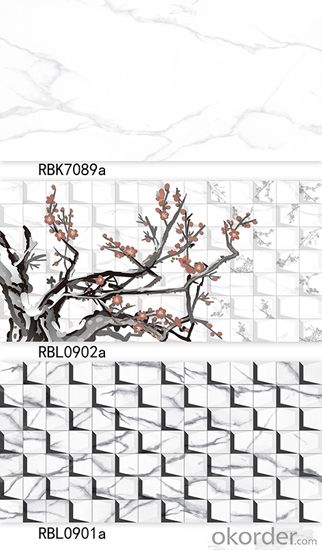

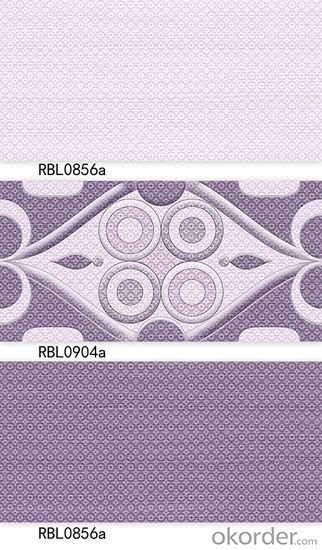

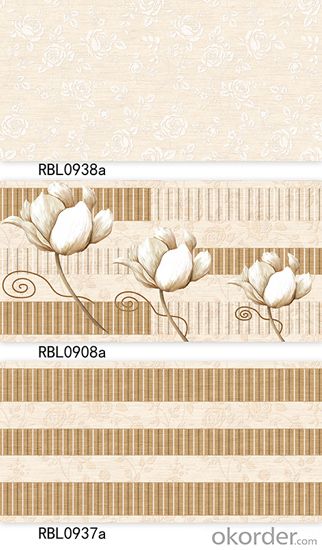

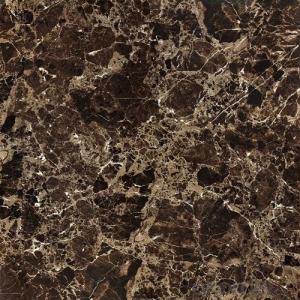

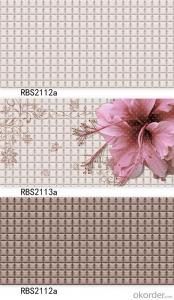

Bathroom & kitchen decorative ceramic wall tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

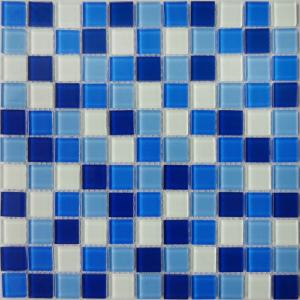

You Might Also Like

Specification

Bathroom & kitchen decorative ceramic wall tiles

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170 g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

- Q: I have a tile floor in my kitchen, and I have tiles in both of my bathrooms, floors and shower walls. Whats is the best way to clean these with out removing the grout?

- Kaboom grout cleaner. Not tub and tile. There is to different ones. They both are very good. If you can find the Kaboom grout cleaner It will do all of it. Other wise use hot water and Just a cap full of the tub and tile cleaner from kaboom ,

- Q: Dose anyone know any decorative tile srtists?

- Check on line or at a tile store. Have fun

- Q: I was thinking of installing ceramic floor tiles for countertop in order to save money. I will use 1/16 joints with a dark tile and dark grout. The edges will be mahogoney or oak. I would think that floor tile would hold up better because it is thicker and more durable. Anybody have experience with installing this type on counters? tx in advance..

- It will hold up, but don't buy a real shiny one with no texture at all. Because everything will show on it and they will eventually scratch. Also a good idea is the dark grout inbetween. Beware of placing mahogony or oak on the edge as it will warp and lose its color eventually from water, I would put a beautiful tile edging instead. Also try to make a design on the backsplash..It really looks georgeous, such as making the tiles diamond shape, and a straight tile border on top and bottom. Absolutely georgeous. My friend has that look and it is so lovely. My daughter in law has ceramic tile counter tops and they are georgeous. The back splash has a beautiful italian fountain design which my son did by himself by purchasing the special tile to place right by the sink. Good Luck on your project.

- Q: how do i start my own tiling business?

- You can use some rendering tools to display your products to customers. You can put all your products in the tool and change different tiles in real room. This will help your business

- Q: I am planning on laying some tile today but not sure when it can be walked on. Also, can I lay some today and start again tomorrow? It is in a small bathroom.

- I usually layout for full tiles splitting the door and full tiles on the wall behind the door measure into the bathroom usally just past the end of the cabinet for full tiles snap a line across your bath then snap a line for full tiles down the wall.Check for square then work your way back out of the bathroom.If you start setting from center and working out you will probably wind up with cut tiles meeting the carpet a serious cut hazard for bare feet.You can walk on the tile the next day.

- Q: are tiles get really dirty fast and i tried everything and i cant get them to stay white could i use bleach?

- Get a product called Black Magic. It's a bleach-like spray that works good on mildew. Follow the directions

- Q: After laying the tile I noticed that they have a hazy patch which appears unglazed in each tile. Is there a substance that I could apply to give the tiles an even look?

- Did you glaze them yourself? If not call the manufacturer....they should send a rep to your home or send a sample of tiles to determine what to do.

- Q: Does floor tile give a lot of heat? I want to get a tile substrate for my leopard gecko, but I don‘t know if it will get warm enough for him. I have an under tank heater, so if I put the tile in will the heat from the under tank heater block or go through the tile?

- Yes, tiles are great. The tile will retain heat, so that's even better. Leo's are found on hard clay in the wild so tiles are the best replica.

- Q: how do you clean up ceramic tiles? they dont seem to shine but look very dull whenever i clean it with water and soap. is there a product i can use to clean them and at the same time leave them shining?

- some tiles just don't have a shiny glazing. if the tile has a texture to it, then really that's all the shine it will have. if you have a piece that wasn't set, just extra, compare it to the set tile. the set tile should have the same shiny glaze as the extra piece. if the extra piece is shiner then there is a bit of a haze on the tile from grout residue. contact the manufacturer if possible and ask for cleaning suggestions. if not possible, start with a bit of vinegar in water and elbow grease.

- Q: Hey!,I want to know how to make handmade tiles that you can paint and stuff....I need step-by-step instructions please !!

- In some measure it depends on how strong you want the tiles to be. Fired clay, in even a tile sense, is usually done at 3600 degrees in a kiln. Then cooled, painted/glazed/ etc. and fired again. At a decent pottery retailer you can find dozens of types of clay, and in fact some that is low fire, or even oven bake, which can be hand painted, and perhaps glazed over with a clear coat and no re-firing, but the strength and durability issue will still exist. Clay for tile, Ceramic or Porcelain, is slab rolled for consistency, Cut precisely, fired in kilns, cooled, then is decorated variously. Some larger houses will sell blanks that one can decorate themselves, even coffee mugs/cups/ bathroom sinks. etc. Obviously with a rolling pin and some risers, at 3/8 or 1/4, you could hand roll the clay and cut it, but then what? Below is a link for a general search to a company that can give you all the info you need in various methods and types of clay used. I spent a lot of $$$ with them in the early part of this decade. Steven Wolf Just my two sense

Send your message to us

Bathroom & kitchen decorative ceramic wall tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords