Aluminum Coils for Sale for ACP, Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

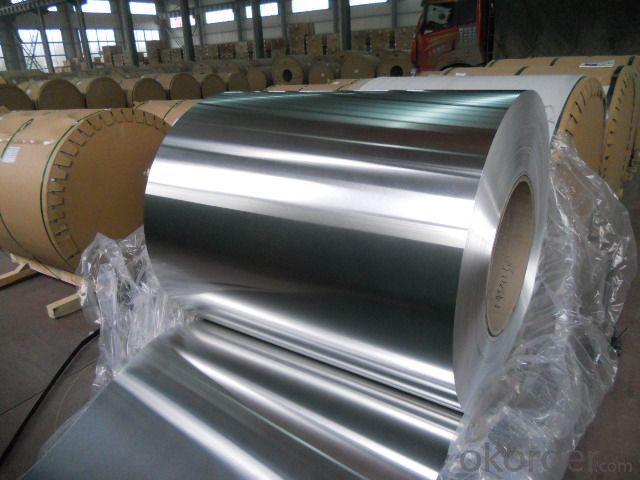

Aluminum Coil for ACP, Aluminum Composite Panel

lProduct Information

| Item | aluminum coil for ACP, Aluminum Composite Panel |

| Alloy Grade | 1100, 3003, 5005 |

| Thickness | 0.3mm~ 3mm |

| Width | 30mm~1850mm |

| Exported Area | USA, UAE, Europe, Asia, Middle East, Africa, South America |

| Min trial order | 2.5 ton each size |

| Tolerance | +2/0mm,thickness tolerance :+0.02/-0.02mm (or according to customers' request) |

lPackaging & Delivery Details

Packaging: Standard seaworthy packing

Delivery: About 25 days after received your advance

lCompany Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building

material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

CNBM has been involved in aluminium products for about a decade. With advanced technology and equipment, our products have been sold to the worldwide including America, Europe, as well as South Asia, etc.

lProduct Images

lCertificates

lFAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

- Q: In my line of work I see aluminum ground lugs, bonding nuts and straps and also neutral bars eat copper up, especially when exposed to the elements. I know how galvanic reaction works between elements under current load, but my question is why do aluminum and copper seem to hate each other more than any other? And, why would they still be required in usage together per NEC code?

- that's a single alternative reaction. The aluminum and the copper swap places, yielding copper and aluminum sulfate. Please notice: the 1st answer describes a chemical equation with nitrate, no longer sulfate. otherwise, this is the perfect format.

- Q: How much does it cost to extract aluminium from its raw ore? Also how much does extracted aluminium sell for? I cannot find this anywhere on the internet. I would really appreciate some help.

- These are the points to think about: The high cost of the process because of the huge amounts of electricity it uses. This is so high because to produce 1 mole of aluminium which only weighs 27 g you need 3 moles of electrons. You are having to add a lot of electrons (because of the high charge on the ion) to produce a small mass of aluminium (because of its low relative atomic mass). Energy and material costs in constantly replacing the anodes. Energy and material costs in producing the cryolite, some of which gets lost during the electrolysis. The key cost of the electrolysis and the cost of electricity. This will depend which country you are in, which you don't tell us. If freely available hydroelectric power is available, this makes a huge difference. IF you are in the US, the costs of extracting aluminium or any metal is 70% to 95% of the current market value. Aluminium is selling at about $1500/tonne, then the cost of extracting it can be around $1200/tonne.

- Q: What types of aluminum coils are there that are designed for particular applications?

- <p>Yes, there are various types of aluminum coils designed for specific purposes. For instance, there are coils for construction, which are often used for roofing and siding. Coils for automotive applications are used in manufacturing car parts. Reflective coils are ideal for heat reflection in industries like food processing. Coils for electrical applications are used in transformers and wiring. Each type has specific properties like thickness, strength, and surface finish tailored to meet the requirements of their respective industries.</p>

- Q: Can aluminum coils be used in automotive body panels?

- Yes, aluminum coils can be used in automotive body panels. Aluminum is lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio, making it an ideal material for automotive applications. Its use in body panels helps improve fuel efficiency and reduce vehicle weight while maintaining structural integrity.

- Q: Can aluminum coils withstand high temperatures?

- Yes, aluminum coils can withstand high temperatures. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making it suitable for applications where high temperatures are involved.

- Q: How are aluminum coils processed and shaped into different forms?

- To shape aluminum coils into various forms, a series of processes is undergone. Initially, the coils are uncoiled and straightened in the uncoiling process, facilitating easier handling and further processing. Following this, a cleaning process is conducted to eliminate any dirt, grease, or impurities present on the coil's surface. This step guarantees a smooth and clean finish for the final product. After cleaning, the coil usually undergoes a sequence of heat treatments to enhance its mechanical properties. This process, known as annealing, entails heating the coil to a specific temperature and gradually cooling it down. Annealing increases the aluminum's ductility, making it more pliable and easier to shape. Once annealed, the coil can be shaped into different forms using various techniques. One prevalent approach is roll forming, where the coil is passed through a series of rollers that gradually bend and shape it according to the desired form. Roll forming is commonly utilized for producing sheets, strips, or tubes. Another popular technique is stamping, which involves utilizing a die and press to cut or shape the aluminum coil into specific shapes. Stamping is frequently employed to create intricate designs or components with precise dimensions. Aside from roll forming and stamping, other methods like extrusion, bending, and welding can also be employed to shape aluminum coils into different forms. These processes enable the production of a vast range of products, including automotive parts, household appliances, and construction materials. Overall, the processing and shaping of aluminum coils encompass a combination of cleaning, heat treatment, and diverse forming techniques. These processes ensure that the aluminum is transformed into the desired form while maintaining its structural integrity and desired properties.

- Q: my homework was to find out how do you get aluminium for rocks! I've been looking around but every web site i've been on only says that aluminium comes from rocks, but it doesn't say how you get it from rocks.e.g you get wool from sheep by shearing of their coat.so if anyone knows how you get aluminum from rocks please tell me i need your help.

- Well, you start with an aluminum rich rock (cheaper to process). The raw ore after physical concentration (removal of secondary minerals) is reacted by an electrolytic process. This means that electricity is used to convert the aluminum ion in the raw rock into the metal aluminum. Sort of like the reverse of a battery, to keep things simple. Aluminum smelters tend to be set up in places with cheap electricity, because the process uses a LOT of electricity. That is why there are several up here in quebec, we have cheap hydro electricity and the government gives decent deals to the smelters on top of the already low market price. Do a search on aluminum smelting to find out more. Not sure what your level of knowledge is so not sure how much you will understand.

- Q: How does the gauge of aluminum coils affect their performance?

- The gauge of aluminum coils refers to the thickness of the aluminum sheet used to manufacture the coil. The gauge is typically measured in terms of its thickness, with a smaller gauge indicating a thicker sheet. The gauge of aluminum coils has a significant impact on their performance. Firstly, the gauge affects the strength and durability of the aluminum coil. Thicker gauges provide increased strength and resistance to bending or warping, making them suitable for applications that require robust and long-lasting coils. On the other hand, thinner gauges are more flexible but may be prone to damage or deformation, making them suitable for less demanding applications. Secondly, the gauge affects the thermal conductivity of the aluminum coil. Thicker gauges have lower thermal conductivity, meaning they are slower to heat up or cool down. This can be advantageous in certain applications where temperature control is crucial, as it helps to maintain a stable environment. Thinner gauges, on the other hand, have higher thermal conductivity, allowing for faster heat transfer. This can be beneficial in applications that require rapid heating or cooling. Thirdly, the gauge affects the weight and cost of the aluminum coil. Thicker gauges are heavier and generally more expensive due to the increased amount of material used. This can be a consideration in applications where weight or cost is a significant factor. Thinner gauges, being lighter and less expensive, can be more suitable for applications where weight reduction or cost efficiency is important. Lastly, the gauge affects the ease of fabrication and formability of the aluminum coil. Thinner gauges are more easily bent, shaped, or formed into desired configurations, making them suitable for applications that require intricate or complex designs. Thicker gauges, while less malleable, can still be formed but may require specialized equipment or processes. In conclusion, the gauge of aluminum coils has a direct impact on their performance. It affects their strength, durability, thermal conductivity, weight, cost, and formability. Therefore, selecting the appropriate gauge for a specific application is essential to ensure optimal performance and efficiency.

- Q: Can aluminum coils be used for sound insulation?

- Indeed, sound insulation can be achieved by employing aluminum coils. By virtue of its high density and capacity to absorb and disperse sound waves, aluminum possesses exceptional qualities for soundproofing purposes. When utilized in the form of coils, aluminum effectively obstructs and reflects sound, thereby diminishing noise transmission and furnishing insulation. Moreover, aluminum coils boast effortless installation and exhibit resistance against corrosion, rendering them a robust and enduring choice for soundproofing applications.

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

Send your message to us

Aluminum Coils for Sale for ACP, Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords