Berger Aluminum Coil

Berger Aluminum Coil Related Searches

Berger Aluminum Trim Coil Aluminum Copper Coil Copper Aluminum Coil Aluminum Alloy Coil Coil Aluminum Aluminum Coil Pipe Polished Aluminum Coil Aluminum Wire Coil Aluminum Tubing Coil Aluminum Ac Coil Aluminum Coil Pe Aluminum Condenser Coil Copper Colored Aluminum Coil Brazing Aluminum Coil Aluminum Gutter Coil Gutter Aluminum Coil Aluminum Evaporator Coil Anodized Aluminum Coil Aluminum A Coil Aluminum Siding Coil Powder Coated Aluminum Coil Aluminum Sheet Coil Colored Aluminum Coil All Aluminum Coil Aluminum Sheet Metal Coil Aluminum Fin Coil Aluminum Tube Coil Aluminum Strapping Coil Coil Coating Aluminum Air Conditioner Aluminum CoilBerger Aluminum Coil Supplier & Manufacturer from China

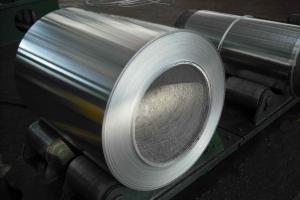

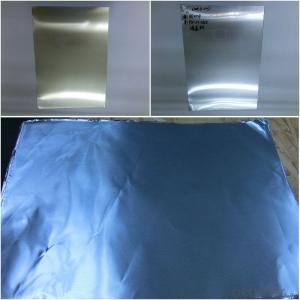

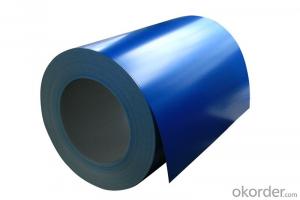

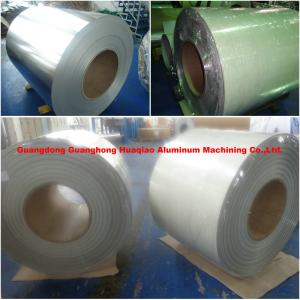

Berger Aluminum Coil is a high-quality product that is widely recognized for its durability and versatility in various industries. This product is made from premium aluminum materials, ensuring that it meets the highest standards of performance and reliability. The product's unique properties make it suitable for a wide range of applications, including construction, automotive, aerospace, and consumer electronics. Its lightweight and corrosion-resistant nature make it an ideal choice for numerous usage scenarios, where strength and longevity are critical factors.Okorder.com is a leading wholesale supplier of Berger Aluminum Coil, boasting a vast inventory that caters to the diverse needs of customers across different sectors. The company prides itself on offering competitive prices and exceptional customer service, ensuring that clients receive the best value for their investment in Berger Aluminum Coil. With a strong commitment to quality and customer satisfaction, Okorder.com has established itself as a trusted source for Berger Aluminum Coil and other related products in the market.