Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Brief description

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Features

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

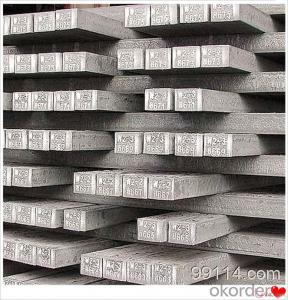

4.Pictures

5.Usage

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6.Detailed specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin : China

Inspection:Third party inspection before loading.

- Q: What are the different shapes and forms of steel billets?

- Depending on their intended use and manufacturing process, steel billets are available in a variety of shapes and forms. Casting is the typical process used to achieve the most common shapes, which include square, rectangular, round, and hexagonal. Square billets are widely used and are often rolled into long products such as bars, rods, and wire. Rectangular billets, with longer sides compared to their width, are also rolled into long products but are typically used for applications that require a larger cross-sectional area. Round billets, as their name suggests, are cylindrical and primarily used for producing seamless tubes, pipes, and other tubular products. The round shape is preferred in these applications as it allows for a more uniform distribution of stresses during manufacturing. Hexagonal billets, with their six sides, are commonly used for forging and machining. Their unique shape provides greater strength and stability, making them suitable for producing high-quality components like bolts, nuts, and other fasteners. In addition to these common shapes, steel billets can also be customized to meet specific requirements in terms of shape and size. Specialized molds or further processing techniques like extrusion or hot rolling can be used to achieve these custom shapes. Overall, the various shapes and forms of steel billets enable the production of a wide range of steel products, each tailored to its specific application and manufacturing process.

- Q: How are steel billets used in the production of automotive components?

- Steel billets are used in the production of automotive components as they are the raw material that is shaped, heated, and then forged or rolled into various shapes and sizes. These billets serve as the building blocks for manufacturing engine parts, suspension systems, chassis components, and other critical automotive parts that require high strength and durability.

- Q: What is carbon accumulation?

- Generally refers to the polycarbonate, PC, is a kind of thermoplastic plastics, good transparency, good mechanical properties, surface hardness, common uses such as CD, plastic glasses, a fence, protective window, public places, vacuum cleaners, coffee machine, juicer barrel, refrigerator shelf, pure such as the bucket.

- Q: How are steel billets used in the manufacturing of mining components?

- Steel billets are a vital raw material used in the production of mining components. These semi-finished steel products act as the initial stage in creating various mining equipment and parts. To begin with, steel billets are heated and then processed through rolling mills to acquire the desired shape, such as bars, rods, or sheets. These specialized forms are then further processed and fabricated to manufacture specific mining components, including pipes, tubes, plates, and beams. Mining components crafted from steel billets offer numerous advantages. The strength, durability, and excellent mechanical properties of steel make it an optimal material for mining equipment exposed to harsh conditions, heavy loads, and extreme temperatures. Steel components can endure the demanding environments found in the mining industry, ensuring their longevity and reliability. Moreover, steel billets can be easily machined, welded, and formed, allowing for the customization of mining components to meet specific requirements. The versatility of steel allows for the production of components with intricate shapes and designs, ensuring their effective performance within mining operations. Furthermore, steel billets can be alloyed with other metals to further enhance their properties. For example, alloying steel with elements like chromium, nickel, or molybdenum can improve corrosion resistance, hardness, and wear resistance, making these components more suitable for mining applications. Overall, steel billets play a crucial role in the manufacturing of mining components by providing a robust and flexible material capable of withstanding the demanding conditions of the mining industry. Their ability to be shaped, customized, and alloyed allows for the production of high-quality and dependable mining equipment and parts that are essential for efficient and safe mining operations.

- Q: What are the different methods of shaping steel billets?

- There are several methods of shaping steel billets, including hot rolling, cold rolling, forging, extrusion, and casting. Each method involves different techniques and processes to shape the steel billets into desired forms and dimensions.

- Q: What is the typical weight of a steel billet?

- The weight of a steel billet can differ based on its size and purpose, resulting in a range of common weights between 1,000 and 5,000 pounds (450 to 2,270 kilograms). This weight range grants flexibility in manufacturing processes and enables diverse applications across industries like construction, automotive, and manufacturing. It is crucial to acknowledge that distinct weight prerequisites might vary according to the steel billet's intended use and specifications.

- Q: How are steel billets used in the production of pipe fittings?

- The production of pipe fittings heavily relies on steel billets, which are a vital raw material. Pipe fittings, which are essential components for connecting and controlling fluid flow in piping systems, are manufactured from steel billets. To make steel billets suitable for manufacturing pipe fittings, they are initially heated to a specific temperature. This heating process makes the billets malleable and easier to work with. Subsequently, the billets undergo a series of processes, such as hot rolling, forging, or extrusion, depending on the desired shape and size of the pipe fitting. During hot rolling, the steel billet is passed through rollers that apply pressure and shape it into a cylindrical form. This particular shape is ideal for producing pipe fittings like elbows, tees, reducers, and couplings. Forging involves subjecting the steel billet to extreme heat and pressure, enabling it to be shaped into complex and custom designs. This method is commonly used to manufacture high-pressure pipe fittings that require exceptional strength and durability. Extrusion is another method employed in the production of pipe fittings. In this process, the steel billet is forced through a die with the desired cross-sectional shape, resulting in pipe fittings with consistent outer and inner diameters. Once the desired shape is achieved, the pipe fittings undergo further processing, such as cutting, threading, or welding, to create the final product. These additional steps ensure that the fittings are prepared for installation and can be securely connected to the piping system. In essence, steel billets are crucial in the production of pipe fittings as the primary raw material. Through processes like hot rolling, forging, or extrusion, they are transformed into a wide range of pipe fittings used in various industries and applications.

- Q: What are the common uses of steel billets?

- Steel billets are commonly used in the production of various steel products such as bars, rods, wire, pipes, and structural components. They serve as the raw material for further processing and shaping, making them essential in industries like construction, manufacturing, and infrastructure development.

- Q: What are the main factors affecting the magnetic properties of steel billets?

- The main factors affecting the magnetic properties of steel billets are the composition of the steel, the crystal structure, the presence of impurities, and the manufacturing process used.

- Q: What are the environmental impacts of manufacturing steel billets?

- The manufacturing of steel billets has significant environmental impacts due to the extraction and processing of raw materials, energy consumption, and waste generation. 1. Raw material extraction: The primary raw materials used in steel billet production are iron ore, coal, and limestone. Extracting these resources often involves mining, which can lead to deforestation, habitat destruction, soil erosion, and water pollution. Additionally, the extraction of iron ore requires large amounts of water, which can strain local water supplies. 2. Energy consumption: Steel billet production requires high temperatures, typically achieved through the combustion of fossil fuels such as coal and natural gas. This process is energy-intensive and contributes to greenhouse gas emissions, including carbon dioxide (CO2) and nitrogen oxides (NOx), which are major contributors to climate change and air pollution. 3. Air pollution: The combustion of fossil fuels in steel production also releases particulate matter (PM), sulfur dioxide (SO2), and other pollutants into the air. These emissions can have detrimental effects on human health, causing respiratory problems and contributing to the formation of smog. 4. Water pollution: Steel manufacturing generates wastewater containing various chemicals and heavy metals. If not properly managed, these pollutants can contaminate water bodies, harming aquatic ecosystems and posing risks to human health. Additionally, the cooling of steel production equipment often requires large amounts of water, leading to water scarcity in some areas. 5. Waste generation: Steel production generates significant amounts of waste, including slag, dust, and sludge. These by-products can contain toxic substances and require careful handling and disposal to prevent soil and water contamination. To mitigate these environmental impacts, various measures can be implemented. These include adopting cleaner production technologies, improving energy efficiency, promoting recycling and reuse of materials, implementing effective waste management practices, and investing in renewable energy sources. Additionally, companies can work towards reducing their overall carbon footprint by implementing carbon capture and storage technologies or transitioning to low-carbon energy sources such as electric arc furnaces powered by renewable energy. Furthermore, government regulations and international agreements can play a crucial role in enforcing environmental standards and promoting sustainable practices in the steel manufacturing industry.

Send your message to us

Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords