Aluminum Sheets Minneapolis Mn - Aluminio Sliding Window Interior Window Frame Window Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

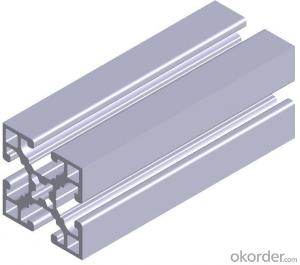

Structure of Aluminio Sliding Window Interior Window Frame Window Aluminum Profiles Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminio Sliding Window Interior Window Frame Window Aluminum Profiles:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminio Sliding Window Interior Window Frame Window Aluminum Profiles:

Aluminio Sliding Window Interior Window Frame Window Aluminum Profiles Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What are the different methods for perforating aluminum sheets?

- There are several methods for perforating aluminum sheets, including laser cutting, punching, drilling, and waterjet cutting. Each method has its own advantages and is chosen based on factors such as desired hole size, shape, precision, and production volume.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: What are the surface treatment requirements for aluminum sheets in the food industry?

- In the food industry, aluminum sheets are commonly used due to their excellent corrosion resistance and lightweight properties. However, certain surface treatment requirements need to be met to ensure the safety and quality of the food products. Firstly, aluminum sheets used in the food industry should undergo a cleaning process to remove any impurities or contaminants. This can be achieved through various methods such as chemical cleaning, alkaline cleaning, or mechanical cleaning. The purpose is to eliminate any potential sources of contamination that could affect the food's taste, odor, or safety. Furthermore, the surface of the aluminum sheets should be properly finished to prevent any interactions between the metal and the food. Anodizing is a popular surface treatment method, which creates a protective oxide layer on the aluminum surface. This layer not only enhances corrosion resistance but also provides a barrier against any potential migration of aluminum ions into the food. Additionally, it is crucial to ensure that the surface treatment materials used are food-grade and compliant with relevant regulations. The food industry has specific guidelines and standards in place to ensure the safety and suitability of materials that come into contact with food. Therefore, the surface treatment process should adhere to these standards to prevent any health hazards or contamination risks. Regular inspection and maintenance of the surface treatment are also necessary to guarantee its effectiveness over time. This includes monitoring the integrity of the protective layer, identifying any signs of wear or damage, and taking appropriate actions to address them promptly. In summary, the surface treatment requirements for aluminum sheets in the food industry include thorough cleaning, proper finishing, the use of food-grade materials, and regular maintenance. These measures are crucial to ensure the safety and quality of the food products and to comply with industry regulations and standards.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding usually overlays two pieces together and presses them, heating them to melting state through current, you can try multiple sheets.

- Q: What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets can vary depending on the specific requirements and applications. Generally, aluminum sheets can be found in a wide range of thicknesses, ranging from as thin as 0.006 inches (0.15mm) to as thick as 0.5 inches (12.7mm) or even thicker in some cases. However, it is important to note that the availability of specific thicknesses may vary depending on the supplier or manufacturer. Additionally, custom thicknesses can often be obtained through specialized fabrication processes.

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a good conductor of electricity and is commonly used in electrical grounding systems due to its low resistance and cost-effectiveness.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- Aluminum

Send your message to us

Aluminum Sheets Minneapolis Mn - Aluminio Sliding Window Interior Window Frame Window Aluminum Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords