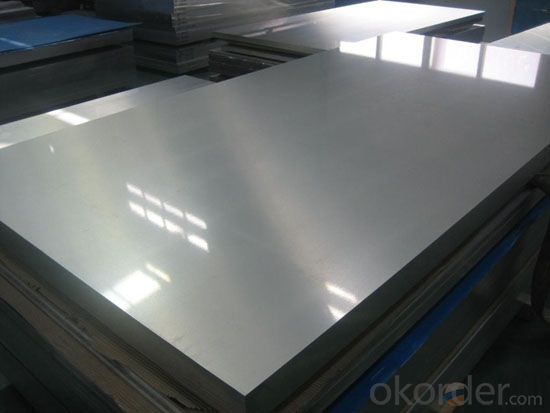

Cold Rolled Steel Sheets Wholesale from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Hot rolled coils/plates

Type: steel coil and steel plates

Material: SS400-Q235-Q345-SPHC

Width:1250mm 1500mm 1800mm 2000mm

HOT-ROLLED COIL/PLATES(Material: SS400-Q235A/B-SPHC) | |||

2.00*1250/1500L | 3.50*1250/1500L | 5.75*1250/1500L | 11.50*1250/1500L |

2.30*1250/1500L | 3.75*1250/1500L | 7.50*1250/1500L | 11.75*1250/1500L |

2.50*1250/1500L | 4.50*1250/1500L | 7.75*1250/1500L | 13.50*1250/1500L |

2.75*1250/1500L | 4.75*1250/1500L | 9.50*1250/1500L | |

3.00*1250/1500L | 5.50*1250/1500L | 9.75*1250/1500L | |

PATTERN-ROLLED COIL/PLATES(Material: Q235A-Q235B) | |||

3.00*1250L | 3.75*1250L | 4.75*1250L | 5.75*1250L |

3.50*1250L | 4.50*1250L | 5.50*1250L | 7.50*1250L |

MIDDEL-PLATE(Material: Q235A/B-Q345A/B) | |||

8*1800/2000L | 16*1800/2000L | 25*1800/2000L | 45*1800/2000L |

10*1800/2000L | 18*1800/2000L | 30*1800/2000L | 50*1800/2000L |

12*1800/2000L | 20*1800/2000L | 35*1800/2000L | |

14*1800/2000L | 221800/2000L | 401800/2000L | |

Name | galvanized steel coil dx52d z gi |

Grade | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518, European Standard, ASTM A792, JIS G3321, JIS G3317 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

ZINC COATING | 40g-275g /m2 |

PAINT THICKNESS | Top:20+-5um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

BASE SHEET | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle), hot dipped A-Z coated steel sheet |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

Applications of cold rolled steel sheet coil :

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Process of cold rolled steel sheet coil :

Pay off reel-double cut shear-welder-notcher-entry accumulator-pre cleaning section-furnace-hot bridle-zinc pot-air knife-after cooler-water quench-dryer- skin pass mill-dryer-tension leveler-dryer-chemical coater-chemical oven-cooler-exit accumulator-oiler-exit shear-tension reel.

Features of cold rolled steel sheet coil :

1) cold rolled steel coils prices is manufactured to have a long durability, strong corrosion resistance and shiny surface.

2) cold rolled steel coils prices features excellent forming properties, paintability, weldability, and is suitable for fabrication by forming, pressing and bending.

c

- Q:Are 101 aluminum sheets suitable for cryo-treating applications?

- No, 101 aluminum sheets are not suitable for cryo-treating applications.

- Q:AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q:What are the environmental benefits of using aluminum sheets?

- The usage of aluminum sheets is associated with numerous environmental advantages. To begin with, aluminum is a highly recyclable substance, meaning it can be recycled repeatedly without losing its quality or properties. This diminishes the need for mining and extracting new aluminum ore, which can lead to deforestation, destruction of habitats, and pollution of water and air. The recycling of aluminum sheets also demands much less energy compared to the production of new ones, resulting in reduced emissions of greenhouse gases and a smaller carbon footprint. Moreover, aluminum sheets are lightweight, making them a more sustainable option in comparison to materials like steel or plastic. Their utilization in various industries like automotive and aerospace can aid in reducing the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This becomes particularly crucial in the context of climate change and the necessity to decrease our reliance on fossil fuels. Additionally, aluminum is resistant to corrosion, durable, and long-lasting, making it a sustainable choice for various applications. Its durability lessens the need for frequent replacements, thereby reducing waste generation. Furthermore, aluminum sheets can be employed in construction to enhance insulation, resulting in energy savings and diminished emissions of greenhouse gases. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This renders it a safe material option for various applications, including food packaging and medical equipment. To summarize, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By selecting aluminum sheets over other materials, we can contribute to the reduction of resource extraction, energy consumption, emissions of greenhouse gases, and generation of waste, while promoting a more sustainable and eco-friendly future.

- Q:Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q:Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for modular construction applications. It is commonly used for building facades, roofing, and structural components in modular construction due to its strength-to-weight ratio and ease of installation.

- Q:Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is a lightweight and durable material that offers a variety of benefits for automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, roofs, and other components. The use of aluminum sheets in automotive applications helps to reduce the overall weight of the vehicle, which improves fuel efficiency and performance. Additionally, aluminum has excellent corrosion resistance properties, making it ideal for withstanding harsh weather conditions and road salt exposure. Furthermore, aluminum can be easily formed and shaped, allowing for complex designs and intricate detailing on automotive parts. Overall, the use of aluminum sheets in automotive applications contributes to the production of lighter, more fuel-efficient, and aesthetically appealing vehicles.

- Q:Can the aluminum sheets be used for manufacturing light reflectors?

- Certainly! Aluminum sheets possess the potential to be utilized in the fabrication of light reflectors. Due to its remarkable reflectivity, aluminum is a frequently employed metallic substance across diverse industrial fields, encompassing the creation of light reflectors. Its exceptional reflectivity facilitates the efficient redirection and intensification of light, rendering it an impeccable material for manufacturing light reflectors for a range of purposes, such as illuminating fixtures, automotive front lights, solar panels, and photographic apparatus. Moreover, the lightweight nature, durability, and resistance to corrosion exhibited by aluminum sheets further augment their aptness for fulfilling this objective.

- Q:Do 101 aluminum sheets have any specific anti-corrosion properties?

- Indeed, specific anti-corrosion properties are possessed by 101 aluminum sheets. When exposed to oxygen, aluminum naturally forms a protective oxide layer on its surface, which acts as a barrier against corrosion. This oxide layer, also referred to as aluminum oxide, exhibits a high resistance to both rust and corrosion. Moreover, the corrosion resistance of 101 aluminum sheets is further enhanced by the addition of small amounts of iron and silicon to the alloy. These sheets are frequently utilized in applications where corrosion resistance is of utmost importance, such as in marine environments, chemical processing plants, and outdoor structures. Nevertheless, it is crucial to acknowledge that although aluminum is highly resistant to corrosion, it can still be susceptible to certain types of corrosion under specific conditions, such as pitting corrosion in chloride-rich environments. Therefore, proper care and maintenance should still be practiced to ensure the durability and effectiveness of 101 aluminum sheets in preventing corrosion.

- Q:Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q:With a project I'm working on, I need to reinforce a small case made of aluminium. My options are to use regular old screws (probably steel) or Stainless Steel screws (much more costly). Just wondering what corrosion will be like? *It will never ever get wet,* so does that mean corrosion will not occur? (to a certain degree, obviously) And would corrosion, since its dry, still be affected by the type of metal used for the screws? The screws need to be strong, and they also need to be purchase-able at a regular hardware store, as I'm not going to go buying just screws on-line. Thanks for any info you can provide.

- Use aluminum rivets

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Steel Sheets Wholesale from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords