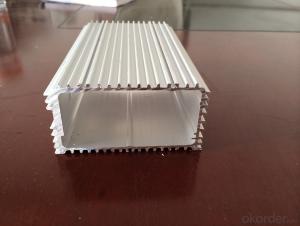

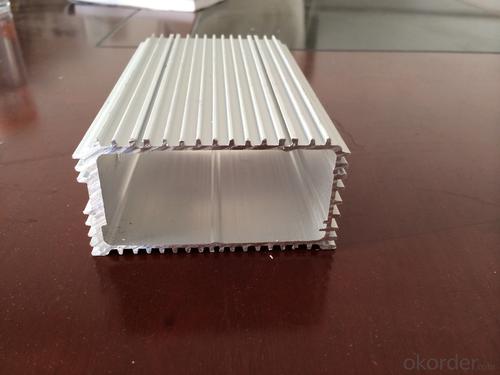

Anodized Aluminium Profile Honeycomb Aluminum Louver for Rolling Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile Anodized for Rooling Door Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile Anodized for Rooling Door:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of Aluminium Profile Anodized for Rooling Door:

Aluminium Profile Anodized for Rooling Door Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- The foil will not burn in a normal oven, it is best to oil it lightly as it can stick.

- Q: What are the different types of aluminum sheets available in the market?

- There are several different types of aluminum sheets available in the market, including plain aluminum sheets, tread plates, perforated aluminum sheets, and decorative aluminum sheets.

- Q: This question asks about the key factors to consider when buying aluminum sheets, including material properties, thickness, surface finish, and other relevant details.

- <p>When purchasing aluminum sheets, consider the following specifications: 1) Alloy type, which determines properties like strength and corrosion resistance; 2) Thickness, measured in millimeters, affecting the sheet's durability and application; 3) Width and length, which should match your project requirements; 4) Surface finish, such as mill finish, anodized, or painted, which impacts aesthetics and protection; 5) Temper, indicating the hardness and formability of the sheet; 6) Certifications, ensuring the sheet meets industry standards; 7) Supplier reputation and customer reviews for quality assurance. These factors will help you select the right aluminum sheet for your specific needs.</p>

- Q: Can aluminum sheets be used for packaging applications?

- Indeed, packaging applications can utilize aluminum sheets. This material, known for being lightweight, corrosion-resistant, and long-lasting, proves to be an ideal selection for packaging diverse products. It effectively shields against moisture, oxygen, and light, thus ensuring the preservation of packaged goods' quality and freshness. The malleability of aluminum sheets allows for effortless customization and branding, as they can be easily shaped into various forms and sizes. Consequently, they find widespread use in packaging food and beverages, pharmaceuticals, cosmetics, and other consumer goods. Moreover, aluminum sheets promote sustainability as they are recyclable, further enhancing their suitability for packaging purposes.

- Q: Can aluminum sheets be used for sound insulation?

- Aluminum sheets possess a certain degree of effectiveness in sound insulation. Although aluminum is not as proficient in soundproofing as materials such as rubber or foam, it can still offer a certain level of sound insulation if utilized appropriately. One can employ aluminum sheets as a barrier or partition in walls, ceilings, floors, or other surfaces to decrease the transmission of sound waves. Nevertheless, it is noteworthy to mention that attaining optimal outcomes might require the inclusion of supplementary soundproofing materials or techniques.

- Q: What safety measures should be considered when handling large quantities of aluminum sheets?

- <p>When working with large amounts of aluminum sheets, it's important to take several precautions. Always wear protective gloves and eyewear to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper lifting techniques to avoid back injuries, and never exceed the weight limits of any equipment. Store aluminum sheets in a dry, cool place to prevent corrosion. Be cautious of static electricity buildup, which can be a fire hazard, especially in dry conditions. Finally, be aware of the risk of aluminum dust igniting, so avoid open flames and sparks near stored or processed aluminum sheets.</p>

- Q: avaliable in the uk preferably in a high street store and preferably anti-perperant aswell

- Are you allergic to aluminum or are you refusing to use it because it is not natural? Aluminum has solid research to back its antiperspirant ability. As long as the deodorant or antiperspirant is well-formulated, it is good. There is no best. You should make a search on Amazon UK with key word like natural or organic deodorant or antiperspirant because those terms usually filter out aluminum ones. But, whether or not it will be effective is a different story.

- Q: Can 101 aluminum sheets be anodized in different colors?

- Yes, 101 aluminum sheets can be anodized in different colors.

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile method that uses a high-pressure stream of water mixed with an abrasive material to cut through various materials, including metals like aluminum. The waterjet cutting process is effective for aluminum because it does not generate heat, which can potentially deform or damage the metal. It also provides high precision and accuracy, allowing for intricate shapes and designs to be cut with ease. Waterjet cutting is commonly used in industries that require precise and clean cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

Anodized Aluminium Profile Honeycomb Aluminum Louver for Rolling Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords