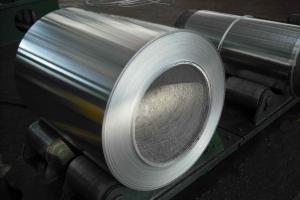

Berger Aluminum Coil - CC Aluminium Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Excellent service

2.Prime quality

3.Cuick delivery

3.ISO 9001:2008

4.BV ,SGS ,

Factory price high quality aluminum coil

Substrates: | Aluminium (1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

Thickness: | 0.08-1.5mm |

Width: | <1800mm |

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: | PVDF >=25micron POLYESTER>=18micron |

Color standard: | E < 2 or it is not obvious by eyeballing |

Pencil hardness: | > 2HB |

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend strength: | >100 times |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils are used in the production of sporting goods primarily for their lightweight and durable properties. They are commonly used in the manufacturing of sports equipment such as baseball bats, tennis rackets, and bicycles. The coils are shaped, formed, and molded into the desired product, providing strength and flexibility while reducing overall weight. This allows athletes to have better control, enhanced performance, and reduced fatigue during sports activities.

- Q: How are aluminum coils protected against oxidation during storage?

- Aluminum coils are protected against oxidation during storage through a variety of methods. One common method is applying a protective coating on the surface of the coils. This coating acts as a barrier, preventing oxygen from coming into contact with the aluminum and causing oxidation. The coating can be a thin layer of oil or a special protective film. Another method is storing the coils in a controlled environment with low humidity. Moisture in the air can accelerate the oxidation process, so by keeping the coils in a dry environment, the risk of oxidation is reduced. Additionally, aluminum coils can be stored in airtight packaging, such as plastic wraps or vacuum-sealed bags. This further minimizes the exposure to oxygen, preventing oxidation. It is also important to handle the coils with care during storage to avoid any damage that could potentially expose the aluminum to the air. Proper packaging and stacking techniques are crucial to ensure the coils remain protected. Overall, a combination of protective coatings, controlled environments, and proper handling techniques are employed to safeguard aluminum coils against oxidation during storage.

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coil typically requires specialized tools to ensure safety and efficiency. Essential tools include a coil cutter for precise cutting, a coil car for easy transportation, and a decoiler for unrolling the coil. Additionally, protective gloves and safety glasses are crucial for personal protection. For more complex tasks, a shear machine or press brake may be necessary for shaping the aluminum. Always follow safety guidelines and use the appropriate tools for the job to prevent accidents and ensure quality work.</p>

- Q: Can aluminum coils be used for heat dissipation purposes?

- Yes, aluminum coils can be used for heat dissipation purposes. Aluminum has excellent thermal conductivity, allowing it to efficiently transfer heat away from a source. Aluminum coils are commonly used in various cooling applications such as air conditioning systems, refrigerators, and heat exchangers to dissipate heat effectively and maintain optimal temperatures.

- Q: What are the different coil cutting options available for aluminum coils?

- Some of the different coil cutting options available for aluminum coils include slitting, shearing, and laser cutting.

- Q: This question asks for the uses or applications of aluminum coil in various industries or contexts.

- <p>Aluminum coil has a wide range of applications due to its lightweight, corrosion resistance, and high thermal conductivity. It is commonly used in construction for roofing and siding, in the automotive industry for parts and heat exchangers, and in the packaging industry for food and beverage cans. Additionally, aluminum coil is utilized in electrical applications such as transformers and electrical wiring due to its excellent conductivity. It is also employed in the manufacturing of household appliances, furniture, and various consumer goods. The coil's malleability makes it suitable for forming into various shapes and sizes, enhancing its versatility across different sectors.</p>

- Q: What does 1060 stand for in 1060 aluminum rolling?

- It means the aluminum content should be above 99.6%.

- Q: What are the common joining techniques used for aluminum coils?

- The common joining techniques used for aluminum coils include welding, adhesive bonding, mechanical fastening, and soldering. Welding is a widely used joining technique for aluminum coils. Different welding methods, such as gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), and laser welding, can be employed to fuse the aluminum coils together. Welding provides a strong and durable joint, ensuring structural integrity. Adhesive bonding is another technique used for joining aluminum coils. It involves the application of a suitable adhesive or bonding agent to join the coils together. Adhesive bonding offers excellent flexibility, as it can join dissimilar materials and create a smooth, aesthetically pleasing surface. Moreover, it distributes stress evenly across the joint, reducing the risk of fatigue failure. Mechanical fastening involves the use of mechanical elements like bolts, screws, rivets, or clips to join the aluminum coils together. This method is relatively simple and cost-effective, allowing for easy disassembly if needed. Mechanical fasteners provide good strength and stability but may require periodic maintenance to prevent loosening over time. Soldering is a technique that uses a low-temperature alloy to join aluminum coils. It involves heating the solder to its melting point and allowing it to flow into the joint, creating a strong bond. Soldering is commonly used for electrical connections or delicate applications where excessive heat can damage the aluminum. However, it may not provide the same strength as welding or mechanical fastening. The choice of joining technique for aluminum coils depends on various factors, including the specific application requirements, desired strength, appearance, and cost considerations.

- Q: What are the various applications and purposes of aluminum coil in different industries?

- <p>Aluminum coil is widely used in numerous applications due to its lightweight, corrosion resistance, and high strength. It is commonly used in construction for roofing and siding, in the automotive industry for body panels and heat exchangers, and in the packaging industry for food and beverage cans. Aluminum coil is also utilized in electrical applications such as transformers and wiring, and in the manufacturing of everyday items like foil and cookware. Its versatility makes it a popular material in various industries.</p>

- Q: Aluminum coil thickness measurement, real-time measurement of aluminum coil thickness value, you can use displacement sensor?

- You should use the eddy current displacement sensor KD2306 if the object is aluminum,

Send your message to us

Berger Aluminum Coil - CC Aluminium Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords