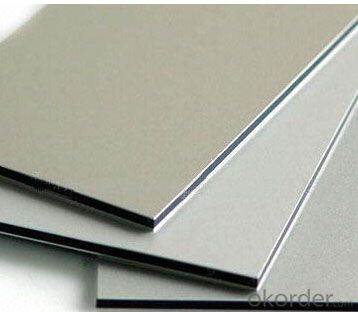

Aluminum Plain Sheets Alloy 1xxx/3xxx/5xxx/6xxx/8xxx Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

1. Specifications

Material : 3003 hot-rolling aluminium coils

thickness:0.1-10mm

width: up to1550mm

length: up to6000(alumimun sheet)

2. Surface quality

Surface without black line, the bright line, clean cut, periodic stain, roller printing defects, such as other gko internal control standards.

3. Application

Ordinary plate , chassis, cabinets , electric productions , transport ,

4. Features

The cheapest price ! , spot goods ,Deliver Faster . good corrosion resistances and excellent formability,

5. Quality

China Nation Standard GB 3880-2006

6. Minimum Order Quantity

5 metirc ton

Packaging & Shipping

Packing

Export packaging fumigation chassis, plank packing paper, coil diameter 1.1---- 1.14 meters, 508 soft-core, 90 degree bending cracks. Single package weigh of coil is 1.5 -2 metic tons, coil is 3-5.7 metric tons .

1000 series aluminum coil is a commercially pure aluminum.

- Q:Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

- Q:Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a popular material choice for elevator interiors due to its various advantageous properties. It is lightweight, durable, and resistant to corrosion, making it suitable for long-term use in elevator applications. Aluminum sheets can be easily fabricated and shaped to fit the dimensions and design requirements of elevator interiors. Additionally, aluminum can be finished with different types of coatings or finishes, such as anodizing or powder coating, to enhance its appearance and provide additional protection. Overall, aluminum sheets are a viable option for elevator interiors and are commonly used in the industry.

- Q:How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets generally exhibit excellent water resistance due to their natural oxide layer, which forms a protective barrier against corrosion. This oxide layer prevents water from penetrating the surface, making aluminum sheets highly resistant to water damage and rusting.

- Q:I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- You can use regular aluminum foil in place of heavy duty foil, but will have use 2-3 layers of the regular foil. Also be careful when wrapping the ribs in the foil that bones do not tear the foil. Heavy duty foil is also wider than regular foil so you may have to join 2 piece of regular foil together. Cut off two-there layers (4-6 pieces) of regular aluminum foil to the length you need, line the layers next to each other, then take the double or triple layers and line them up, fold over the edges 3-4 times to make a seal. The folds need only be a 1/4 - 1/2 inch.

- Q:What are the different surface finishes for aluminum sheets in the aerospace industry?

- Aluminum sheets are widely used in the aerospace industry for constructing aircraft structures due to their lightweight and high strength. Various surface finishes can be applied to these sheets to enhance durability, protect against corrosion, and improve appearance. Anodizing is a commonly used finish that involves coating the aluminum with a protective oxide layer through electrolysis. This process not only improves corrosion resistance but also offers a range of color options and enhances adhesive acceptance. Another popular finish is alclad, which bonds a thin layer of pure aluminum to both sides of an alloy sheet. This provides excellent corrosion resistance and allows for better bonding with composite materials. Chemical conversion coatings are also used in the aerospace industry to provide corrosion resistance and improve paint adhesion. Mechanical finishes like grinding or brushing can be used for aesthetic purposes or to prepare the surface for further treatment. Specialized finishes are employed for specific applications. For areas with high wear resistance requirements, hard anodizing creates a durable surface. For parts needing low friction or high lubricity, a Teflon coating or dry film lubricant can be applied. The choice of surface finish for aluminum sheets in the aerospace industry depends on the specific application's requirements, including factors such as corrosion resistance, adhesion properties, wear resistance, and aesthetic preferences.

- Q:A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- 4Al + 6Na2(C2O4) ---- 2Al2(C2O4)3 + 6KMnO4 ---- 3K2(C2O4) Aluminum oxalate and potassium permanganate are at a 1:3 ratio.... Moles of KMnO4 C = 0.1098 mol/L v = 42.12 ml = 0.04212 L C = n/v n= CV = 0.004624776 mols Therefore moles of aluminum oxylate = 0.001541592 mol = moles of aluminum m= 26.98 g/mol * moles mass of aluminum in oxylate = 0.04159215 g % of initial sample = mass of aluminum / mass of ore = 17.24% aluminum in ore sample Perhaps check my math but the method is for sure correct.

- Q:Can the aluminum sheets be used for manufacturing electrical conductors?

- Indeed, aluminum sheets possess the capacity to be utilized in the production of electrical conductors. Aluminum, being a remarkably conductive metal, falls second only to copper in terms of electrical conductivity. Its application is extensive in various electrical scenarios, encompassing power transmission lines, electrical cables, and wiring. Aluminum sheets can be rolled or extruded, taking on varying shapes and sizes to cater to specific conductor necessities. Furthermore, aluminum exhibits traits of being lightweight, resistant to corrosion, and economically advantageous when compared to alternative conductive materials, hence rendering it a favored option for the manufacturing of electrical conductors.

- Q:what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

- Q:need help choosing an aluminum welder at a descent price also

- What okorder /

- Q:Are aluminum sheets suitable for reflective signage?

- Yes, aluminum sheets are suitable for reflective signage. Aluminum is a versatile material that is commonly used for reflective signs due to its durability, lightweight nature, and ability to reflect light. It has a high reflectivity index, making it ideal for applications where visibility is crucial, such as road signs, traffic signs, and safety signs. Aluminum sheets can be coated with reflective films or paints to enhance their reflective properties, ensuring maximum visibility even in low light conditions. Additionally, aluminum is resistant to weathering, corrosion, and fading, making it a long-lasting and cost-effective choice for reflective signage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Plain Sheets Alloy 1xxx/3xxx/5xxx/6xxx/8xxx Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords