steel pipe professional manufacturer supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | bundles |

| Delivery Detail: | 15-30 days |

| Carbon Steel Seamless Pipes | |||||||

| OD | 10mm-610mm(1/8”-24”) | ||||||

| WT | 2mm-60mm | ||||||

| Length | Random Length: 3.5m-12m, or fixed length 5.8m or as the customer’s requirement. | ||||||

| Standard | ASTM A53, ASTM A106, API 5L, DIN 17175, GOST8731/8732, G3457/G3452 etc. | ||||||

| Material | Q235B, 10#,20#,45#, 16Mn, 15MnV. | ||||||

A53B, A106B, API5L B, A192, A179C, A213-T12, A213-T22, A335-P1, A335-P2, A333 | |||||||

| ST37, ST33, ST37-2, ST35.8 ST52 etc. | |||||||

| Certificate | API certificate and ISO certificate. | ||||||

| Surface | Rust remove, black painting, antirust oil, varnish, 3PE, hot-dip galvanized etc. | ||||||

| Package | By bundles, plastic caps or steel caps, woven, wooden cases or as requirement. | ||||||

| Capability | 6000tons/month. | ||||||

| End | BE/PE. | ||||||

| Advantage | Big diameter and thick wall pipes. | ||||||

| Best price with good quality. | |||||||

| The partner you can trust. | |||||||

| Good service and very patient. | |||||||

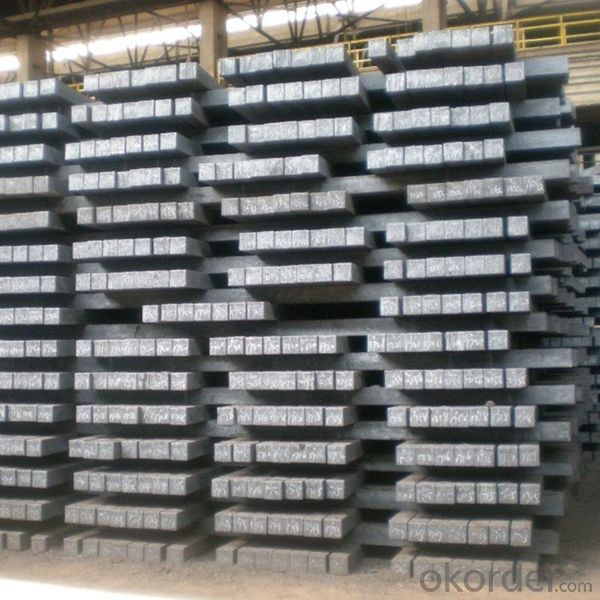

- Q:What are the different shapes available for steel billets?

- Steel billets are manufactured in various shapes to cater to the diverse needs of different industries. Some of the available shapes for steel billets include: 1. Square Billets: These billets have equal sides, forming a square shape. They find extensive use in the construction industry for manufacturing beams, columns, and other structural components. 2. Round Billets: These billets have a circular cross-section and are commonly utilized in the production of seamless pipes, tubes, and rods. They are also employed in the automotive and aerospace sectors for manufacturing various components. 3. Rectangular Billets: These billets have unequal sides, forming a rectangular shape. They are frequently used in the construction industry to manufacture frames, window profiles, and other structural elements. 4. Hexagonal Billets: Hexagonal billets have six equal sides, forming a hexagon shape. They are commonly employed in the production of bolts, nuts, and other fasteners that require a hexagonal shape for proper fitting. 5. Octagonal Billets: Octagonal billets have eight equal sides, forming an octagon shape. They are often used in the manufacturing of special components and tools that require a unique shape for specific applications. 6. Slab Billets: Slab billets have a rectangular cross-section with a larger width compared to their height. They are primarily used for producing flat-rolled steel products such as sheets, plates, and coils. 7. Bloom Billets: Bloom billets have a square or rectangular cross-section with a larger size compared to regular billets. They are commonly utilized in the production of sections, bars, and rails. The choice of steel billet shape depends on the specific requirements of the desired end product and the manufacturing process involved. The versatility of steel billets makes them suitable for a wide range of applications in various industries.

- Q:What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet can vary depending on its intended use and the specific manufacturing process. However, generally speaking, steel billets usually have a rectangular shape with widths ranging from 100mm to 300mm, heights ranging from 100mm to 400mm, and lengths ranging from 6m to 12m. These dimensions allow for easy handling and transportation, as well as flexibility in shaping and forming the steel billet into various end products like bars, rods, or sheets. It's worth noting that these dimensions are not set in stone and can be tailored to meet the specific requirements of the production process or the customer's preferences.

- Q:What are the different types of steel billet surface defects?

- During the manufacturing process, various steel billet surface defects may arise. These defects have the potential to impact the steel's quality and performance, thus necessitating their identification and resolution to safeguard the final product's integrity. 1. Scale: Oxidation during heating and rolling gives rise to a widespread defect known as scale. This defect manifests as a thin layer of iron oxide on the billet's surface, which can be readily eliminated through descaling procedures. 2. Cracks: Another common defect is cracks, which can emerge on the billet's surface. These cracks can be caused by factors such as uneven cooling, excessive stress, or improper handling. Due to their ability to compromise structural integrity, cracked billets necessitate repair or disposal. 3. Pitting: Pitting is characterized by shallow depressions or pits on the billet's surface. It can arise due to impurities in the steel, inadequate cooling, or corrosion. Pitting diminishes strength and heightens susceptibility to corrosion. 4. Lamination: Lamination defects occur when the billet experiences poor bonding during manufacturing, leading to the presence of layers or separation. This defect undermines the steel's mechanical properties, potentially resulting in failure under stress. 5. Inclusions: Non-metallic substances, such as slag, oxides, or other impurities, can become trapped within the billet during manufacturing, causing inclusions. Inclusions weaken the steel and decrease its ductility, rendering it more prone to cracking or breaking. 6. Scratches: Superficial defects like scratches may arise during billet handling or transportation. While they may not significantly impact overall structural integrity, they can concentrate stress in localized areas, potentially leading to failure in specific applications. 7. Decarburization: Decarburization occurs when the billet's surface loses its carbon content during the heating process. This defect reduces hardness and strength in the affected region, impacting the steel's performance. Manufacturers and inspectors must possess knowledge of these various steel billet surface defects to ensure the production of high-quality steel products. Regular inspections, quality control measures, and appropriate corrective actions are vital in minimizing and addressing these defects, thereby guaranteeing the desired steel performance and longevity.

- Q:What are the potential applications of steel billets in the textile aftermarket?

- Steel billets have limited potential applications in the textile aftermarket due to their heavy and rigid nature. However, they can be used as weights for fabric stretching or as support structures for heavy machinery in textile factories.

- Q:How are steel billets used in the manufacturing of gears?

- Steel billets are a crucial component in the manufacturing of gears. Gears are mechanical devices that transmit power and motion by meshing with each other. To ensure the strength, durability, and precision of gears, steel billets are used as the raw material in their production. Steel billets are essentially semi-finished steel products that are obtained through a casting or rolling process. These billets serve as the starting point for the gears manufacturing process. The first step involves forging the steel billets into the desired shape and size. This is done by heating the billets to a specific temperature and then subjecting them to mechanical force, such as hammering or pressing, to shape them into the required gear form. Once the billets are forged into the initial gear shape, they undergo various machining operations to achieve the final product. This includes processes such as milling, drilling, and grinding to remove excess material and create the precise dimensions and features required for the gear. The use of steel billets ensures that the gears are strong enough to withstand the forces and stresses they will encounter during operation. Furthermore, steel billets offer several advantages in gear manufacturing. Steel is a highly durable and strong material, providing the necessary strength and resilience to handle heavy loads and high-speed rotations. It also exhibits excellent wear resistance, allowing gears to maintain their performance and longevity over time. Additionally, steel billets can be easily machined to achieve intricate gear designs, allowing for customization and optimization of gear performance. In summary, steel billets play a vital role in the manufacturing of gears. They serve as the starting material, providing the strength, durability, and precision required for the gears to function effectively. Through forging and machining processes, steel billets are transformed into gears with the necessary shape, dimensions, and features to transmit power and motion efficiently.

- Q:How do steel billets contribute to energy efficiency?

- Steel billets have a significant impact on energy efficiency in various ways: 1. Enhanced production efficiency: Steel billets serve as the initial form of steel utilized in different manufacturing processes. Employing steel billets as the starting material allows manufacturers to achieve higher production efficiency. The uniform size and shape of billets facilitate easier handling, cutting, and shaping, thereby reducing energy consumption during manufacturing. 2. Optimized resource utilization: Steel billets are commonly produced from recycled steel scrap. By employing recycled steel as the raw material, manufacturers minimize the need for extracting and processing virgin iron ore, a highly energy-intensive procedure. This conservation of natural resources helps in reducing overall energy consumption related to steel production. 3. Efficient heat recovery: The manufacturing of steel billets necessitates high temperatures for melting and shaping the steel. However, modern steel plants are equipped with advanced technologies that enable efficient heat recovery. The excess heat generated during the process can be captured and utilized for various purposes, such as generating steam or heating other areas of the plant. This heat recovery system effectively reduces energy wastage and enhances overall energy efficiency. 4. Employment of energy-efficient equipment: Steel billet production often involves the use of heavy machinery and equipment. Manufacturers are increasingly investing in energy-efficient technologies and equipment to minimize energy consumption. For instance, the utilization of more efficient electric arc furnaces or induction heating systems can significantly reduce energy requirements compared to traditional methods. These technological advancements contribute to the overall energy efficiency of steel billet production. In conclusion, steel billets play a pivotal role in enhancing energy efficiency in the steel industry. Their impact is evident in production efficiency, resource optimization, heat recovery, and the utilization of energy-efficient equipment. By minimizing energy consumption, the use of steel billets promotes a more sustainable steel manufacturing process.

- Q:What are the main safety considerations when handling steel billets?

- When handling steel billets, there are several key safety considerations that should be kept in mind to ensure the well-being of workers and prevent accidents. These considerations include: 1. Personal Protective Equipment (PPE): It is crucial for workers to wear appropriate PPE, such as gloves, safety goggles, steel-toed boots, and hard hats. This equipment can provide protection against potential hazards, such as cuts, impact, and flying debris. 2. Proper Lifting Techniques: Steel billets are heavy and can cause strain or injury if lifted incorrectly. Workers should be trained in proper lifting techniques, including bending at the knees, keeping the back straight, and using mechanical aids, such as cranes or forklifts, whenever feasible. 3. Secure Storage and Transportation: Steel billets should be stored and transported in a secure manner to prevent them from falling or shifting, which could lead to crushing or falling hazards. Stacks of billets should be stable and properly secured using appropriate equipment, such as straps or chains. 4. Slip and Fall Prevention: Steel billets, especially when wet or oily, can create slippery surfaces that increase the risk of slips and falls. Proper housekeeping practices, including regular cleaning and the use of anti-slip mats or coatings, can help minimize this risk. 5. Fire and Heat Hazards: Steel billets can reach high temperatures during production or processing. It is important to have adequate fire prevention and firefighting measures in place, such as fire-resistant clothing, fire extinguishers, and proper storage of flammable materials. 6. Hazardous Substances: Some steel billets may be coated with chemicals or have residues that can pose health risks. Workers should be aware of the potential hazards and follow proper handling procedures, including using appropriate ventilation, wearing respiratory protection, and practicing good hygiene. 7. Machine and Equipment Safety: When using machinery or equipment for handling steel billets, it is essential to follow all safety guidelines and precautions, including lockout/tagout procedures, regular maintenance, and proper training on equipment operation. Overall, prioritizing safety when handling steel billets requires a combination of proper training, adherence to safety protocols, and the use of appropriate equipment and protective measures. By following these safety considerations, the risk of accidents and injuries can be significantly reduced.

- Q:How are steel billets unloaded at the destination?

- Steel billets are typically unloaded at the destination using various methods depending on the infrastructure and equipment available. One common method is the use of cranes or forklifts equipped with lifting attachments. These machines are capable of lifting and moving the heavy steel billets from the transport vehicle to the designated storage area or processing facility. In some cases, a specialized unloading facility such as a rail yard or port may be utilized. Here, cranes or gantry systems are often employed to efficiently transfer the steel billets from rail cars or shipping containers onto trucks or storage areas. This method allows for a more streamlined unloading process, especially when dealing with large quantities of steel billets. Another method that is sometimes used is the utilization of conveyor belts or rollers. This method is particularly effective when unloading steel billets from a container or truck where they are arranged in a row. The conveyor belt or roller system allows for a continuous unloading process, with the billets being moved along the conveyor to the desired location. Regardless of the method employed, safety precautions are always taken during the unloading process to ensure the well-being of workers and the prevention of any damage to the steel billets. This may include using proper lifting techniques, securing the billets during transportation, and wearing appropriate personal protective equipment. Overall, the unloading of steel billets at the destination requires careful planning, efficient machinery, and adherence to safety protocols to ensure a smooth and successful operation.

- Q:What are the environmental impacts of steel billet production?

- The environmental impacts of steel billet production include air pollution from emissions of greenhouse gases and particulate matter, water pollution from the discharge of wastewater containing heavy metals and other pollutants, and deforestation and habitat destruction due to the extraction of raw materials such as iron ore and coal. Additionally, the energy-intensive nature of steel production contributes to significant carbon dioxide emissions, contributing to climate change. Efforts are being made to reduce these impacts through technological advancements and the adoption of more sustainable practices.

- Q:How do steel billets contribute to the overall sustainability of a structure?

- There are several ways in which steel billets are crucial for enhancing the overall sustainability of a structure. Firstly, steel is a highly durable material with a long lifespan. This means that structures built with steel billets will have a longer service life and require fewer replacements or repairs. Consequently, the consumption of resources and materials needed for construction is reduced, resulting in minimized waste and conserved energy. Moreover, steel is 100% recyclable, allowing the steel billets to be easily recovered and reused for other purposes at the end of a structure's lifespan. Compared to producing steel from raw materials, recycling steel requires significantly less energy. As a result, greenhouse gas emissions are reduced, and carbon footprints are lower. This approach of a circular economy helps conserve resources and reduces the demand for new steel production, which has a significant environmental impact. Furthermore, steel billets contribute to the overall sustainability of a structure through their strength and versatility. With a high strength-to-weight ratio, steel can support heavy loads with less material, leading to more efficient designs and reduced material consumption. This not only conserves resources but also decreases the carbon emissions associated with the transportation and delivery of steel. Additionally, steel is a non-combustible material, offering structures built with steel billets greater resistance to fires. This enhances the safety and resilience of the structure, reducing the risk of damage or collapse during unforeseen events. Furthermore, the use of steel in structures can contribute to energy efficiency by providing a thermal mass that retains and releases heat, reducing the need for excessive heating or cooling. In conclusion, through their durability, recyclability, strength, and non-combustible properties, steel billets significantly contribute to the overall sustainability of a structure. By incorporating steel into construction, we can minimize waste, conserve resources, reduce carbon emissions, enhance safety, and improve energy efficiency. This ultimately makes structures more environmentally friendly and sustainable in the long run.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

steel pipe professional manufacturer supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords