Aluminum Sheets in Michigan - Aluminium Profile Industrial for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

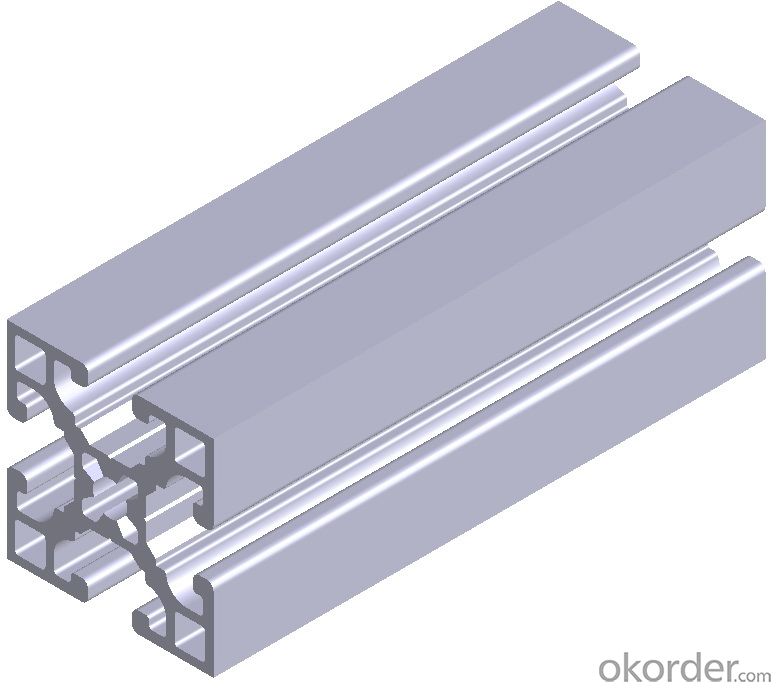

1.Structure of Aluminium profile Industrial for Doors and Windows Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium profile Industrial for Doors and Windows:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

3.Aluminium profile Industrial for Doors and Windows Images:

4.Aluminium profile Industrial for Doors and Windows Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different joining methods for aluminum sheets?

- There are several different joining methods for aluminum sheets, each with its own advantages and considerations. Some of the common joining methods for aluminum sheets include: 1. Welding: Welding is a popular method for joining aluminum sheets. It involves melting the aluminum sheets and fusing them together with the help of a filler material. Welding can be done using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding. It provides strong and durable joints, but it requires skilled labor and can be time-consuming. 2. Adhesive bonding: Adhesive bonding is another method commonly used for joining aluminum sheets. It involves applying a specialized adhesive or glue to the surfaces that need to be joined. Adhesive bonding offers several advantages such as excellent corrosion resistance, uniform distribution of stress, and the ability to join dissimilar materials. However, it requires proper surface preparation and can be affected by temperature and humidity. 3. Mechanical fastening: Mechanical fastening involves using various mechanical fasteners such as bolts, screws, rivets, or clips to join aluminum sheets. This method is relatively simple, cost-effective, and allows for easy disassembly if required. However, it may create stress concentrations around the fasteners, and the joints may not be as strong as those created by welding. 4. Friction stir welding: Friction stir welding is a relatively new joining method that is gaining popularity for aluminum sheets. It involves rotating a non-consumable tool along the joint line, generating friction and heat that softens and joins the aluminum sheets. Friction stir welding offers benefits such as high joint strength, low distortion, and a defect-free weld. However, it requires specialized equipment and is limited to certain sheet thicknesses. 5. Clinching: Clinching is a cold joining method that involves deforming the aluminum sheets using a punch and die without melting them. The sheets are pushed together under high pressure, creating a mechanical interlock. Clinching is a fast and cost-effective joining method that does not require additional materials, but it may result in visible deformation on the surface. It is essential to consider factors such as joint strength, corrosion resistance, aesthetics, production cost, and specific application requirements when choosing a joining method for aluminum sheets. Each method has its own advantages and limitations, so selecting the most suitable technique depends on the specific needs of the project.

- Q: What is the thickness of the aluminum sheets?

- Depending on the specific product or application, the thickness of the aluminum sheets may vary. Aluminum sheets come in a diverse range of thicknesses, typically varying from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm) or possibly even thicker. The suitable thickness will be determined by the specific requirements and intended usage of the aluminum sheet.

- Q: Aluminum and oxygen gas react to produce aluminum oxide

- Aluminium oxide is Al2O3, so there are 3 oxygen atoms for every 2 aluminium atoms. Divide 75 by the relative atomic mass of oxygen (15.9994). That is proportional to the number of oxygen atoms. Then divide by 3 and multiply by 2. This gives a number proportional to the number of aluminium atoms. Then multiply this by the relative atomic mass of aluminium (26.981529) to give the mass of aluminium required in grams.

- Q: Are the aluminum sheets suitable for manufacturing transportation containers?

- Yes, aluminum sheets are suitable for manufacturing transportation containers. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal material for containers used in transportation. It offers high strength-to-weight ratio and can withstand harsh conditions, making it suitable for various modes of transportation such as trucks, trains, and ships. Additionally, aluminum is recyclable, making it an environmentally friendly choice for container manufacturing.

- Q: Not just cans. How is aluminum recycled and what is the process. Not the scientific formula! How its done entering the plant.

- First, aluminum is shredded. It is then melted and turned into molten aluminum. Once it becomes molten, the used aluminum does not differ from new aluminum. It is then molded into the new product. Recycling aluminum is much more energy efficient than melting new ore into aluminum because it takes three times the energy to produce than if it was recycled.

- Q: how to distinguish the physical property of copper sheet from the one of aluminum sheet?

- physical property: copper sheet: golden, heavy, aluminum sheet: white, light.

- Q: Are the aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it an ideal choice for outdoor use. Additionally, aluminum sheets are lightweight, durable, and have excellent thermal and electrical conductivity, further enhancing their suitability for various outdoor applications.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- West It is all about the ride that both frames offer. Both frames are durable. There is a slight weight difference. But both are excellent frame materials. Steel is amore forgiving and strong material. It clearly provides the best overall ride characteristics. Aluminum is lighter, not quite as durable, but does not rust. It's ride is far harder than steel. To many it is far to harsh to ride distances on. I have owned multiple steel and aluminum frames. I liked them both... they never impacted me on distance rides. I loved the steel bikes ride. I like the look and stiffness of the aluminum frames. I would probably choose an aluminum frame over steel..... Soccerref

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a widely used material in the food industry due to its various beneficial properties. It is non-toxic, non-reactive, and corrosion-resistant, making it safe to use with food. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of food packaging and cooking applications. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during cooking or baking. It is also impermeable to light, moisture, and oxygen, providing a protective barrier to maintain the freshness and quality of food. Overall, aluminum sheets are a popular choice for food contact applications due to their safety, versatility, and durability.

- Q: I am looking to purchase a pressure cooker and the size that i want comes in aluminum while alot of the others are made from stainless steel. I am wondering if the metal makes a difference in the funtionality and if one doesn't stand up as well as the other.

- Aluminum Pressure Cooker

Send your message to us

Aluminum Sheets in Michigan - Aluminium Profile Industrial for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords